Wholesale Eye Drop Cartoning Packing Machine Manufacturers

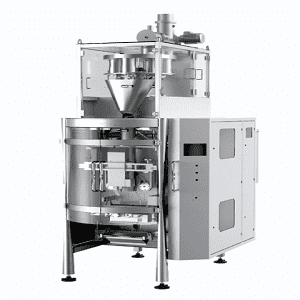

When it comes to packaging eye drops, efficiency and reliability are key. Our Eye Drop Cartoning Packing Machine comes designed to meet the needs of manufacturers looking for fast and precise solutions. With our machine, you can streamline your production process, ensuring each carton is packed flawlessly without compromising on quality. As a wholesale provider, we understand the challenges faced by production lines. Our machine caters specifically to high-volume operations, allowing you to save time and reduce labor costs. The intuitive controls make it easy to operate, even for those with limited experience. Choosing our Eye Drop Cartoning Packing Machine means investing in a product that will enhance your manufacturing capabilities. We pride ourselves on delivering top-notch machines tailored for companies like yours. Whether you’re a small manufacturer or a larger enterprise, our machine is designed to elevate your production efficiency and meet the demands of the market effectively.

Eye Drop Cartoning Packing Machine Where Service Meets Innovation Service Backed by Expertise

In the fast-evolving landscape of the pharmaceutical industry, the demand for efficient and reliable packaging solutions has never been greater. Eye drop cartoning packing machines play a crucial role in ensuring that these delicate products are stored and delivered safely. Our latest innovations in machine design have transformed traditional methods, combining cutting-edge technology with user-friendly interfaces. These advancements not only enhance operational efficiency but also ensure the quality and integrity of the eye drop products. Our service philosophy centers around the idea of blending innovation with exceptional customer support. Each machine is backed by a team of experts who understand the nuances of the packaging process. From installation to maintenance, we provide comprehensive support to ensure optimal performance. Our commitment to quality service means that clients can focus on their core business operations with the assurance that their packaging needs are in capable hands. Choosing the right packing machine can significantly influence the success of your product in the market. The integration of advanced technology in our eye drop cartoning systems leads to reduced labor costs, minimized waste, and enhanced productivity. With a focus on sustainability and efficiency, we empower global procurement professionals to make informed decisions that will drive their businesses forward. Experience the difference where service meets innovation, tailored to meet the unique needs of the pharmaceutical sector.

Eye Drop Cartoning Packing Machine Where Service Meets Innovation Service Backed by Expertise

| Feature | Description | Benefit | Application |

|---|---|---|---|

| Automated Cartoning | Fully automatic cartoning process for eye drop bottles | Increased efficiency and reduced labor costs | Pharmaceutical and cosmetic industries |

| Customizable Designs | Ability to accommodate various carton sizes and designs | Flexibility to meet different product requirements | Research and development of new products |

| Real-time Monitoring | Integrated monitoring system for process control | Ensures quality and compliance with industry standards | Quality assurance in production |

| User-friendly Interface | Intuitive control panel for easy operation | Reduces training time for operators | Operational efficiency in manufacturing plants |

| Robust Construction | Sturdy design to withstand heavy production demands | Longevity and low maintenance costs | High-volume production environments |

Related Products