Finding a packaging machine that is both affordable and durable requires a clear definition of production requirements. The global packaging machinery market is projected to reach USD 80.96 billion by 2030, highlighting the need for smart investments. Businesses should evaluate the total cost of ownership, not just the initial price tag. A Low Price Packing Machine can present unforeseen expenses. This strategic approach ensures the selected equipment delivers long-term value and supports operational growth, turning a simple purchase into a foundational business asset.

Step 1: Define Your Packaging Requirements

An affordable and durable packaging machine is a valuable asset for any business. To find the right one, you need to start by defining your specific packaging requirements. This initial step is crucial because it sets the foundation for all subsequent decisions. A thorough understanding of your product, production speed, and desired packaging format will guide you toward a machine that not only fits your budget but also meets your operational needs for years to come.

Here’s a breakdown of how to define your packaging requirements effectively:

Assess Your Product Characteristics

The first step in selecting a packing machine is to analyze your product's physical properties. These characteristics directly influence the type of machine you need. For example, liquid products require machines with specialized liquid filling capabilities, while fragile items need equipment designed for gentle handling to prevent damage.

Key product specifications to consider include:

·The product's weight: Heavier items may require more robust machine components and support systems.

·The product's shape: Irregularly shaped products can be challenging for standard machines and might necessitate custom-designed solutions.

·The product's dimensions: The machine's infeed and sealing mechanisms must be able to accommodate your product's length, width, and height.

Note: A detailed assessment of your product's nature—whether it's a powder, liquid, solid, or a collection of small items—is essential. This information will help you narrow down your options to machines specifically engineered for your product type.

Determine Your Production Speed Needs

Your required production speed is another critical factor. This is often measured in bags per minute (BPM) or packs per minute (PPM). A small startup might only need a machine that produces 10-20 BPM, while a large-scale operation could require speeds of 100 BPM or more.

To determine your needs, consider your current daily output and project your future growth. It's wise to choose a machine that can handle your current volume with some capacity to spare. This approach prevents you from needing to upgrade too quickly as your business expands. However, avoid over-investing in a machine with excessive speed capabilities that you won't use, as this will unnecessarily increase your initial cost.

Select Your Packaging Format

Finally, you must decide on the final look of your packaged product. The packaging format you choose will impact consumer appeal and product protection. Common flexible packaging formats include:

| Format Type | Description | Common Use Cases |

|---|---|---|

| Pillow Bags | A simple, cost-effective bag with top, bottom, and back seals. | Snacks, coffee, powders |

| Gusseted Bags | Bags with expandable sides, allowing them to hold more volume. | Pet food, bulk grains |

| Stand-Up Pouches | Pouches with a bottom gusset that allows them to stand upright. | Sauces, granola, liquids |

| Sachets/Packets | Small, four-sided sealed packets for single-serving products. | Condiments, sugar, spices |

Selecting your desired format is a key step because different machines are designed to produce specific bag types. A Vertical Form Fill Seal (VFFS) machine is excellent for creating pillow bags, while a specialized pouch filler is needed for pre-made stand-up pouches. Clearly defining your packaging format ensures you invest in a machine that produces the exact package style your brand requires.

Plan for Future Growth

Selecting a packing machine is a significant capital investment. A business must look beyond its immediate needs and consider its long-term strategic goals. A machine that only meets current demands may quickly become obsolete, forcing a costly replacement sooner than anticipated. Strategic foresight ensures the chosen equipment can support the company as it scales, making it a truly durable and affordable asset over its lifespan.

Anticipating future production volumes is a critical first step. A business should project its growth over the next three to five years. This helps determine if a machine offers the necessary scalability. Answering these questions provides clarity:

·Can the machine's speed be upgraded later?

·Will it handle a higher throughput without significant performance loss?

·Does the manufacturer offer upgrade paths for this model?

Pro Tip: Look for machines with a modular design. Modular equipment allows a business to add new capabilities, such as different fillers or labelers, as its product line expands. This flexibility prevents the need to purchase an entirely new system to accommodate new packaging formats or product types.

Ultimately, planning for growth involves finding a balance. A company should not overspend on a machine with features it will not use for many years. However, it also should not choose a basic model with no room for expansion. The ideal machine meets current production requirements comfortably while offering a clear and cost-effective path to handle future increases in demand. This forward-thinking approach is fundamental to maximizing the return on investment.

Step 2: Compare Machine Types and Automation Levels

After defining your requirements, the next step is to explore the available machinery. The market offers a wide range of options, each with different levels of automation and specific applications. Understanding these differences helps a business narrow its search to the most suitable and cost-effective solutions.

