A snacks packing machine performs several important tasks to prepare snacks for sale. First, it feeds snacks into a hopper or conveyor belt. Next, it measures the correct amount for each package. Then, it fills bags, pouches, or jars with the snacks. Finally, it seals each package tightly to keep the food fresh and safe for customers.

Snacks Packing Machine Operation

Product Feeding and Measuring

Snack packing machines begin their process with product feeding. Feeding equipment transports food materials to weighing devices. This step reduces manual contact and helps prevent contamination. Modern machines use advanced feeding technologies to improve efficiency and accuracy. Some of the most common methods include:

·Vibratory feeders that ensure even product distribution.

·Integrated conveyors that move snacks smoothly to the next stage.

·Weighers that measure precise portions for each package.

These key components work together to minimize the weight impact on the packaging machine. Soonture’s automated systems use these technologies to deliver consistent results and maintain high standards of food safety.

Filling and Packaging

After measuring, the machine fills the snacks into the chosen packaging. Different types of snack packing machines handle a variety of packaging methods, such as bags, wraps, and trays. The table below shows how packaging methods differ for popular snack types:

| Snack Type | Preferred Packaging Methods | Key Features |

|---|---|---|

| Chips and Puffed Snacks | Barrier plastic films with metal layers, nitrogen-flushed bags | Prevents staleness |

| Candy and Chocolate | Flow wrap plastic bags, paperboard trays, boxes, metal tins | Provides protection and freshness |

| Cookies and Biscuits | Wrapped in plastic film, foil and paperboard for bars | Maintains texture and quality |

| Nuts and Dried Fruits | Flexible pouches, vacuum or modified atmosphere packages | Ensures freshness and shelf life |

| Meat and Fish Snacks | High-barrier packaging, vacuum packs, retort pouches | Extends shelf life and maintains quality |

| Canned Snacks | Metal cans for nuts, premium biscuits, meat, fish | Offers extended shelf life and protection from damage |

Snack packing machines must adapt to different packaging lines and snack types. Soonture’s machines offer flexibility, allowing manufacturers to switch between packaging styles quickly. This flexibility is one of the most important features for companies that produce a wide range of snacks.

Sealing and Output

The sealing and output stage ensures that each package is secure and ready for distribution. The process includes several key steps:

1.Pouch loading

2.Pouch gripping

3.Printing or coding for traceability

4.Pouch opening and detection

5.Product filling

6.Product settling

7.Sealing and deflation

8.Cooling and discharge

Each step protects the food and maintains freshness. High-quality sealing prevents leaks and contamination. Machines like the RM-36 rotary filling machine can achieve high production rates, filling and sealing up to three containers per cycle. Vertical packing machines also deliver fast and efficient output, making them ideal for busy production environments.

The RM-36 achieves high production rates of 10 to 30 cycles per minute, with the ability to fill and seal up to three containers per cycle for higher throughput.

Manufacturers must consider how to choose the right snack packing machine for their needs. They should look at the types of snack packing machines available, the key components, and the features that matter most for their products. Soonture’s advanced automation and efficiency help companies meet high standards for food safety and packaging quality.

Key Features of Snack Packing Machines

Automation and Controls

Modern snack packing machines rely on automation to improve efficiency and reduce errors. These machines use advanced technologies to handle repetitive tasks and ensure consistent results. The table below shows some of the most important automation technologies and their benefits:

| Technology | Function & Advantage |

|---|---|

| Robotic Pick-and-Place | High-speed sorting and tray loading with vision guidance |

| AI-Based Quality Control | Defect detection using cameras and machine learning |

| IoT in Packaging Machines | Real-time monitoring, predictive maintenance, and traceability |

| Smart Labeling Systems | Dynamic label printing and data coding (QR, batch, expiry) |

| Sustainable Sealing Tech | Machines adapted to eco-materials like paper-based films |

Programmable logic controllers (PLCs) serve as key components in these systems. Operators use touchscreens to adjust pouch length, filling weight, temperature, and speed. PLCs also help with error diagnostics and real-time monitoring, making the snacks packing machine user-friendly and reliable. Soonture’s advanced features include custom PLCs and automation components that ensure high durability and performance.

