Selecting the right plastic packing machine for food products requires careful evaluation of important factors to consider. Machine features must align with the type, texture, and packaging needs of each food item. The right choice can improve product quality, boost efficiency, and drive business growth. Recent industry trends show that responsible packaging increases consumer trust and preference for sustainable options. Companies should assess their production goals to match technology with market expectations and operational demands.

·Responsible packaging elevates product safety and quality perception

·Eco-labels influence buying decisions toward sustainable packaging

1.The food packaging market continues to expand, fueled by consumer demand for eco-friendly solutions.

2.Over half of buyers choose products with sustainable packaging.

Choosing Packaging Machinery for Food Products

Assess Product Characteristics

Choosing packaging machinery begins with a thorough evaluation of the food product’s unique attributes. Each product presents different requirements for size, shape, weight, and packaging materials. Manufacturers must consider these factors to ensure the selected machine delivers optimal performance and product safety.

| Characteristic | Description |

|---|---|

| Product attributes | Size, shape, weight, and required packaging materials are essential for selecting a suitable machine. |

| Production capabilities | Determine the required production capacity based on your production scale. |

| Degree of automation | Higher automation improves efficiency and reduces manual operations. |

| After-sales service | Choose manufacturers that provide comprehensive support for maintenance and service. |

| Efficient automated packaging | Machines should automate operations like unfolding, positioning, filling, and sealing. |

| Precise metering and filling | Ensures product quantities meet standards, reducing waste and enhancing precision. |

| High-quality sealing | Critical for maintaining product integrity and safety. |

| Flexible fit and appearance | Ability to adjust for different product packaging needs. |

| Fault detection and alarm | Continuous monitoring to detect faults and prevent downtime. |

Manufacturers should also consider the total cost of ownership. This includes the machine’s price, packaging film, labor, and maintenance. Higher automation often leads to long-term cost savings by reducing manual labor and minimizing errors.

Different food types influence the process of choosing packaging machinery. For example, delicate snacks require packaging that protects against physical impacts. Dried fruits and nuts need packaging that preserves freshness and prevents contamination. Chemical compatibility between the product and packaging material ensures safety and prevents spoilage. Sustainability has become a key factor, as consumers prefer recyclable and biodegradable options. Branding and visual appeal also play a role, as attractive packaging can influence purchasing decisions.

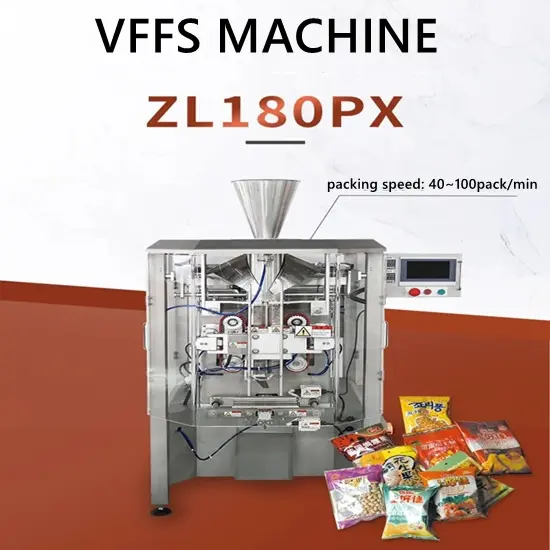

Soontrue’s VFFS Automatic Four Side Sealing Packing Machine stands out as a versatile solution for food manufacturers. This machine adapts to a wide range of product types, including granular, strip, sheet, block, ball-shaped, and powdered items. Its advanced servo control system allows precise adjustments for different packaging needs. The machine’s flexibility supports various bag sizes and formats, making it suitable for snacks, cashew nuts, popcorn, cookies, and more.

Tip: When choosing packaging machinery, prioritize adaptability. Machines that handle multiple product types and packaging formats provide greater value and future-proof your investment.

Match Packaging Formats and Materials

Matching packaging formats and materials to the product is a critical step in choosing packaging machinery. The right combination ensures product safety, compliance with food standards, and consumer satisfaction. Selecting the appropriate packaging material affects not only the appearance but also the durability and protection during storage and transport.

Common packaging materials include plastics, aluminum, paperboard, and glass. Each material offers unique benefits and trade-offs. For example:

·Plastics provide lightweight, flexible, and cost-effective solutions for many food products.

