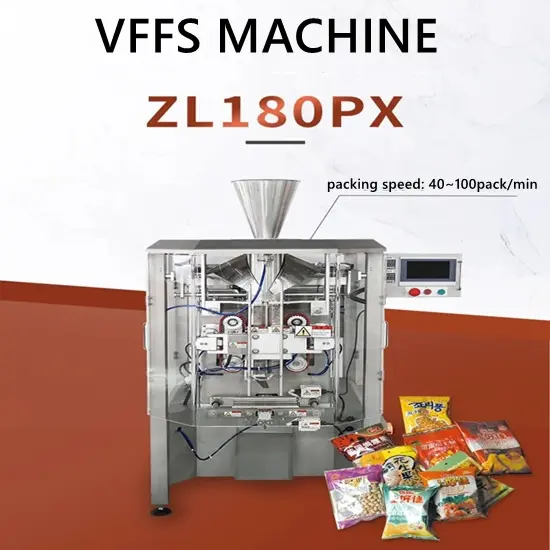

An automated packaging system is a crucial investment for any growing snack food business. The global snack food market is projected to grow to $248.77 billion in 2025, showing significant opportunity. For startups, a Vertical Form Fill Seal (VFFS) machine offers the ideal balance of cost, speed, and efficiency. This Chips Packing Machine creates, fills, and seals bags from a single film roll. Selecting the right VFFS machine requires evaluating its speed, flexibility, cost, and the supplier's reliability to ensure a successful investment.

Why a VFFS Machine is the Top Choice for Startups

Startups need packaging solutions that are efficient, scalable, and cost-effective. A Vertical Form Fill Seal (VFFS) machine meets these needs perfectly. It integrates multiple processes into one automated system, reducing labor costs and improving productivity. Operators use intuitive touchscreen interfaces to control the entire line. This simplifies adjustments for pouch dimensions and weight, streamlining the entire operation from start to finish.

How a VFFS Machine Works

Understanding the VFFS process reveals its efficiency. The machine automates bag creation, filling, and sealing in a continuous vertical motion.

1.Bag Forming: A roll of packaging film is fed over a cone-shaped forming tube. This tube shapes the flat film into a bag and creates the vertical seam.

2.Product Filling: The machine is electronically synchronized with a filler, like a multi-head weigher. The weigher accurately doses and drops the chips into the partially formed bag.

3.Sealing and Finishing: Once filled, a set of heated jaws seals the top of the bag. This same action creates the bottom seal for the next bag. A knife then cuts the completed bag free, which is then collected for shipment.

VFFS vs. Premade Pouch Machines

Businesses often choose between VFFS machines and premade pouch machines. While premade pouch machines are fast, VFFS systems offer distinct advantages for startups focused on efficiency and cost control. A VFFS Chips Packing Machine forms bags from rollstock film, which significantly reduces material waste and lowers the cost per bag.

| Feature | VFFS Machine | Premade Pouch Machine |

|---|---|---|

| Material Cost | Lower (uses rollstock) | Higher (uses premade bags) |

| Material Waste | Minimal | Moderate |

| Flexibility | High (easy size changes) | Limited to pouch inventory |

Pro Tip: For high-volume production with one or two product lines, VFFS machines deliver sleek, professional bags for a lower cost per impression than premade pouches.

Balancing Cost and Production Speed

The initial investment in a VFFS machine delivers a strong return through enhanced speed and quality control. High-speed models from brands like Soonture can produce over 80 packages per minute. This level of output helps businesses meet growing demand and expand their market reach. The long-term value comes from improved filling accuracy, reduced material costs, and lower labor requirements, making it a strategic investment for any growing snack brand.

Key Components of a Chips Packing Machine

Understanding the core components of a VFFS machine helps businesses make an informed purchasing decision. Three parts are critical for the performance of any Chips Packing Machine: the weigher, the film system, and the sealing jaws. Each component plays a distinct role in creating a perfect bag of chips.

