You can make your production faster by using a dumpling packing machine. These machines use automation and smart technology to help you work better and spend less on workers. Many companies now pick machines with robotic arms and AI systems. These machines pack dumplings faster and more accurately.

- The market has small, multifunctional models for any business size.

- New designs focus on keeping things clean and saving energy, so they follow food safety rules.

You get a big advantage in the food industry when you use these solutions.

Key Takeaways

- Automatic dumpling packing machines work faster than people. They let you pack more dumplings in less time.

- These machines help keep the quality the same every time. They make fewer mistakes and keep each dumpling at a high standard.

- Automation helps stop waste by being gentle with dumplings. This saves materials and stops food from being lost when packing.

- You need fewer workers when you use automatic machines. This saves a lot of money on paying workers and teaching them.

- Picking the right equipment for your needs makes work better. It can also help your business get bigger.

How Dumpling Packing Machines Enhance Efficiency

Faster Packing and Output

You can make dumplings faster with an automatic dumpling packing machine. These machines work much quicker than people can by hand. First, you set up the machine and put in the dumplings. Then, the machine does the rest of the work for you. It can pack many dumplings in less time than a group of workers.

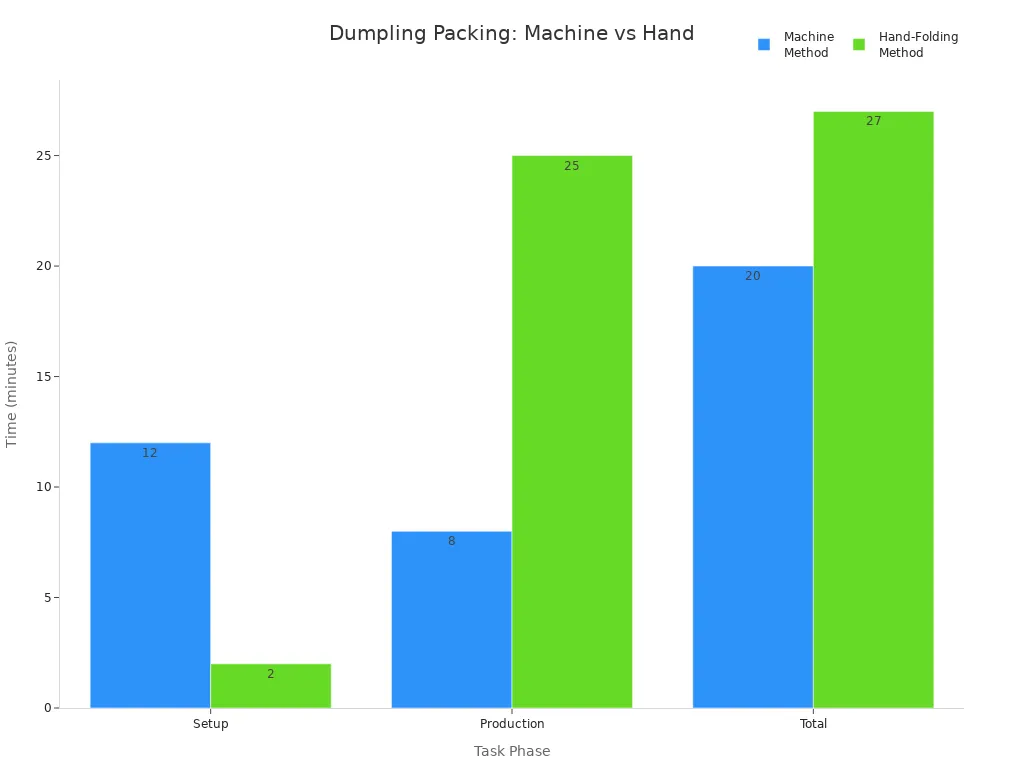

Here is a table that shows how long it takes to pack dumplings by hand and by machine:

| Task Phase | Machine Method | Hand-Folding Method | Analysis |

|---|---|---|---|

| Setup | 12 minutes | 2 minutes | The machine needs to be set up and checked. Hand-folding only needs simple tools. |

| Production | 8 minutes | 25 minutes | The machine packs dumplings quickly and evenly. Hand-folding takes much longer. |

| Total Time | 20 minutes | 27 minutes | For 50 dumplings, the machine saves 7 minutes. The more dumplings you make, the more time you save. |

- People who use a lot of dumplings say they work 3 times faster with automatic machines.

- The automatic dumpling production line keeps working without stopping for long breaks.

Tip: If you want to fill big orders or grow your business, using automatic machines can help you keep up and make your customers happy.