Food Safety and Hygiene

Food safety remains a top priority in snack packing machines. Manufacturers design machines with food-grade stainless steel, which allows for easy cleaning and maintenance. Automatic cleaning functions help meet strict food safety standards. These designs reduce manual contact with food, lowering the risk of contamination. The table below lists important certifications for food safety:

| Certification | Description |

|---|---|

| SQF Certification | Assesses food safety and quality programs based on HACCP principles |

| GFSI-recognized schemes | Includes BRCGS, SQF, and FSSC 22000 for compliance in global markets |

Soonture’s machines meet these certifications, helping companies protect food quality and extend shelf life.

Speed and Accuracy

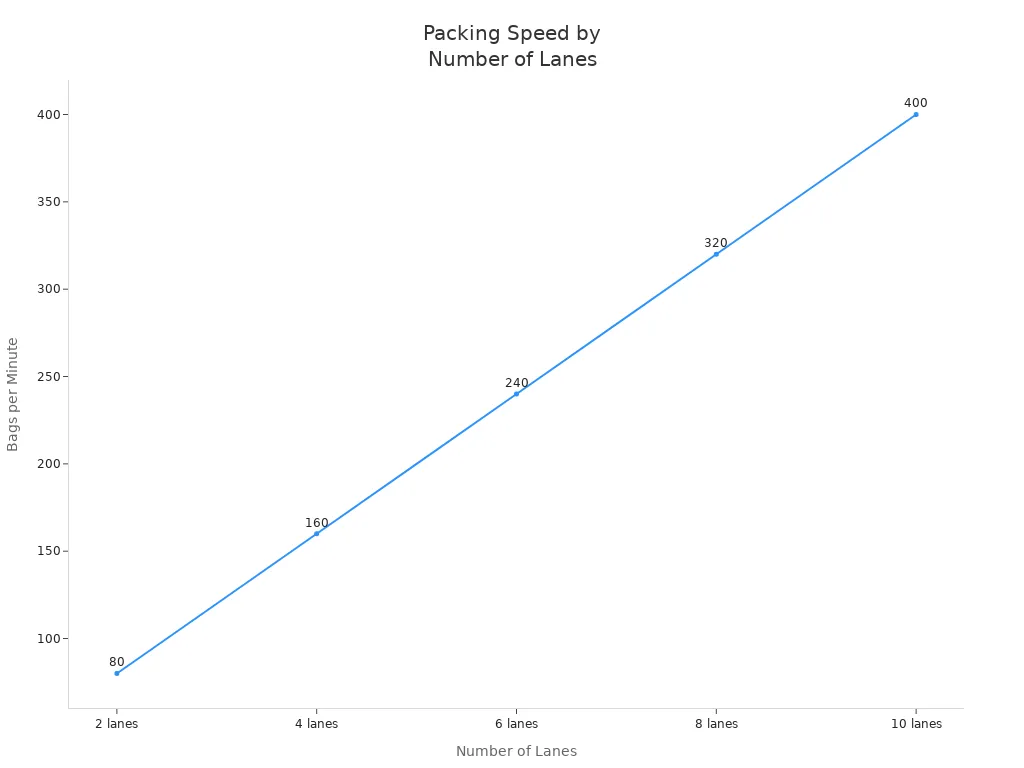

Snack packing machines must operate quickly and accurately to keep up with busy packaging lines. Automated flexible packaging machines can produce between 30 and 300 bags per minute. The chart below shows how packing speed increases with more lanes:

Multihead weighers use the combination weighing principle to achieve precise target weights. These systems maintain consistent pack weights, even when snack shapes or densities vary. Soonture’s machines use advanced control software to minimize material giveaway and ensure reliable portion control.

Flexibility for Snack Types

Snack packing machines must handle a wide range of snack products. Flexible designs allow machines to switch between different packaging formats and materials. Adjustable settings help operators tailor the filling range for various product sizes and volumes. Quick changeovers make it easy to adapt to new packaging lines or snack types. Soonture’s machines manage lightweight, fragile, and irregularly shaped snacks, ensuring consistent fill weights and reliable seals. These advanced features help manufacturers maintain food quality and extend shelf life across all types of snack packing machines.

Types of Snack Packing Machines

Snack packing machines come in several types, each designed for specific food products and packaging needs. Manufacturers select the right machine based on the snack’s texture, size, and packaging format. The main types include vertical form fill seal (VFFS) machines, multi-head weigher machines, and pouch and pick-fill-seal machines.