The Multi-Head Weigher

The multi-head weigher is the brain of the weighing operation, ensuring each bag meets its target weight. It uses a computerized system to calculate the best combination of weights from multiple small hoppers. This intelligent algorithm achieves incredible precision, dramatically reducing product giveaway compared to older technologies.

| Feature | Linear Weigher | Multi-Head Weigher |

|---|---|---|

| Accuracy | ±1 g to ±5 g | ±0.5 g to ±2 g |

This precision minimizes overfilling, saving money on every bag produced. For a startup, reducing product giveaway from 7% to under 1.5% translates directly to higher profit margins.

The Film Roll and Former

The journey of the bag begins at the film roll and forming tube. The machine pulls a flat sheet of packaging film from a large roll. This film then travels over a forming tube, which shapes the material into a vertical cylinder. The choice of film material is crucial for product protection and branding.

·Monolayer Films: Economical and clear, ideal for snacks where a basic barrier is sufficient.

·Multilayer Films: Offer superior protection against moisture and oxygen, preserving chip freshness.

·Specialty Films: Include recyclable or bio-based options for brands focused on sustainability.

The Sealing Jaws

Sealing jaws create the airtight seals that keep chips fresh and crunchy. The process involves two key actions. First, a vertical sealing bar presses the overlapping edges of the film together to create the back seal. Next, a pair of heated horizontal jaws clamps down. This single motion accomplishes three tasks: it forms the top seal of the filled bag, creates the bottom seal for the next bag, and cuts the finished bag free. This efficient system ensures a strong, hermetic seal every time.

Must-Have Features for Your First Machine

Selecting the right VFFS machine involves more than just its core components. Certain features directly impact daily operations, profitability, and the ability to scale. Businesses should prioritize speed, flexibility, and user-friendliness when evaluating potential models.

Speed and Output (Bags Per Minute)

Production speed, measured in Bags Per Minute (BPM), is a primary indicator of a machine's efficiency. For a startup, a machine with a speed of 40-60 BPM is often an excellent starting point. This rate allows a business to meet initial demand while leaving room for growth. However, the maximum achievable speed is not a fixed number; it depends heavily on the bag's dimensions.

Bag width directly influences the speed of a Chips Packing Machine. A wider bag accommodates a larger diameter forming tube, which allows the product to fill more quickly. For instance, filling a 115mm wide bag is faster than filling a 90mm wide bag with the same weight of chips because the larger opening requires fewer actions from the weigher. Additionally, sufficient head space—the empty area between the product and the top seal—is vital. It gives the chips time to settle, preventing them from getting caught in the sealing jaws and causing a machine stoppage.

Note: When choosing a machine, a business should consider both its current production needs and its future growth targets. A machine that can scale in speed offers better long-term value.

Flexibility and Changeover

Market demands change. A successful snack brand may need to introduce new bag sizes, run promotional packaging, or switch film materials. The ability to adapt quickly with minimal downtime is known as changeover flexibility. A machine designed for rapid changeover is a significant asset.

Modern VFFS baggers are engineered for this versatility. Key features that reduce changeover time from hours to minutes include:

·Quick-Change Forming Tube Assemblies: These allow operators to swap out the component that shapes the bag without needing extensive tools or recalibration.

·Program/Job Storage: Modern machines can store dozens of unique production recipes. An operator can recall settings for a specific bag size, film type, and product weight with a single touch, eliminating manual adjustments.

This level of flexibility allows a company to pivot quickly, maximizing uptime and ensuring the packaging line remains a profitable part of the operation.

Ease of Use and Maintenance

A powerful machine is only effective if the team can operate and maintain it properly. An intuitive design and straightforward maintenance procedures are essential for maximizing uptime and ensuring a long service life.

A user-friendly Human-Machine Interface (HMI) simplifies operation. Instead of complex controls, modern machines feature a large color touchscreen that provides access to all functions. Key HMI features to look for include:

·Intuitive Controls: Simple menus for setting bag length, sealing temperature, and production counts.

·On-the-Fly Adjustments: The ability to fine-tune parameters while the machine is running.

