A high-speed grain bagging system represents a strategic investment when an operation’s scale and storage bottlenecks justify the capital outlay. Large-scale farms often realize major efficiency gains, but smaller operations may find the initial costs prohibitive. The growing demand for flexible storage solutions is driving significant market expansion.

Market Insight: The grain and silage bags market is projected to grow at a 6.5% CAGR, expanding from an estimated USD 1.2 billion in 2024 to USD 1.9 billion by 2033.

This analysis weighs the financial benefits of these Food Grain Packing Machines against their costs to determine if it is the right move for your facility in 2026.

What Are the Financial Benefits of High-Speed Bagging?

Investing in high-speed Food Grain Packing Machines unlocks several powerful financial advantages for large-scale agricultural operations. These benefits extend beyond simple storage, impacting harvest efficiency, labor budgets, and overall profitability. A modern system, engineered for precision and speed, can fundamentally change an operation's financial outlook during its most critical season.

Drastically Increase Harvest Throughput

Harvest throughput measures the volume of grain an operation can move from the field to storage in a given period. High-speed bagging systems directly accelerate this process. Combines can run continuously without waiting for trucks to return from distant elevators or for on-site bins to clear. This uninterrupted workflow is the key to maximizing daily harvest capacity.

Operational Advantage: A continuous bagging process creates a mobile, high-capacity receiving point directly in or near the field. This eliminates the most common bottleneck in the harvest logistical chain: transport and unloading delays.

Modern systems achieve this remarkable speed through advanced engineering. Many utilize a uniaxial or biaxial servo control system, which provides precise control over the film pulling structure. This technology ensures the bag is filled evenly and rapidly, allowing the bagger to keep pace with multiple combines working at full capacity. The result is more bushels harvested per hour, reducing the overall time the crop remains vulnerable to adverse weather in the field.

Reduce Seasonal Labor Costs

The harvest season often requires hiring a significant amount of temporary labor, which introduces costs related to wages, training, and management. High-speed bagging streamlines the harvest workforce and delivers substantial savings. The automation inherent in these systems reduces the dependency on a large team.

An efficient bagging operation typically requires:

·A skilled operator for the bagging machine.

·A tractor operator to manage the bagger.

·A grain cart operator to ferry grain from the combines.

This lean team can replace a much larger crew that would otherwise be needed for trucking grain off-site or managing a complex on-farm bin system. By minimizing the number of seasonal hires, an operation reduces its direct payroll expenses and the associated administrative burden.

Lower Per-Bushel Storage Costs

One of the most compelling financial arguments for grain bagging is its impact on storage costs. Building permanent steel bins represents a massive capital expenditure. Grain bagging systems provide the same storage capacity with a significantly lower upfront investment. These Food Grain Packing Machines offer a cost-efficient solution, often costing half or even two-thirds less than traditional metal bins.

This lower initial cost barrier allows farms to scale their storage capacity in direct response to yield, rather than being constrained by fixed infrastructure. A direct comparison of the capital costs associated with each storage type clearly illustrates this financial advantage.

| Storage Type | Cost per Ton of Storage Capacity |

|---|---|

| Bag Silos | $1 to $3 |

| Steel Silos | $25 to $45 |

Note: Costs are estimates and can vary by region and supplier.

This dramatic difference means capital is not tied up in fixed assets. Instead, it can be allocated to other revenue-generating areas of the operation. The lower per-bushel cost of storage directly improves the farm's bottom line and financial flexibility.

Improve Marketing Flexibility and ROI

Perhaps the most significant financial benefit of high-speed grain bagging is the power it gives an operation over its marketing strategy. Traditionally, farmers are price takers at harvest. They must sell their grain immediately when market supply is at its peak and prices are consequently at their lowest. This pressure comes from a lack of on-farm storage or the need to free up capital. High-speed bagging fundamentally severs the link between harvesting and selling, transforming a producer's financial position.

By creating secure, on-farm storage, operators can hold their inventory and wait for more favorable market conditions. This extended marketing window allows them to capitalize on post-harvest price rallies.