Vertical Form Fill Seal (VFFS)

VFFS machines automate the process of forming, filling, and sealing bags. These machines use rolls of film to create airtight pouches, which help preserve freshness and extend shelf life. Operators can choose from different bag styles, such as pillow packs, gusseted bags, and stand-up pouches. VFFS machines handle a wide range of snacks, including nuts, popcorn, candies, and cookies.

| Characteristic | Description |

|---|---|

| Automation | Forms, fills, and seals bags quickly and efficiently |

| Versatility | Adapts to various pouch sizes and snack types |

| Airtight Pouches | Maintains food freshness and quality |

| Bag Styles | Produces pillow, gusseted, and stand-up pouches |

| Product Range | Suitable for nuts, popcorn, candies, cookies, and powdery products |

Potato chips and extruded snacks benefit most from VFFS machines, especially when gas flushing is used to protect delicate items. These machines also support packaging for frozen foods, helping to keep products safe during storage and transport.

Multi-Head Weigher Machines

Multi-head weigher machines use advanced technology to weigh and fill snacks with high speed and accuracy. Each head weighs a portion of the product, and the machine combines these portions to reach the target weight. This process reduces manual labor and improves hygiene in food packaging lines.

·Automates weighing, lowering operating costs and increasing safety

·Ensures precise and consistent pack weights

·Increases throughput with simultaneous weighing

·Ideal for high-volume production environments

Nuts, candies, and other small food items are best suited for multi-head weigher machines. These machines help maintain product quality and extend shelf life by ensuring every pack contains the right amount of food.

Pouch and Pick-Fill-Seal Machines

Pouch and pick-fill-seal machines handle pre-formed pouches, making them versatile for many snack types. These machines automate filling and sealing, which improves efficiency and reduces labor costs. Operators can use these machines for snacks like banana chips, nachos, corn puffs, and fried lentils.

| Advantage | Description |

|---|---|

| Packaging versatility | Handles many products and pouch types |

| Efficiency and speed | Operates quickly, increasing production rates |

| Product quality | Ensures consistent, high-quality packaging |

| Cost-effectiveness | Reduces labor and material costs |

Manufacturers often use pouch and pick-fill-seal machines for commercial frozen food packaging machines, as well as for snacks that require zipper pouches, batch coding, or nitrogen flushing. These features help protect food and extend shelf life.

Tip: Choosing the right snacks packing machine depends on the snack’s texture, packaging needs, and production volume. For frozen food, commercial frozen food packaging machines provide the best results for maintaining quality and shelf life.

Other Packaging Lines and Accessories

Snack packing machines often work with other packaging lines, such as cartoning lines, packers, closers, and palletizers. Accessories like online check-weighers and color mark sensors help improve accuracy and traceability in food packaging.

Snack packing machines play a vital role in packaging lines by measuring, filling, and sealing food to protect quality and extend shelf life. Companies should focus on these factors when choosing a snacks packing machine:

1.Packing capacity and speed

2.Bag size and type

3.Machine durability and maintenance

4.Cost and ROI

5.Support and service

| Feature | Importance |

|---|---|

| Hygienic production processes | Reduces contamination risks and ensures compliance with food safety regulations. |

| Efficient operation | Maximizes production output and minimizes downtime. |

Advanced snack packing machines from Soonture help maintain food safety, boost efficiency, and improve packaging for many food products. These machines support longer shelf life and consistent packaging, making them a smart investment for any food business.

FAQ

How do snack packing machines help with food safety?

Snack packing machines use automated systems to reduce human contact with food. This process lowers the risk of contamination. Machines often include features like stainless steel surfaces and easy cleaning to support food safety.

What types of snacks can these machines package?

These machines can handle chips, nuts, candies, cookies, and dried fruits. Operators can adjust settings for different snack sizes and shapes. This flexibility helps maintain safety and quality for many food products.

Why is sealing important for food safety?

Sealing keeps air, moisture, and bacteria out of the package. This step protects food from spoilage and helps maintain freshness. Proper sealing supports both food safety and longer shelf life.

How do manufacturers ensure safety in snack packing machines?

Manufacturers use food-grade materials and design machines for easy cleaning. They follow strict safety standards and often get certifications. These steps help protect food and keep consumers safe.

Can snack packing machines improve efficiency?

Yes. Snack packing machines automate measuring, filling, and sealing. This automation increases speed and reduces errors. Companies can package more food in less time while maintaining high safety standards.

Post time: Nov-27-2025