·Aluminum offers excellent barrier properties for moisture and light-sensitive items.

·Paperboard supports sustainability goals and enhances branding opportunities.

·Glass delivers premium appeal and strong protection but increases shipping costs.

Manufacturers must choose packaging materials based on protection, sustainability, branding, and compliance—not just cost. The selected material should help food stay fresh longer and ensure safe shipping. Sustainability continues to influence consumer preferences, with many buyers seeking recyclable or biodegradable packaging.

Soontrue’s VFFS Automatic Four Side Sealing Packing Machine demonstrates exceptional adaptability to different packaging formats. The machine supports pillow bags, side ironing bags, gusset bags, triangle bags, and continuous bag types. This flexibility allows manufacturers to respond quickly to market trends and customer demands. Integration with multi-head weighers, auger scales, and volume cup systems ensures accurate filling and efficient operation for a variety of products.

Choosing packaging machinery with high adaptability brings several advantages:

·Improved efficiency: Automated machines increase speed and output, helping manufacturers meet market demand.

·Enhanced consistency and quality: Uniform packaging reduces errors and maintains product standards.

·Better branding and consumer appeal: Flexible designs allow for attractive packaging that stands out on shelves.

When choosing packaging machinery, manufacturers should evaluate how well the equipment handles different packaging materials and formats. Machines like Soontrue’s VFFS model offer the versatility needed to support business growth and adapt to changing market requirements.

Plastic Packing Machine for Food Products: Speed and Efficiency

Evaluate Production Volume

Processing speed determines how quickly a plastic packing machine for food products can complete packaging tasks. Manufacturers should evaluate how many packages the machine can process per minute. High-speed machines increase output and help meet market demand during peak seasons. Automated systems, including vacuum packaging machine models, offer rapid sealing and filling for various packaging formats.

Key factors to consider when comparing speeds:

- Machine design and automation level

- Integration with weighing and dosing systems

- Ability to handle different packaging materials

Modern plastic packing machine for food products often feature servo control systems and touch screen interfaces. These technologies enable precise adjustments and quick changeovers, boosting overall packaging efficiency.

Minimize Downtime

Minimizing downtime ensures continuous operation and reduces production losses. Manufacturers can adopt several strategies to keep packaging lines running smoothly:

1.Implement proactive maintenance schedules. Regular inspections and timely replacement of worn-out parts prevent unexpected failures.

2.Prioritize hygienic design to prevent contamination. Clean equipment reduces the risk of product recalls and maintains food safety standards.

3.Evaluate and upgrade aging equipment. Newer models, such as advanced plastic packing machine for food products, offer easy maintenance access, allowing technicians to perform repairs quickly.

Modern automated packaging machines, including vacuum packaging machine options, maximize uptime with user-friendly maintenance features. These improvements help manufacturers maintain consistent packaging output and meet delivery deadlines.

Tip: Investing in reliable plastic packing machine for food products with advanced maintenance features supports long-term business growth and operational stability.

Cost and Investment in Food Packaging Machines

Initial vs. Long-Term Costs

Investing in food packaging machines requires careful analysis of both initial and long-term costs. Manufacturers often compare upfront expenses with ongoing operational savings. Blister packaging machines typically have higher initial costs, but they offer greater versatility and product protection. Strip packing machines present a more cost-effective solution for businesses focused on high-volume production. For low to medium production volumes, blister machines can become more economical over time due to lower per-unit costs. In high-volume scenarios, strip packing machines help reduce overall packaging costs significantly.

| Machine Type | Initial Cost | Long-Term Cost | Best Use Case |

|---|---|---|---|

| Blister | High | Lower/unit | Versatile, product protection |

| Strip | Lower | Lower overall | High-volume production |

Tip: Manufacturers should evaluate both immediate expenses and future savings when selecting food packaging machines.

Maintenance and Operating Expenses

Maintenance and operating expenses play a crucial role in determining the total cost of ownership for food packaging machines. Environmental factors such as dust, heat, and moisture can accelerate wear, increasing the need for routine care. Frequent use demands regular maintenance, which helps reduce costs and prevent breakdowns. Automated packaging systems require higher initial investment, but they deliver long-term benefits like reduced errors, time savings, and consistent quality. Automation can boost packaging speed by up to 50%, supporting business expansion and lowering unit costs. Annual maintenance costs vary based on production conditions and usage frequency. Preventive maintenance extends machine lifespan and minimizes repair expenses.

