Kraft Packing Machine Manufacturer in China: Quality Solutions for You

As someone deeply involved in the packaging industry, I understand the crucial role a reliable **Kraft Packing Machine** plays in streamlining operations. Whether you're a small business or a large manufacturer, finding the right equipment is essential for efficiency. I’ve personally seen how these machines from **China** can enhance your packaging process, providing robust solutions tailored to your specific needs. Working directly with **manufacturers**, I can attest to their commitment to quality and innovation. Their machines offer durability and performance, allowing you to maintain high production standards while reducing waste. By integrating advanced technology, these Kraft packing machines ensure that your products are securely packaged and ready for distribution. If you're in search of an effective way to elevate your packing processes, consider a Kraft packing machine. It’s not just equipment; it’s an investment in the future of your business. Let's elevate your packaging game together!

Kraft Packing Machine. Service Service Backed by Expertise

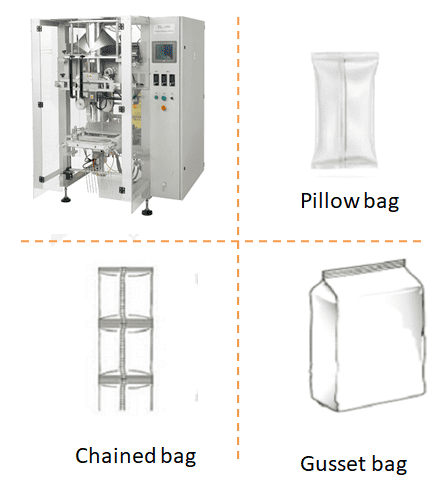

In today’s rapidly evolving packaging industry, efficiency and reliability are paramount. Kraft packing machines stand out as a critical component for businesses seeking to enhance their packaging processes. These machines are designed to handle various materials with precision, ensuring that products are securely packed and ready for distribution. With their robust build and innovative technology, Kraft packing machines not only streamline operations but also reduce labor costs and minimize waste, making them an excellent investment for manufacturers aiming to improve productivity. Choosing a service partner with deep expertise in machinery maintenance and support can significantly impact the longevity and performance of your Kraft packing machines. Professionals with extensive experience in the field offer comprehensive services, from installation and calibration to regular maintenance and troubleshooting. This ensures that your equipment operates at optimal efficiency, thereby safeguarding your production timelines and meeting customer demands consistently. By collaborating with a knowledgeable service provider, businesses can navigate the complexities of machinery care, ensuring minimal downtime and maximizing output. Ultimately, investing in a quality Kraft packing machine, backed by expert service, positions companies to meet the challenges of a competitive market. Understanding the nuances of your packaging requirements and aligning them with the capabilities of advanced machinery is crucial for sustaining growth and achieving operational excellence. Embracing such solutions not only enhances your packaging strategy but also reinforces your commitment to quality and efficiency in every product you deliver.

Kraft Packing Machine. Service Service Backed by Expertise

| Feature | Description | Benefits |

|---|---|---|

| High Speed | Capable of achieving up to 200 packs per minute. | Increases production efficiency significantly. |

| Versatile | Suitable for various packaging materials like plastic, metal, and paper. | Adapts to different product requirements easily. |

| User-Friendly Interface | Intuitive touchscreen controls for easy operation. | Reduces training time for operators. |

| Robust Design | Constructed with high-quality materials for durability. | Minimizes maintenance and replacement costs. |

| Energy Efficient | Designed to consume less power during operation. | Lowers operational costs in the long run. |

Related Products