·Production Statistics: Real-time data on output, efficiency, and downtime.

·Diagnostic Assistance: On-screen troubleshooting guides to help operators resolve minor issues quickly.

Equally important is a clear maintenance plan. Regular upkeep prevents unexpected breakdowns. A good supplier provides a detailed schedule for routine tasks.

| Maintenance Frequency | Key Tasks |

|---|---|

| Daily | Clean & Inspect: Wipe down sensors and touchscreens. Remove debris from sealing jaws and hoppers. Visually inspect for loose parts or damage. |

| Weekly | Deep Clean & Lubricate: Disassemble accessible parts for thorough cleaning. Lubricate moving components like bearings and chains per the manual. Tighten any loose fasteners. |

Following a consistent maintenance routine ensures the machine runs smoothly, produces high-quality bags, and delivers a strong return on investment for years to come.

Machine Footprint and Layout

Physical space is a valuable resource for any growing business. The machine's footprint—the amount of floor space it occupies—is a critical factor in the purchasing decision. Businesses must evaluate not only the dimensions of the machine itself but also the surrounding area required for efficient operation, maintenance, and material flow. A well-planned layout prevents bottlenecks and ensures a safe working environment.

The VFFS machine is the centerpiece of the packaging line, but it does not operate in isolation. An entry-level system has significant physical dimensions. The table below provides a typical example of the size and weight of a complete VFFS system, including the multi-head weigher.

| Category | Value (mm) | Value (in) |

|---|---|---|

| Machine Height | 2065 | 82 |

| Machine Width | 1180 | 46.5 |

| Machine Length | 2229 | 88 |

| Shipping Weight | 1100 kg | 2425 lbs |

These measurements highlight the need for careful planning. Beyond the machine's direct footprint, a successful layout must account for several other factors:

·Infeed and Outfeed Conveyors: Space is necessary for conveyors that bring product to the weigher and transport finished bags away for case packing.

·Operator Workspace: Operators need adequate room to move around the machine safely, access the HMI, and monitor production. A minimum of 3 feet (approximately 1 meter) of clearance on all sides is a standard recommendation.

·Material Staging: A designated area is required for storing rolls of film and other packaging materials near the machine for quick changeovers.

·Maintenance Access: Technicians need unobstructed access to all sides of the machine, including the rear and top, for cleaning, repairs, and preventative maintenance.

Pro Tip: Always design the production layout with future growth in mind. Allocating extra space from the beginning makes it easier to add a second packaging line or supplementary equipment like checkweighers and metal detectors later without a major facility overhaul.

Vertical space is just as important as floor space. The multi-head weigher sits on top of the VFFS bagger, making the total height of the system a primary concern. Facilities must have sufficient ceiling clearance to accommodate the full height of the Chips Packing Machine and allow operators to safely access the weigher for cleaning and service.

Understanding the True Cost of Your Investment

A VFFS machine is a significant capital expenditure. A business must look beyond the sticker price to understand the total financial commitment and potential returns. Evaluating the initial cost, return on investment, and ancillary expenses provides a complete picture of the investment's true value.

Entry-Level VFFS Machine Prices

For startups and small businesses, an entry-level VFFS system is an accessible starting point. The price for a complete system, including a multi-head weigher and the bagger, typically ranges from $25,000 to $50,000. This price point provides a reliable, automated solution capable of meeting initial production demands. Factors like brand reputation, included features, and the level of customization will influence the final cost within this range.

Calculating Your Return on Investment

Return on Investment (ROI) measures the profitability of the machine. It shows how quickly the investment will pay for itself through increased efficiency and cost savings. Businesses calculate ROI by comparing the net profit gained from the machine to its total cost. Key factors that accelerate ROI include higher production output, reduced labor costs, and minimized product giveaway from the precision weigher.

A strong ROI is achieved when the machine's efficiency gains and cost savings quickly surpass its total purchase and operational costs.