·Maintenance costs are essential for calculating total cost of ownership.

·Regular maintenance prevents breakdowns, reduces downtime, and improves safety.

·Efficient maintenance practices enhance consistency and productivity.

1.Reduced costs: Preventing breakdowns limits financial losses from production line downtime.

2.Increased consistency: Routine maintenance ensures compliance with packaging standards and reduces waste.

3.Extended lifespan: Proper care aligns machinery lifespan with expectations, lowering total cost of ownership.

Financing Options

Manufacturers have several financing options when investing in food packaging machines. Equipment loans and leasing provide flexible solutions for acquiring new machinery. SBA loans and vendor financing offer additional support for businesses seeking to expand their packaging capabilities. Alternative financing options, such as term loans, equipment financing, working capital loans, and lines of credit, help companies manage cash flow and invest in advanced technology. Government-backed loans and green loans support sustainability initiatives and ESG goals.

·Equipment loans

·Leasing

·SBA loans

·Vendor financing

·Term loans

·Working capital loans

·Lines of credit

·Government-backed loans

·Green loans and ESG financing

Note: Exploring multiple financing options enables manufacturers to choose the best strategy for their business needs.

Environmental Impact of Packaging Machinery

Energy Efficiency

Energy efficiency plays a vital role in modern packaging machinery. Manufacturers now use machines that consume less power, which helps lower operational costs. The Automatic Pouch Packing Machine stands out for its low power consumption and efficient operation. Many systems in the food and beverage sector use up to 50% less energy than older shrink systems. These advancements allow companies to save money and reduce their environmental footprint.

·Energy costs can reach 20% of total expenses in packaging production lines.

·Intelligent automation and high-efficiency motors help lower energy use.

·Shorter production cycles decrease energy per unit, leading to cost savings.

Servo drives and energy recovery features further reduce electricity usage. These technologies maintain production speed while reusing excess heat, which decreases overall energy demand.

Sustainable Materials

Packaging machinery supports the use of sustainable materials. Modern machines handle a wide range of biodegradable and recyclable options, such as cellulose, chitosan, starch, polylactic acid (PLA), and polyhydroxyalkanoates (PHA). These materials help companies meet sustainability goals and respond to consumer demand for eco-friendly packaging.

·Cellulose

·Chitosan

·Starch

·Polylactic Acid (PLA)

·Polyhydroxyalkanoates (PHA)

·Water-based polymer dispersions

·Plant-based coatings

Packaging machinery adapts to these materials, reducing reliance on single-use plastics and supporting innovations in sustainable solutions.

| Functionality | Description |

|---|---|

| Separation | Depacking machines separate organic food waste from packaging materials, aiding composting. |

| Contamination Reduction | Machines minimize contamination, ensuring cleaner recycling streams. |

| Compliance Support | Equipment helps meet waste regulations, facilitating recycling and composting. |

Waste Reduction

Waste reduction technologies in packaging machinery benefit both manufacturers and the environment. Machines use precision filling to minimize product spillage and smart material usage to decrease excess waste. Many systems support recyclable and eco-friendly packaging options.

| Feature | Benefit |

|---|---|

| Precision Filling | Reduces food waste during production. |

| Smart Material Usage | Uses only necessary material, lowering excess waste. |

| Recyclable Options | Supports sustainable practices with biodegradable and recyclable packaging. |

Waste reduction leads to lower greenhouse gas emissions, conserved resources, and reduced landfill use. These improvements protect biodiversity and enhance resource efficiency. Sustainable packaging technologies optimize design and material use, helping companies meet environmental goals while maintaining product protection.

Tip: Companies that invest in energy-efficient and sustainable packaging machinery gain a competitive edge and contribute to a healthier planet.

Flexibility and Adaptability in Food Packaging Machines

Multi-Product Capability

Modern food packaging machines must handle a variety of products to meet changing market demands. Manufacturers often process snacks, nuts, dried fruits, and powders on the same line. Machines with multi-product capability allow operators to switch between different items without major adjustments. This flexibility supports businesses that want to expand their product range or respond quickly to new trends. Operators can meet diverse requirements by using machines that accommodate granular, strip, sheet, block, and powdered products. This approach increases productivity and reduces the need for multiple machines.