Semi-Automatic vs. Fully Automatic Systems

The level of automation directly impacts labor costs, production speed, and initial investment.

·Semi-Automatic Systems require an operator to manually load products, position bags, or initiate the sealing cycle. These machines are less expensive upfront and offer a good entry point for smaller operations.

·Fully Automatic Systems handle the entire packaging process from start to finish with minimal human intervention. They offer higher speeds and greater consistency.

While fully automatic machines have a higher initial cost, they often deliver a rapid return on investment. Many businesses see a payback within 6 to 18 months due to reduced labor costs and increased throughput. For some specialized systems, like an automated coil packing line, a full ROI can be achieved in 18 to 36 months.

Common Machines: VFFS, Flow Wrappers, and Pouch Fillers

Different machines are engineered for specific products and package styles. Three common types are:

1.Vertical Form Fill Seal (VFFS) Machines: These create bags from a roll of film, fill them with product, and seal them vertically. They are ideal for powders, liquids, and granular items.

2.Flow Wrappers (HFFS): These wrap products horizontally and are perfect for solid items like candy bars or baked goods.

3.Pouch Fillers: These machines fill and seal pre-made pouches, such as stand-up pouches or sachets.

The table below compares VFFS machines and flow wrappers:

| Feature | VFFS Machines | Flow Wrappers (HFFS) |

|---|---|---|

| Primary Use | Powders, liquids, granulars | Solid, individual items |

| Footprint | Compact, vertical design | Longer, requires more floor space |

| Speed | Generally slower | Very high speed (up to 400 PPM) |

| Orientation | Seals packaging vertically | Seals packaging horizontally |

New vs. Used and Refurbished Options

A business must decide whether to invest in a new, used, or refurbished machine. New equipment offers the latest technology, full customization, and a manufacturer's warranty. However, a used Low Price Packing Machine provides a lower initial cost and immediate availability.

Buying used equipment can be a gamble. A business might acquire a machine "as is" from an auction, which could be a great deal or a money pit requiring costly repairs. It is crucial to verify that service and parts are still available for any used model.

Refurbished machines offer a middle ground. They are professionally inspected, repaired, and often come with a limited warranty, providing more reliability than a typical used option.

Step 3: Is a Low Price Packing Machine Worth the Risk?

The allure of a low initial price is strong, especially for businesses managing tight budgets. However, a decision based solely on the upfront cost can lead to significant long-term expenses and operational headaches. A business must carefully weigh the immediate savings against the potential risks. Evaluating whether a Low Price Packing Machine is a wise investment or a future liability is a critical step in the selection process.

Understanding Initial Cost vs. Long-Term Value

True value extends far beyond the initial purchase price. It encompasses the machine's entire operational lifespan, including its efficiency, reliability, and the support behind it. Many experienced manufacturers build their philosophy on this principle. For example, some industry leaders learned early on that cutting corners on equipment quality invariably leads to higher costs from constant breakdowns, frequent maintenance, and lost production time.

This experience teaches a valuable lesson: a business should prioritize robust, durable equipment over the lowest price tag. The goal is to find a solution that addresses specific operational problems, such as production bottlenecks or worker safety concerns. A supplier should act as a long-term partner, offering expertise that supports sustained growth. This approach ensures a clear and positive return on investment.

The following table breaks down how this value-focused mindset can be applied in a factory setting.

| Lesson Learned | Application for Your Factory | Outcome for Your Factory |

|---|---|---|

| Value of Quality | Prioritize robust, durable equipment over the lowest price. | Fewer breakdowns, lower maintenance, consistent output. |

| Problem-Solving Focus | Choose solutions tailored to your specific bottlenecks and safety concerns. | Direct resolution of operational issues, improved safety. |

| Partnership over Sales | Select a supplier offering long-term support and expertise. | Reliable operations, informed decisions, sustained growth. |

| ROI-Driven Decisions | Invest where a clear, positive return on investment is demonstrable. | Increased profitability, reduced costs, optimized capital use. |

Hidden Costs of Cheaper Machines

A machine with a low sticker price often conceals significant downstream expenses. These hidden costs can quickly erase any initial savings and negatively impact a company's bottom line. A Low Price Packing Machine is more susceptible to a range of common failure points that result in costly downtime and wasted resources.

Frequent issues associated with less durable equipment include:

1.Jammed or Stuck Products: Poorly engineered components can cause products to get stuck, halting the entire production line.

2.Incorrectly Sealed Packages: Worn-out sealing jaws or improper temperature controls lead to package failures, product spoilage, and material waste.