Market Arbitrage in ActionStoring grain allows producers to benefit from seasonal price increases. For example, historical data from markets like Memphis, Tennessee, shows that corn prices in the spring can climb as much as 70 cents per bushel higher than the lows seen during the fall harvest.

This strategy directly enhances profitability. Studies on hermetic storage bags show that holding grain for several months can result in substantially higher selling prices. One analysis found that producers achieved a 38% higher price by storing grain for over nine months post-harvest. This premium is driven by two factors:

1.Reduced Market Supply: Selling during the off-season when grain is scarcer naturally commands a better price.

2.Superior Grain Quality: The controlled environment inside the bag preserves grain quality, which is a feature buyers will pay more for.

This ability to time the market turns a potential loss into a significant gain. The additional revenue generated by capturing a higher price per bushel, multiplied across an entire harvest, provides a clear and rapid Return on Investment (ROI) for the initial purchase of the Food Grain Packing Machines. It empowers the operation to move from a reactive seller to a strategic market participant, maximizing the value of every bushel harvested. These Food Grain Packing Machines are not just for storage; they are a powerful tool for financial management.

What Are the Operational Advantages?

Beyond the clear financial returns, high-speed grain bagging delivers significant operational improvements that streamline harvest logistics and protect crop value. These systems enhance an operation's resilience and efficiency during its most demanding period. The advantages range from superior grain preservation to unmatched logistical flexibility, fundamentally changing how a farm manages its harvest workflow.

Enhance Grain Quality and Preservation

Properly sealed grain bags create a hermetic, or airtight, environment that is ideal for long-term grain preservation. The natural respiration of the grain and microorganisms consumes the available oxygen. This process generates carbon dioxide, creating an anaerobic atmosphere inside the bag.

“If these bags are sealed properly, oxygen cannot get in or out. This creates an anaerobic environment that suffocates grain-damaging insects and prevents fungi from growing.”

— Hugo De Groote, CIMMYT Economist

This oxygen-depleted environment effectively halts the lifecycle of pests and inhibits the growth of harmful fungi like Fusaria. As a result, the risk of mycotoxin development is significantly reduced. Studies show that maintaining grain moisture content below 14% within these sealed bags is key. Effective hermetic bags can preserve this optimal moisture level for over 12 months, ensuring higher germination rates and protecting the grain’s commercial value.

Gain Unmatched Storage Scalability

Grain bagging offers unparalleled flexibility for storage capacity. Unlike permanent steel bins, which represent a fixed and costly infrastructure investment, bagging allows an operation to scale its storage precisely to that year's yield. A farm can add more bags during a bumper crop year or use fewer in a season with lower yields. This "pay-as-you-go" model provides a dynamic solution that adapts to the unpredictable nature of agriculture. An operation is no longer constrained by its existing bin capacity, giving it the freedom to store 100% of its harvest on-site every year.

Reduce Harvest Bottlenecks

One of the most immediate operational benefits is the elimination of harvest bottlenecks. In traditional systems, combines often sit idle, waiting for trucks to return from distant elevators or for on-farm augers to clear. High-speed Food Grain Packing Machines create a continuous, high-capacity receiving point directly in or near the field. Grain carts can unload directly into the bagger, allowing combines to keep running without interruption. This seamless workflow maximizes the productivity of every machine and operator, accelerating the entire harvest process and reducing the crop's exposure to weather risks.

Comparing Food Grain Packing Machines

When evaluating high-speed bagging systems, operators will find that not all Food Grain Packing Machines are created equal. Modern systems offer a range of advanced features and configurations designed to meet diverse operational needs. Understanding these differences is crucial for selecting a machine that delivers maximum efficiency and reliability.

Key technological differentiators include:

·Drive and Control Systems: Top-tier machines utilize a uniaxial or biaxial servo control system. This technology provides exceptionally precise control over the film pulling process, ensuring consistent bag length and rapid filling. Some models also offer a vacuum adsorption pull film system, which is ideal for handling specific or delicate packing materials.