Consistent Quality and Performance

Automatic machines make sure every dumpling is the same high quality. The machine uses special parts to handle dumplings gently. Automatic feeders and alignment systems put dumplings in the right place each time. Sealing units use the same pressure and heat for every package, so you do not get leaks or bad seals.

| Mechanism/Process | Function | Benefit to Quality |

|---|---|---|

| Precision mechanisms | Handle dumplings softly | Fewer mistakes when handling |

| Automatic feeders | Put dumplings in the right spot | Packing looks the same every time |

| Alignment systems | Line up dumplings for sealing | Less chance of mistakes, looks better |

| Sealing units | Use even pressure and heat | Stops leaks and bad seals |

- Photoelectric sensors and cameras check each package for mistakes.

- The machine can change how much filling or pressure it uses right away. This keeps every dumpling the same size and shape, even if the dough or filling is a little different.

Note: When your dumplings are always good, customers complain less and return less. This helps your brand get stronger.

Minimizing Waste and Downtime

Automatic dumpling packing machines help you use less material and waste less food. The tilted design lets the machine handle dumplings gently, so fewer break. The machine keeps each dumpling’s shape and texture, so you lose less product.

- The machine keeps dumplings safe during packing, so you waste less.

- You spend less money on materials because you do not throw away as many broken dumplings.

- The machine wraps and packs dumplings smoothly, so the line does not stop often.

If you want to save money and keep your line running, automatic machines are a good idea. You can spend more time growing your business and less time fixing problems or cleaning up.

When you use an automatic dumpling production line, you work faster, keep quality high, and waste less. These changes help you do better in the food business.

Ways to Reduce Labor Costs with Automation

Fewer Workers Required

If you use an automatic dumpling packing machine, you need fewer workers. The machine does jobs that people did before. You can set up the machine to pack, seal, and sort dumplings. This means you do not need to hire as many people. Your team can do other jobs, like checking quality or helping customers.

Many companies save a lot of money on workers after getting an automatic dumpling production line. The machine can work for many hours without stopping. It keeps the same speed all day. You do not need to pay for extra shifts or overtime. This helps you spend less on workers and keep your business running well.

Tip: If you want to grow your business, automatic machines help you fill more orders without hiring more people.

Lower Training and Supervision Needs

Teaching new workers to pack dumplings by hand takes a lot of time. You have to show each person how to fold, pack, and seal dumplings. With an automatic dumpling making machine, you only need to teach a few people how to use it. The machine does most of the work, so you do not need to teach every step.

You also do not need to watch your team as much. The machine follows set programs and recipes. You can trust it to keep the same speed and quality. This means you do not need as many people to watch or train others.

- You save money on training and classes.

- You spend less time fixing mistakes from new workers.

- Your team can learn to use the machine fast.

Reducing Human Error and Production Risks

Packing by hand can lead to mistakes. Workers might pack the wrong amount or seal packages badly. Sometimes they miss food safety steps. Automatic machines help stop these problems. The machine uses sensors and cameras to check each dumpling and package. You get the same size, shape, and filling every time.

Here is a table that shows how automatic machines help you lower risks:

| Benefit | Description |

|---|---|

| Cost-efficiency and productivity | Automated machines lower labor costs and make production faster, helping small businesses grow. |

| Consistency and quality control | Automation makes sure every dumpling is the same size and has the same filling, which keeps quality high. |

| Regulatory compliance and safety | Modern machines follow food safety rules, so it is easier to keep things clean and safe. |

You can see that automatic machines help you save money and avoid mistakes. The machine keeps your dumplings safe and your line working. You meet food safety rules more easily and do not have to worry about recalls or fines.

Note: Using automatic machines helps you lower risks and save money at the same time.

If you pick the right machine for your needs, you can spend less on workers, keep things safe, and make your business work better. Automatic machines help you stay ahead in the food business.

Implementing an Automatic Dumpling Production Line

Assessing Production Needs

First, you should know what you want to achieve. Think about your goals for the automatic dumpling production line. Check what size and shape your dumplings need to be. Count how many dumplings you want to make each day. Some machines can pack up to 160 dumplings every minute. Decide if you need a special line for different dumpling types or packaging. Make sure your food processing equipment is clean and safe.

| Key Factor | Description |

|---|---|

| Product Specifications | Size and shape of dumplings |

| Production Demands | Number of dumplings needed daily |

| Packaging Speed | Up to 160 dumplings per minute |

| Customization Needs | Different dumpling types or packaging |

| Integrated Production Lines | Seamless workflow between stages |

| Hygiene Standards | Compliance with food safety rules |

Tip: Write down what you need before you pick equipment. This makes it easier to find the best turnkey solution.

