Affordable Tea Bag Packing Machine Price for Wholesale Manufacturers

When I first explored the market for tea bag packing machines, I noticed a significant variation in prices, especially when considering wholesale options from different manufacturers. The right machine can enhance my production efficiency and ensure high-quality packaging, which is essential in today’s competitive market. I’ve found that sourcing directly from reliable manufacturers not only helps in reducing costs but also allows for customization options that can meet specific needs. The price of tea bag packing machines generally reflects the quality and features, so it’s important to assess what fits best for my business. Whether I am looking for a basic model or a fully automated solution, it's crucial to evaluate the long-term return on investment. Partnering with the right suppliers ensures I get the best price without compromising on the quality of the machines. This way, I can stay competitive while delivering top-notch products to my customers.

Tea Bag Packing Machine Price Products Where Innovation Meets 2025

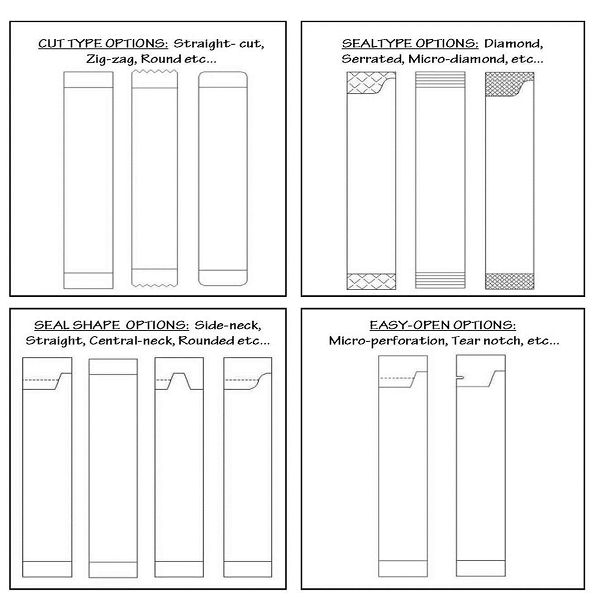

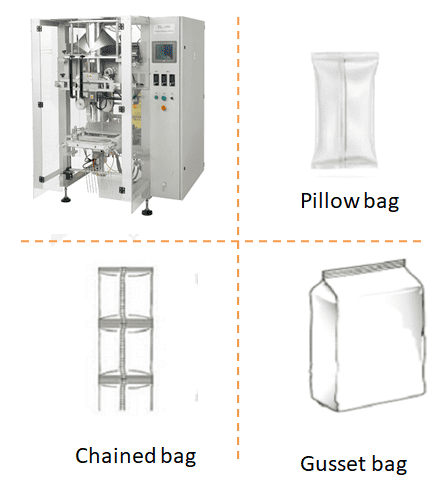

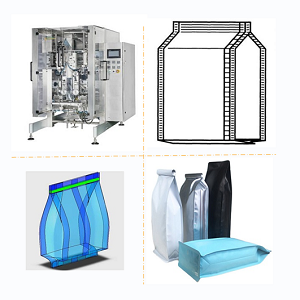

In the ever-evolving landscape of packaging solutions, the tea bag packing machine stands out as a hallmark of innovation and efficiency. As we approach 2025, advancements in technology have enabled manufacturers to create machines that not only streamline production but also enhance product quality. With a focus on automation, these machines now offer features such as adjustable fill weights and customizable bag sizes, catering to the diverse demands of global markets. The price of tea bag packing machines varies based on features and capabilities, but the investment becomes worthwhile when considering the long-term benefits it brings to production efficiency and product consistency. Investing in a state-of-the-art packing machine can significantly reduce labor costs and increase output, all while maintaining high standards of hygiene and precision. For businesses looking to scale operations, understanding the value and innovation embedded in these machines is crucial. As procurement managers seek reliable solutions that marry quality with affordability, exploring options that leverage cutting-edge technology and sustainable practices will undoubtedly yield the best results. The integration of smart features such as predictive maintenance and real-time monitoring ensures that businesses remain competitive in an increasingly demanding marketplace. Embracing the future of tea bag packaging not only guarantees operational excellence but also aligns with consumer trends towards sustainability, positioning companies for success in the global arena.

Tea Bag Packing Machine Price Products Where Innovation Meets 2025

| Model | Capacity (Bags/Hour) | Features | Technology | Dimensions (mm) |

|---|---|---|---|---|

| TBM-300 | 300 | Automatic Bagging, User-Friendly Interface | Servo Motor Technology | 1500 x 800 x 1800 |

| TBM-500 | 500 | Multi-Language Touchscreen, Quick Changeover | PLC Control System | 1800 x 900 x 1900 |

| TBM-700 | 700 | High Efficiency, Integrated Printing Function | AI Optimization | 2000 x 1000 x 2000 |

Related Products