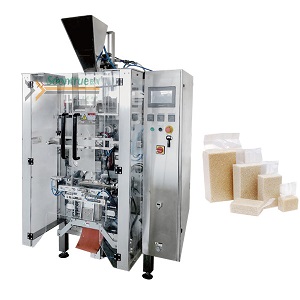

Top China Manufacturer of High-Quality Rice Packing Machines

When I first started exploring rice packing machines, I quickly realized how important it is to find a reliable manufacturer, especially from China. The efficiency and precision of these machines caught my attention, as they streamline the packing process, ensuring quality and minimizing waste. I've seen firsthand how a well-designed packing machine can boost productivity in any rice processing business. Plus, with advancements in technology, many of these machines come equipped with user-friendly interfaces and customizable settings, making them suitable for various packing needs. Working with a reputable Chinese manufacturer means I can expect not just quality but also competitive pricing, which is crucial for staying ahead in today’s market. If you’re serious about enhancing your packing operations, investing in a rice packing machine could be a game changer. Let’s take your rice production to the next level together!

Rice Packing Machine Is The Best For the Current Year

In the ever-evolving landscape of the packaging industry, rice packing machines have emerged as essential tools for manufacturers aiming to enhance efficiency and maintain product quality. As global demand for rice continues to rise, investing in advanced packing technology is crucial for companies seeking to streamline their operations. The latest innovations in rice packing machines not only optimize the packaging process but also improve precision and reduce waste, making them the best choice for businesses in the current year. Modern rice packing machines are equipped with cutting-edge automation features that minimize human intervention and enhance productivity. These machines offer customizable settings that cater to various packaging formats and sizes, enabling businesses to meet diverse market needs effectively. Furthermore, many models incorporate robust quality control systems that ensure packaging integrity, thereby preserving the freshness and taste of the rice. By adopting these advanced solutions, manufacturers can expect to improve their operational efficiency and significantly cut down on costs in the long run. As the industry continues to evolve, it's imperative for businesses to stay ahead of the curve by investing in state-of-the-art equipment. The benefits of upgrading to the latest rice packing machines are clear: increased productivity, reduced operational costs, and enhanced product quality. For global buyers, now is the opportune time to explore advanced packaging solutions that can set their operations apart from competitors and meet the growing demands of the market.

Rice Packing Machine Is The Best For the Current Year

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Automated Packing | Fully automated system with real-time monitoring. | Increases efficiency and reduces labor costs. | Commercial rice processing facilities. |

| Adjustable Packing Sizes | Capable of packing different sizes (1kg, 5kg, 10kg). | Flexibility to meet varying customer demands. | Retail and wholesale distribution. |

| High-Speed Operation | Can pack up to 50 bags per minute. | Increases productivity and reduces wait times. | Large scale production lines. |

| User-Friendly Interface | Intuitive controls and touchscreen operations. | Easier training for staff and operation management. | All types of rice packaging businesses. |

| Durability | Built with high-quality materials for long-lasting use. | Reduced maintenance costs and downtime. | Manufacturing and export facilities. |

Related Products