Choosing the Right Equipment

Compare different food processing equipment to see what works best. Think about how many dumplings you want to make each day. Make sure the dumpling packing machine fits your needs. Check if it can handle your dumpling’s size and filling. Some machines, like ATLAS STAR, are good for big factories. Others, like Henan Cheng Jinlai, are better for small businesses. Fully automatic machines with automatic feeding and filling help you make more dumplings and keep them good.

| Criteria | Description |

|---|---|

| Daily Production Targets | Number of dumplings produced daily |

| Product Specifications | Size, weight, and flavor variations |

| Variety of Dumpling Types | Styles of dumplings |

| Automatic Feeding | Boosts efficiency |

| Filling Mechanism | Uniform portion sizes |

| Shaping and Molding | Matches market preferences |

| Control Panels | User-friendly operation |

| Cleaning and Maintenance Features | Easy to clean and maintain |

| Power Ratings | Manages electricity costs |

| Energy Efficiency Classifications | Saves on operational costs |

| Total Cost of Ownership (TCO) | Initial and ongoing expenses |

Note: Pick equipment that matches your budget and goals. Choose food processing equipment that is easy to clean and fix, so your line keeps working well.

Integration and Staff Training

Plan how you will add the automatic dumpling production line. Connect your new equipment to your old food processing equipment. Teach your staff how to use the control panels and take care of the machines. Give them simple steps and let them practice. Solve problems like keeping food cold, protecting data, and saving money by using good cold chain and cybersecurity.

| Challenge Type | Description |

|---|---|

| Reliability | Keep cold chain intact to prevent spoilage |

| Security | Protect data with cybersecurity |

| Cost | Manage upfront investment for automation |

Tip: Work with your equipment provider for a turnkey solution. This helps you get the most value and avoid problems.

By following these steps, you can make more dumplings, work faster, and keep your food processing equipment safe. The right automatic dumpling production line helps your business grow and meet what customers want.

Real-World Results and Case Insights

Efficiency Metrics Before and After Automation

Switching to an automatic dumpling packing machine brings big changes. Many companies pack dumplings faster and spend less time on each batch. You can make more dumplings and keep your line moving. The table below shows what changes most after using automatic equipment:

| Operational Change | Description |

|---|---|

| Efficiency Enhancements | You pack dumplings faster and spend less on labor and time. |

| Market Expansion Opportunities | You can make more products and try new dumpling types because your capacity grows. |

| Compliance with Regulatory Standards | You keep quality steady and meet health and safety rules more easily. |

Automatic dumpling making machine models help you fill big orders. You can use smart features like AI-enabled maintenance and adaptive forming molds. These features help you stop downtime and keep your machines working. Many companies in Asia-Pacific pick these solutions to meet more demand and follow city trends.

Labor Cost Savings in Practice

Using automatic dumpling making machine equipment means you need fewer workers. You spend less money on training and watching workers. Companies in France, Italy, and Spain save a lot of money. The table below shows how automation helps you in food manufacturing:

| Country | Current Market Value | Projected Market Value by 2030 | Competitive Advantages |

|---|---|---|---|

| France | USD 25 million | USD 40 million | You get better efficiency, product consistency, and food safety. |

| Italy | USD 20 million | USD 35 million | You increase capacity and meet high quality standards. |

| Spain | USD 18 million | USD 30 million | You work faster and keep up with strict safety rules. |

| Netherlands | USD 15 million | USD 25 million | You use precise, modern dumpling production solutions. |

| Switzerland | USD 12 million | USD 20 million | You focus on precision and meet tough regulations. |

You can learn some important lessons from companies using automatic dumpling making machine equipment:

- Always follow hygiene and safety rules at every step.

- Use new technology, like predictive maintenance, to keep machines working well.

- More people want dumpling production solutions in growing cities.

When you pick the right dumpling packing machine and equipment, you save money and make more dumplings. You stay ahead in food processing and give your business a strong advantage.

Automatic dumpling packing machines help you make more dumplings. They also help you spend less money on workers. You can make 30-50% more dumplings with these machines. You can also lower labor costs by up to 20%.

| Benefit | Metric |

|---|---|

| Production Capacity | 30-50% increase |

| Labor Cost Reduction | Up to 20% decrease |

Automation helps you work faster and keep dumplings good. It also helps you change when the market changes. Check your process to see what you need. Look for machines that are easy to use and save energy. Make sure the company gives good help and support. Talk to equipment sellers to find the best machine for you.

FAQ

How do automatic dumpling packing machines improve food safety?

You use machines that seal dumplings in clean, closed packs. The machines follow strict hygiene rules. Sensors and stainless steel parts help you keep the process safe and easy to clean.

Can you adjust the machine for different dumpling sizes?

Yes, you can change settings on the control panel. You pick the size and shape you want. The machine molds and packs each dumpling to match your needs.

What maintenance does the machine need?

You clean the machine after each use. You check moving parts and sensors often. Most machines have easy-to-remove parts. You follow the guide from the manufacturer for best results.

Is it hard to train staff to use the machine?

No, you can train staff quickly. The control panel uses simple buttons and clear instructions. Most workers learn to use the machine in a short time.

Post time: Nov-20-2025