·Sealing Mechanism: The horizontal sealing system is another critical component. Operations can choose between a pneumatic drive system, known for its reliability, or a servo drive system, which offers greater speed and precision. This choice allows a facility to match the machine’s capabilities to its specific throughput and budget requirements.

·Packaging Versatility: Advanced systems are not limited to a single bag type. They can produce various packing formats to suit different storage or market needs. Common options include the standard pillow bag, side ironing bags, gusset bags for better stacking, and even continuous bag types.

·Measurement Integration: For ultimate accuracy, these machines combine seamlessly with sophisticated measuring equipment. They can integrate with a multi-head weigher, an auger scale, or a volume cup system to ensure each bag is filled to the precise target weight.

Note on Quality Standards: The design of a superior machine conforms to Good Manufacturing Practice (GMP) standards and has passed CE certification. This signals a commitment to quality, safety, and operational excellence, ensuring the equipment is built for demanding agricultural environments.

What Are the Financial Drawbacks and Hidden Costs?

While high-speed grain bagging offers compelling advantages, a responsible analysis must also examine the significant financial commitments and ongoing expenses. Operations must weigh these costs carefully against the potential benefits. The financial hurdles range from the initial purchase price to the long-term costs of supplies, maintenance, and labor, all of which contribute to the system's total cost of ownership.

The Substantial Upfront Capital Investment

The most significant barrier to adopting a high-speed bagging system is the initial capital required. A new, high-capacity grain bagger is a major piece of agricultural machinery with a price tag that can be prohibitive for small to mid-sized operations. This investment often includes not only the bagger itself but also a compatible unloader, which is necessary to empty the bags for transport or sale.

Fortunately, financing options exist to make this investment more manageable. Producers can explore both government-backed programs and private lenders.

Financing Tip: The USDA's Farm Service Agency (FSA) offers a program designed specifically for this type of purchase.

The Farm Storage Facility Loan (FSFL) Program provides low-interest financing for on-farm storage equipment, including baggers. Key features of this program often include:

·Loan Amounts: Up to $500,000 with a 15% down payment.

·Microloan Option: A smaller loan up to $50,000 with only a 5% down payment and reduced paperwork.

·Favorable Interest Rates: Rates are fixed and typically lower than commercial alternatives. For example, past rates have been as low as 2.625% for terms up to 12 years.

·Application Fee: A nonrefundable $100 fee is required.

Beyond government programs, equipment dealers offer commercial financing. These options might include no-interest periods for short-term loans or fixed-rate financing over several years, though rates are generally higher than FSA loans and depend on credit approval.

Recurring Costs of Bags and Maintenance

The initial purchase is only the beginning of the financial commitment. An operation must budget for significant recurring costs to keep the system running efficiently.

First, the plastic grain bags are a primary consumable expense. An operation will need to purchase a new set of bags for every harvest. The total annual cost depends directly on the volume of grain stored. A farm with a bumper crop will face a proportionally higher bag cost.

Second, maintenance is a critical and unavoidable expense. Like any piece of heavy machinery, a grain bagger requires regular service to prevent costly downtime during the critical harvest window. Annual parts replacement alone can average between 5% and 7% of the machine's original purchase price. This figure does not include labor for repairs or routine preventative maintenance, which adds to the overall operational budget. Neglecting maintenance to save money in the short term almost always leads to greater expenses and lost productivity later.

The Total Cost of Ownership

To make a sound financial decision, an operation must look beyond the sticker price and calculate the Total Cost of Ownership (TCO). TCO provides a comprehensive view of all expenses incurred over the equipment's entire lifespan, from purchase to disposal. It is the most accurate measure of the system's true financial impact.

Calculating TCO is a detailed process that includes numerous variables. A thorough analysis should account for:

·Initial Investment: The cost of the bagger and unloader, minus any down payment.

·Financing Costs: The total interest paid over the life of the loan.

·Consumable Costs: The annual expense for grain bags, which fluctuates with yield.

·Operating Costs: Labor expenses for machine operators and the time spent starting each new bag.

·Maintenance and Repairs: Annual budget for parts, service, and unexpected repairs.