Easy Changeover

Easy changeover features play a key role in operational efficiency. Operators can switch between products or packaging formats with minimal downtime. Companies that implement Single-Minute Exchange of Dies (SMED) principles often reduce changeover time by 50% or more. For example, a major beverage company cut cup size changeovers from 45 minutes to just 12 minutes by using pre-positioned tooling and standardized procedures. Pre-staging materials and tools before changeovers eliminates searching time during transitions. These improvements help manufacturers meet strict requirements for speed and consistency.

Tip: Easy changeover features support fast response to market shifts and reduce labor costs.

Scalability

Scalability ensures that packaging machines grow with the business. Manufacturers can select different plastic sheet sizes, adjust machine bed dimensions, or change forming depths to match production requirements. The table below shows common scalability options:

| Scalability Option | Description |

|---|---|

| Plastic Sheet Sizes | Different sizes can be selected to meet production needs. |

| Machine Bed Dimensions | Customizable dimensions to fit various production scales. |

| Forming Depths | Adjustable depths for different packaging types. |

Multi-lane configurations, ranging from three to twelve lanes, support high-volume production. Compact designs help businesses optimize floor space as they expand. Automatic packing machines adapt to both small producers and large manufacturers, meeting a wide range of requirements.

Technology and Ease of Use

User-Friendly Controls

Modern food packaging machines feature user-friendly controls that simplify daily operations. Operators benefit from touch screen interfaces and intuitive navigation menus. These controls allow quick adjustments and easy monitoring of machine status. Multi-language support ensures that staff from different backgrounds can operate the equipment confidently. Soontrue’s VFFS Automatic Four Side Sealing Packing Machine includes a touch screen interface with multiple language options. This design reduces training time and minimizes errors during production. Operators can access settings, troubleshoot issues, and review performance data with minimal effort.

Machines with advanced user interfaces improve productivity and reduce the risk of mistakes. Companies see faster onboarding for new staff and smoother transitions between shifts.

Integration with Weighers and Scales

Integration with weighing systems enhances the accuracy and efficiency of food packaging machines. Servo control systems work with multi-head weighers, auger scales, and volume cup systems to deliver precise portion control. This technology ensures that each package meets strict weight requirements, reducing product giveaway and waste.

| Benefit | Description |

|---|---|

| Enhanced Accuracy | Precise weighing guarantees consistent bag weight for every package. |

| Reduced Waste | Accurate portion control minimizes scrap and lowers operational costs. |

| Faster, Consistent Filling | Servo motor technology speeds up filling and maintains uniformity. |

| Savings in Money and Resources | Less product wastage leads to significant cost savings, especially in high-volume production. |

Manufacturers who use machines with integrated weighing systems experience improved quality control and greater customer satisfaction.

Automation Features

Automation features in plastic packing machines streamline the packaging process. Servo control systems automate film pulling, sealing, and filling operations. Operators can switch between single and double film pulling structures based on packaging needs. Pneumatic and servo-driven horizontal sealing systems offer flexibility for different products. Automated fault detection and alarm systems monitor performance and alert staff to potential issues. These features reduce manual intervention and keep production lines running smoothly.

Soontrue’s VFFS machine supports seamless integration with automation accessories, such as 10-head weighers and auger scales. Companies benefit from consistent output, reduced labor costs, and the ability to scale production as demand grows.

After-Sales Support and Warranty

Technical Assistance

Reliable technical assistance ensures smooth operation of food packaging machines. Manufacturers often provide expert support through phone, email, or online chat. Trained technicians help users solve problems quickly. They guide operators through troubleshooting steps and answer questions about machine settings. Many companies offer remote diagnostics, which allow technicians to check machine status and recommend solutions without visiting the site. This service reduces downtime and keeps production lines running.

Tip: Companies that invest in strong technical support see fewer disruptions and higher productivity.

