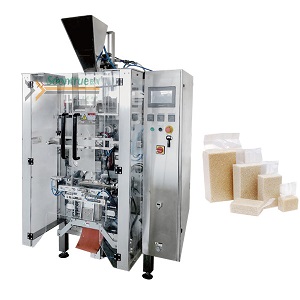

Wholesale Full Automatic Food Packing Machine Manufacturers for Efficient Packaging

As a B2B purchaser, I understand the importance of efficiency and quality in food packaging. That's why I’ve chosen the Full Automatic Food Packing Machine, which offers unparalleled performance for wholesalers and manufacturers alike. This state-of-the-art machine streamlines the packing process, reducing labor costs and increasing output. With its user-friendly interface and customizable settings, I find it incredibly easy to operate and adapt to different product types. It minimizes waste, ensuring that every portion is perfectly packaged, which is crucial for maintaining freshness and regulatory compliance. The durable construction means it’s built to last, making this investment a smart choice for any food production line. Trust me, when working with this Full Automatic Food Packing Machine, I feel confident knowing I'm enhancing our operational efficiency and boosting product quality. It’s the right fit for those looking to elevate their packaging solutions in a competitive market.

Full Automatic Food Packing Machine Products Where Innovation Meets 2025

In the fast-evolving world of food packaging, innovation is the key to staying competitive. As we look toward 2025, the need for full automatic food packing machines is more critical than ever. These advanced machines not only enhance efficiency and productivity in food processing plants but also ensure that products are packaged safely and securely, preserving quality and extending shelf life. With the integration of smart technologies, such as AI and IoT, modern packing machines provide real-time monitoring and data analytics, allowing businesses to optimize their operations and reduce waste. Global procurement buyers are increasingly seeking solutions that not only meet their packaging needs but also drive sustainability. The new generation of packing machines is designed with eco-friendly materials and energy-efficient processes, catering to the growing demand for sustainable practices within the food industry. By investing in these innovative technologies, businesses can improve their environmental footprint while maintaining high production standards. As we transition into this new era of food packaging, it is essential for global buyers to remain updated on the latest trends and technologies. Emphasizing automation and innovation will not only streamline the packing process but also open opportunities for customization and cost reduction. Embracing these advancements will position companies at the forefront of the market, ready to meet the challenges of tomorrow's food packaging landscape.

Full Automatic Food Packing Machine Products Where Innovation Meets 2025

| Model | Features | Speed (bags/min) | Power (kW) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|

| FP-2025-A | Fully automatic, PLC control, multi-purpose | 120 | 2.5 | 450 | 800 x 600 x 1600 |

| FP-2025-B | Touch screen, easy maintenance, high efficiency | 150 | 3.0 | 500 | 850 x 650 x 1650 |

| FP-2025-C | Compact design, energy saving, adjustable settings | 100 | 2.0 | 400 | 700 x 550 x 1550 |

| FP-2025-D | Automatic feeding, high precision, safety features | 130 | 3.5 | 480 | 820 x 620 x 1620 |

| FP-2025-E | Robust construction, user-friendly interface, fast setup | 140 | 2.8 | 470 | 810 x 610 x 1610 |

Related Products