A crucial factor that reduces the TCO is the machine's resale value. A well-maintained bagger from a reputable brand will retain more of its value over time. Factors like hours of use, condition, and service history directly influence how much capital an operation can recover upon selling the equipment. A higher projected resale value effectively lowers the total cost of owning the machine. By forecasting these elements over a 10-year period, a producer can determine the true cost per bushel to use the system and make an informed comparison against other storage alternatives.

What Are the Operational Hurdles and Risks?

Adopting high-speed grain bagging technology introduces operational complexities that require careful management. While the benefits are significant, facilities must prepare for challenges related to labor, equipment reliability, and environmental responsibility. Proactive planning is essential to mitigate these risks and ensure a smooth, efficient harvest.

Dependence on Skilled Operators

A high-speed bagging system is only as effective as the person running it. These advanced machines demand operators with specific technical skills. Comprehensive training is not optional; it is necessary to prevent equipment damage, poor performance, and safety hazards. A skilled operator must master numerous procedures to maximize efficiency.

Key operational competencies include:

·Properly attaching and opening each new bag.

·Fine-tuning machine speed and output using the controls.

·Listening for unusual sounds or vibrations that signal a problem.

·Performing regular preventative maintenance, like cleaning and oiling key parts.

·Handling minor troubleshooting to prevent small issues from escalating.

Risk of Downtime from Equipment Failure

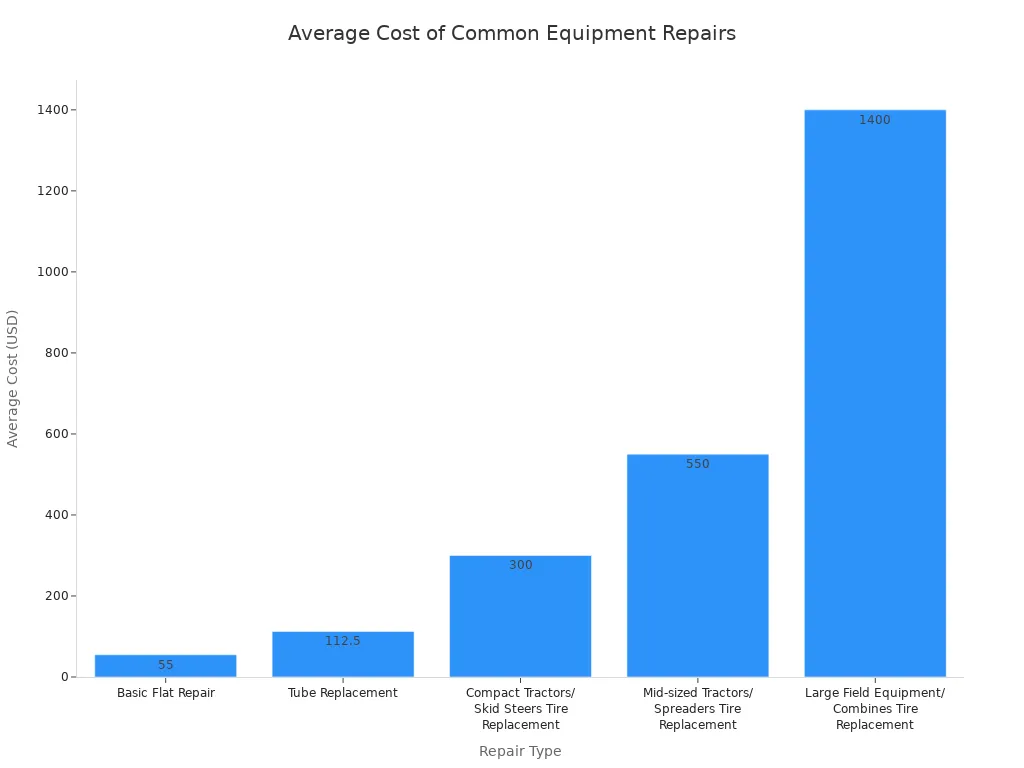

Any equipment failure during the critical harvest window can lead to costly delays. Repair downtime directly impacts profitability, with farmers experiencing an average annual loss of $3,348 from this issue alone. The costs can escalate quickly depending on the nature of the breakdown.