Budgeting for Hidden Costs

The initial purchase price is only one part of the total investment. Smart businesses budget for additional expenses to avoid financial surprises and ensure a smooth implementation. These costs are part of the Total Cost of Ownership (TCO) and are essential for getting the machine operational.

Common costs to include in the budget are:

·Shipping: Transporting the heavy equipment from the manufacturer to the facility.

·Installation and Commissioning: Fees for professional technicians to set up, calibrate, and test the machine.

·Training: Costs for training operators and maintenance staff to use and care for the new equipment effectively.

Planning for these expenses ensures the project stays on budget from delivery to the first production run.

How to Evaluate and Choose a Supplier

Choosing a supplier is as important as choosing the machine itself. A great supplier acts as a long-term partner, providing support that ensures the equipment remains a productive asset for years. Businesses should evaluate potential suppliers on their ability to deliver comprehensive service beyond the initial sale.

Key Supplier Evaluation Criteria

A reliable supplier offers more than just a machine; they provide a complete support system. This partnership is crucial for maintaining operational continuity and maximizing the machine's lifespan. Key evaluation criteria include:

·After-Sales Support: The supplier must offer robust maintenance services, readily available spare parts, and responsive technical assistance to minimize downtime.

·Lifecycle Services: Look for comprehensive programs that include operator e-training, spare parts subscriptions, and potential machine upgrades to adapt to future needs.

·Technical Assistance: A strong partner provides in-depth staff training and troubleshooting support. They should offer both remote and on-site assistance for resolving urgent issues quickly.

Questions to Ask Potential Suppliers

A business should prepare a list of specific questions to vet potential partners thoroughly. Clear answers to these questions will reveal a supplier's commitment to customer success.

Key Questions for Suppliers:

1.What is your standard response time for a service request?

2.Do you stock critical spare parts locally for fast delivery?

3.What does your standard training program cover, and is on-site training included?

4.Can you provide references from other customers in the snack food industry?

Importance of CE and UL Certifications

Safety and compliance are non-negotiable. Certifications like CE and UL are official declarations that a machine meets rigorous safety and quality standards.

The UL mark is vital for the North American market. It confirms the equipment adheres to safety standards recognized by regulatory bodies like OSHA. Reputable manufacturers invest in UL certification to demonstrate their commitment to operator safety and product reliability.

The CE mark is a mandatory requirement for machinery sold within the European Union. It signifies that the equipment complies with EU directives for health, safety, and environmental protection. For a business with global ambitions, these certifications are essential for market access and building customer confidence. They assure everyone that the equipment is well-designed, safe to operate, and built to last.

Top Brands and Models to Consider for 2025

Navigating the market for a VFFS machine can be complex. The industry offers a wide spectrum of options, from basic models for startups to highly advanced systems for large-scale operations. Understanding the key players in each category helps a business align its choice with its budget, production goals, and long-term vision. This guide breaks down the top brands into three distinct tiers: entry-level, mid-range, and high-end.

Entry-Level Options (e.g., SpackMachine, Landpack)

Entry-level machines are the ideal starting point for small businesses and startups. These systems prioritize affordability and simplicity, providing a reliable path to automation without a massive capital investment. Brands like SpackMachine and Landpack are prominent in this space. They offer functional, no-frills machines that get the job done efficiently. These models are perfect for businesses transitioning from manual packaging or those with modest initial production targets.

A business can expect solid performance for standard packaging tasks. The focus is on core functionality rather than advanced features.

| Feature | Typical Entry-Level Offering | Best For |

|---|---|---|

| Speed | 20-50 BPM | Startups with low to moderate volume needs. |

| Cost | Most affordable price point. | Businesses with a tight initial budget. |

| Operation | Simple controls, basic HMI. | Operations with limited technical staff. |

| Flexibility | Manual or tool-assisted changeovers. | Companies with a few consistent bag sizes. |

These machines provide an excellent return on investment by automating a labor-intensive process, enabling a small brand to grow its output and enter new markets.

