Coal Ball Packaging Machine Manufacturer in China for Efficient Solutions

Are you in the market for a Coal Ball Packaging Machine? I understand the challenges of finding reliable and efficient equipment. As a manufacturer based in China, I’ve dedicated myself to producing top-quality packaging solutions that meet diverse business needs. With my Coal Ball Packaging Machine, you're getting more than just machinery; you're investing in enhanced efficiency and productivity. Designed to handle various materials, this machine ensures precision packing and can significantly reduce labor costs. I take pride in the durability and performance of my products, which undergo rigorous quality checks before making their way to you. By choosing my equipment, you're not only streamlining your operations but also partnering with a manufacturer who cares deeply about your success. Let’s elevate your packaging process together!

Coal Ball Packaging Machine Now Trending Custom Solutions,

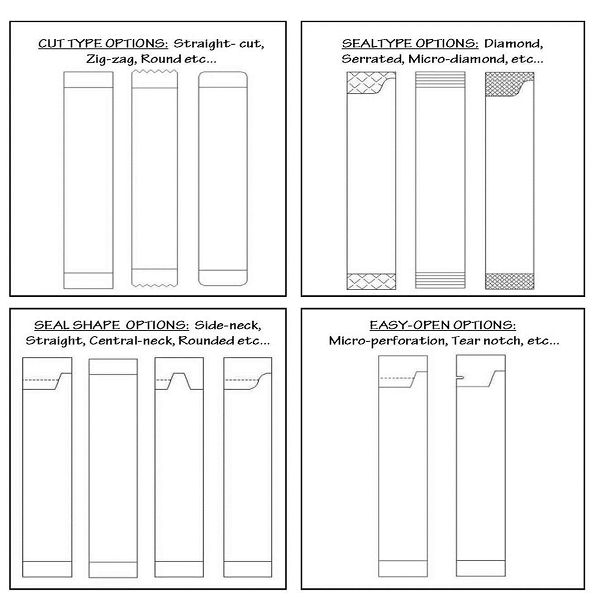

In today's market, the demand for efficient and innovative packaging solutions is on the rise, and coal ball packaging machines are leading the trend. These specialized machines not only enhance productivity but also ensure the quality and consistency of packed products. As manufacturers seek to optimize their operations, custom solutions for coal ball packaging have become essential. Tailored designs can address specific production needs, comply with varying regulations, and provide unique features that boost usability and efficiency. Adopting a coal ball packaging machine equipped with advanced technology can significantly benefit global procurement strategies. Automation, precision, and adaptability are key factors that help businesses meet the increasing demands of customers while minimizing labor costs. By investing in modern packaging machinery, companies can improve their logistics and supply chain management, leading to a quicker turnaround time and a competitive edge in the global market. As the industry moves towards larger-scale production and customization, the need for bespoke packaging solutions has never been more critical. Companies are encouraged to leverage these advancements to streamline operations and enhance product appeal, thereby tapping into new markets and expanding their reach. The current trend demonstrates that innovation in packaging machinery not only supports growth but also fosters sustainability in production practices, making it an ideal solution for forward-thinking enterprises.

Coal Ball Packaging Machine Now Trending Custom Solutions

| Machine Model | Features | Customization Options | Applications | Production Capacity |

|---|---|---|---|---|

| Model A1 | Automatic sealing, PLC control | Custom sizing, Logo printing | Food industry, Chemical packaging | 200 units/hour |

| Model B2 | Multi-functional, Easy to operate | Custom colors, Variety of bag types | Pharmaceuticals, Agriculture | 150 units/hour |

| Model C3 | Energy-efficient, Compact design | Adjustable speed, Manual override | Coal industry, Construction | 250 units/hour |

| Model D4 | Robust structure, High-speed operation | Custom interfaces, Remote monitoring | Mining, Heavy industry | 300 units/hour |

Related Products