Equipment Repair Cost EstimatesRepair costs for agricultural machinery have nearly doubled over the past two decades. The expense varies significantly by the type of

Beyond direct repair costs, downtime creates cascading problems. It can lead to idle labor, missed operational deadlines, and significant transport fees if the machinery requires off-site service.

Environmental Impact of Plastic Bags

The use of large plastic bags raises valid environmental concerns. An operation must have a clear plan for disposing of or recycling the used bags after the grain is sold. Leaving them in fields creates waste and can harm the local ecosystem. Fortunately, robust recycling programs offer a sustainable solution.

A Model for Success: In Saskatchewan, Canada, a grain bag recycling program has proven highly effective. Farmers drop off used bags at collection sites. The plastic is then transported, shredded, washed, and extruded into pellets to manufacture new agricultural film products.

By participating in or advocating for similar programs, operations can turn a potential environmental liability into a responsible part of the circular economy.

Logistical and Safety Challenges

Effective grain bagging extends beyond the machinery itself; it requires meticulous site management to prevent logistical headaches and safety risks. The placement and preparation of the bagging site are critical first steps. A poorly chosen location can lead to bag damage, grain spoilage, and difficult extraction, undermining the system's benefits.

Proper site selection is the foundation of a successful bagging operation. Operators should choose a high, accessible area that allows water to drain away from the bags. If a perfectly level site is unavailable, bagging should always proceed downhill. The location should also be far from wooded areas or known wildlife paths to minimize animal interference.

Once a site is selected, preparation is key. Best practices include:

1.Clear the Ground: Remove all sticks, sharp rocks, and other debris that could puncture the bags.

2.Smooth the Surface: Knock down hard crop stubble from corn or beans by disking or rolling the ground firmly. This creates a smooth bed and prevents the bags from sinking.

3.Deter Pests: Apply a pest deterrent like ammonium nitrate or dry urea where the bags will lie. Animals dislike the ammonia scent. Never use sulfur, as it can degrade the plastic.

Proactive Management is EssentialOnce filled, bags require regular inspection. Operators should check them weekly for any rips or punctures from animals or weather. During periods of high rodent activity, daily checks may be necessary. Any damage must be patched immediately with high-quality tape or silicone to maintain the hermetic seal and prevent spoilage.

Mowing around the bags also helps keep weeds down. This simple step removes a food source that might attract animals, which could then chew on the bags. Careful planning and consistent oversight are essential to protect the stored grain and ensure a safe, efficient extraction process.

High-speed grain bagging offers compelling benefits in efficiency and flexible storage. It is a powerful tool for large-scale operations. However, significant hurdles like the high initial investment and technological dependency must be carefully weighed. The final decision hinges on an operation's specific scale and financial capacity.

Final Verdict: For the right operation, it is a strategic investment that enhances profitability. For others, the substantial costs will outweigh the potential returns, making traditional methods a more prudent choice.

FAQ

How long can grain be stored in these bags?

Properly sealed bags create an ideal hermetic environment. Operators can safely store grain with the correct moisture content for over 12 months. This extended period preserves grain quality, protects against pests, and allows for flexible marketing long after the harvest season ends.

What is the main difference between a bagger and a silo?

Grain bagging offers a mobile, scalable storage solution with a low initial investment. Steel silos are permanent, fixed-capacity structures requiring a much larger capital outlay. Bagging provides flexibility to match storage capacity directly to annual yield, avoiding the constraints of fixed infrastructure.

Are the plastic grain bags reusable?

No, the plastic bags are designed for single use only. The extraction process makes them unsuitable for refilling. Operations must have a plan for proper disposal. Many regions offer robust recycling programs that turn the used plastic into new agricultural products.

What other equipment is needed for a bagging system?

A complete system requires more than just the bagger. An operation also needs a grain cart to transfer grain from the combine to the bagger. Additionally, a specialized grain bag unloader is essential to efficiently extract the grain for transport or sale.

Post time: Dec-05-2025