Mid-Range Solutions (e.g., Soonture, Viking Masek)

Mid-range solutions represent the sweet spot for many growing businesses. These machines offer a powerful blend of speed, reliability, and advanced features at a competitive price. Brands like Soonture and Viking Masek lead this category. They provide robust systems that can handle increased production demands while offering greater flexibility than entry-level models. A mid-range Chips Packing Machine is a strategic investment for companies planning to scale.

Soonture, for example, is known for delivering high-performance machines with modern features like intuitive touchscreen controls and quick-change formers. Viking Masek has built a strong reputation for durable and dependable equipment.

Key advantages of investing in a mid-range system include:

- Enhanced Speed: Production rates often range from 50 to 90 BPM, enabling businesses to meet rising consumer demand.

- Greater Flexibility: These machines typically feature program storage and faster changeover capabilities, reducing downtime between different product runs.

- Improved Durability: They are built with higher-grade components designed for more continuous operation.

- Advanced Technology: Many models incorporate servo-driven components for more precise control over film pulling and sealing.

This category offers the best long-term value for businesses that have established their product line and are ready for significant growth.

High-End Systems (e.g., Matrix, Triangle)

High-end systems are engineered for large-scale, demanding production environments where speed, precision, and uptime are paramount. Brands like Matrix and Triangle are industry leaders, offering state-of-the-art machines with cutting-edge technology. These systems are designed for 24/7 operation and integrate seamlessly into fully automated packaging lines.

Matrix offers innovative, intelligent VFFS systems built for medium-to-high speed production. The Matrix Mercury model is a high-speed workhorse designed for longevity, achieving cycle speeds up to 140 BPM. For even more demanding requirements, the Matrix MVC (Morpheus) Series can reach speeds up to 200 ppm. These machines are built for packaging food products that may require longer seal times and can produce standard pillow, gusseted, and flat-bottom bags. Key features include:

·Flexible, tool-less changeovers for maximum uptime.

·Precise film control for consistent bag quality.

·Intuitive touch screens for simplified operation.

·The Morpheus AB model even includes advanced Rockwell controls.

Similarly, Triangle's machines stand out with features like an innovative mechatronic drive system, which enhances performance and reliability.

These high-end systems represent a significant investment. They are best suited for established enterprises with high-volume contracts that require maximum manufacturing and production efficiency. The technology inside, such as the continuous-motion, high-speed jaw system on the Matrix Morpheus, justifies the cost through unparalleled output and reliability.

Choosing a system from this tier means investing in top-tier performance and a partnership with a manufacturer at the forefront of packaging innovation.

A VFFS machine is a strategic investment for growing snack businesses, offering efficiency and scalability. For instance, Darlington Snacks doubled its production output by adopting this technology. A final decision must balance machine speed and features against the total budget and the supplier's support. Businesses should use this guide as a checklist to define their requirements—from production volume and material compatibility to after-sales service—before requesting quotes from suppliers.

FAQ

What film materials work with a VFFS machine?

VFFS machines handle various heat-sealable films. Common materials include polyethylene (PE), polypropylene (PP), and multi-layer laminated films for enhanced barrier protection. A business should always confirm film compatibility with its machine supplier to ensure optimal performance and seal quality.

How much training is needed to operate a VFFS machine?

Modern machines feature intuitive touchscreen interfaces (HMIs) that simplify operation. Suppliers typically provide comprehensive training during installation. An operator can learn basic functions and daily tasks within a few days, enabling them to manage production efficiently with minimal supervision.

Can one machine pack different bag sizes?

Yes. Businesses can pack multiple bag sizes on a single machine by swapping out the forming tube assembly. This component shapes the bag's width. Many modern systems, like those from Soonture, offer quick-change designs that minimize downtime and maximize production flexibility.

What is the typical lead time for a new machine?

The lead time for a new VFFS machine generally ranges from 6 to 12 weeks. This timeframe can vary based on the manufacturer's production schedule and the level of customization required for the system. A business should request a specific delivery timeline from its chosen supplier.

Post time: Dec-05-2025