Warranty Coverage

Warranty coverage protects buyers from unexpected repair costs. Most reputable manufacturers include a warranty with new machines. This warranty usually covers parts and labor for a set period, such as one year. Some companies offer extended warranty plans for extra peace of mind. Buyers should review warranty terms before purchase. Key points include:

- Duration of coverage

- Parts and labor included

- Exclusions or limitations

A clear warranty policy shows the manufacturer’s confidence in their product. It also reassures buyers that help is available if problems arise.

| Warranty Feature | Benefit |

|---|---|

| Parts Replacement | Reduces repair expenses |

| Labor Coverage | Lowers maintenance costs |

| Extended Options | Provides long-term protection |

Spare Parts Availability

Spare parts availability keeps machines running efficiently. Manufacturers with well-stocked parts centers can ship replacements quickly. Fast delivery prevents long production delays. Companies should check if the supplier offers genuine parts and easy ordering. Some suppliers provide spare parts kits with common items, such as belts, sensors, and sealing elements. These kits help operators perform routine maintenance without waiting for shipments.

Note: Quick access to spare parts extends machine life and supports consistent production.

A strong after-sales support system gives food manufacturers confidence in their investment. It ensures that packaging lines stay productive and reliable.

Staff Training for Food Packaging Machines

Manufacturer Training Resources

Manufacturers provide essential training resources for food packaging machines. They offer detailed manuals, instructional videos, and on-site demonstrations. These resources help operators understand machine functions and safety protocols. Many companies, including Soontrue, supply step-by-step guides that cover setup, operation, and troubleshooting. Training sessions often include hands-on practice with actual equipment. Operators gain confidence by working directly with the machine under expert supervision.

Tip: Comprehensive training materials reduce the risk of errors and improve overall productivity.

Ease of Learning

Modern food packaging machines feature intuitive controls and clear interfaces. Touch screens with multi-language support simplify the learning process for staff. Operators can navigate menus, adjust settings, and monitor performance with minimal effort. Visual cues and prompts guide users through each step. Training programs focus on practical skills, allowing staff to master essential tasks quickly. Companies benefit when employees adapt to new technology without lengthy instruction periods.

| Feature | Benefit |

|---|---|

| Touch screen interface | Faster learning |

| Multi-language support | Accessible for diverse teams |

| Visual prompts | Step-by-step guidance |

Ongoing Support

Ongoing support ensures staff maintain high performance with food packaging machines. Manufacturers offer technical assistance through phone, email, and online platforms. Dedicated support teams answer questions and resolve issues promptly. Many suppliers provide refresher courses and updated training materials as technology evolves. Regular updates keep operators informed about new features and best practices. Companies that invest in continuous training see fewer mistakes and greater efficiency.

Note: Reliable ongoing support empowers staff to handle challenges and maintain consistent production quality.

Selecting the best plastic packing machine for food products involves evaluating several critical factors. The table below highlights the most important considerations for food packaging machinery:

| Factor | Description |

|---|---|

| Nature of the Product | Different food products require specific filling technologies. |

| Speed of Machinery | Production rate impacts food packaging efficiency. |

| Environmental Considerations | Eco-friendly machinery supports sustainable food packaging. |

| Costs | Initial purchase, installation, training, and maintenance affect food business investment. |

| Staff Training | Proper training ensures safe and effective food packaging operations. |

| Flexibility | Adaptability allows for diverse food packaging needs. |

| Warranty | Reliable warranty provides support for food machinery. |

The key to food safety lies in selecting technology that matches the attributes of each food product. Companies should apply these criteria, consult with suppliers, and request product demos or expert consultations to optimize food packaging solutions.

FAQ

What types of food products can a plastic packing machine handle?

A plastic packing machine can process snacks, nuts, dried fruits, powders, and granules. Operators select machines based on product size and texture. Many models offer flexibility for various packaging formats.

How does a food tray sealer machine improve food safety?

A food tray sealer machine creates airtight seals that protect food from contamination. This process extends shelf life and maintains freshness. Many food manufacturers rely on this technology for consistent safety standards.

What maintenance does a food tray sealer machine require?

Operators should clean the sealing surfaces daily and inspect moving parts regularly. Scheduled maintenance includes checking electrical connections and replacing worn components. Proper care ensures reliable operation and reduces downtime.

Can packaging machinery integrate with automated weighing systems?

Packaging machinery often connects with multi-head weighers or auger scales. This integration improves accuracy and efficiency. Automated systems help manufacturers maintain consistent product weights and reduce waste.

How do manufacturers choose between different packaging machines?

Manufacturers evaluate production volume, product type, and packaging format. They consider machine adaptability and long-term costs. Consulting with suppliers helps identify the best solution for specific needs.

Post time: Nov-26-2025