3.Inaccurate Fill Levels: Faulty fillers or sensors result in over-filling or under-filling, which wastes product and can lead to compliance issues.

4.Malfunctioning Sensors: Low-quality sensors may fail to detect products or film, causing machine errors and interruptions.

5.Frequent Machine Downtime: Breakdowns from mechanical or electrical issues are common, requiring constant intervention and repair.

6.Electrical Issues: Blown fuses, faulty switches, and damaged wiring can create safety hazards and require specialized technician assistance.

7.Poor Quality Packages: The final output often looks unprofessional due to inconsistent machine performance, damaging brand perception.

8.Operator Error: Complex or unreliable controls can increase the likelihood of mistakes, leading to further downtime and waste.

These problems translate directly into financial losses from lost production, increased labor for repairs, and higher material consumption.

When an Entry-Level Machine Makes Sense

Despite the risks, an entry-level or lower-cost machine is not always the wrong choice. In certain business scenarios, it represents a strategic and sensible investment. The key is to align the machine's capabilities with the company's current scale and future goals.

An entry-level machine is often a suitable choice for:

·Low-Volume Startups: A new business with limited initial orders does not need a high-speed, high-capacity system. A basic machine can meet current demand without requiring a massive capital outlay.

·Market Testing: Companies launching a new product line can use an affordable machine to test market viability before committing to a larger investment.

·Businesses with Growth Plans: Many manufacturers offer modular solutions. These systems provide the flexibility to start with basic equipment and add capabilities, such as new fillers or labelers, as the business grows. This approach allows a company to improve its business scale incrementally.

Note: When considering an entry-level option, a business should still prioritize build quality and supplier support. A well-made basic machine from a reputable manufacturer will always outperform a feature-rich but poorly constructed alternative.

Step 4: Key Features That Signal Durability

Once a business understands its needs, it must shift its focus to the machine itself. A durable packing machine is more than just a sturdy frame; its longevity depends on the quality of its components, the reliability of its core functions, and its ability to adapt to changing production demands. Examining these key features helps separate a machine built to last from one that will cause future problems.

Look for Quality Construction and Materials

The physical build of a packing machine provides the first clue to its durability. A robust frame, often constructed from heavy-gauge stainless steel, is essential, especially in food and beverage applications where sanitation and corrosion resistance are paramount. However, true quality lies deeper, within the machine's electrical and mechanical components. The brands used for critical parts like PLCs (Programmable Logic Controllers) and servo motors are strong indicators of reliability.

High-quality components ensure consistent performance under demanding, repetitive cycles. For instance, a packaging company that implemented Mitsubishi’s FX5U PLC for its high-speed operations saw a 20% increase in output within six months. The system's modular design allowed for efficient scaling, demonstrating how a reliable PLC directly contributes to productivity and long-term value.

When evaluating a machine, a business should inquire about the brands of its core components. Reputable manufacturers often use parts from industry-leading suppliers.

·Panasonic's MINAS A6 series servo motors and drives are widely trusted in packaging and printing, holding a significant share of the global market.

·Schneider Electric's Lexium series drives are favored in logistics and food and beverage for their smart connectivity and operational flexibility.

A machine built with components from these or other well-regarded brands is more likely to offer dependable service for years.

Evaluate the Sealing Mechanism

The seal is arguably the most critical aspect of a finished package. It protects the product from contamination, preserves freshness, and prevents leaks. A machine's ability to create strong, consistent seals directly impacts product quality and brand reputation. Therefore, a thorough evaluation of the sealing technology is non-negotiable. The two primary technologies are traditional heat sealing and modern ultrasonic sealing.

Each method has distinct implications for cost, speed, and maintenance.

| Criteria | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Energy Consumption | High; requires continuous heating | Low; consumes power only during the sealing cycle |

| Cycle Speed | Moderate; includes a cooling phase | Very fast; no cooling required |

| Contaminant Sealing | Less effective through contaminants | Seals directly through small contaminants |

| Material Savings | Produces wider seals (4–6 mm) | Can reduce seal width by up to 75% |

| Maintenance | More complex; frequent checks needed | Stable and easier to maintain |

| Initial Cost | Lower upfront cost | Higher upfront cost |

While heat sealing systems have a lower initial cost, ultrasonic sealing often delivers a better long-term return. Ultrasonic machines are more energy-efficient because they only draw power during the brief sealing cycle. They also allow for narrower seals, leading to significant material cost savings over time. Though the specialized components have a higher replacement cost, their durability means less frequent maintenance, contributing to better machine longevity and overall efficiency.

A durable sealing mechanism also minimizes package failures. While recent trends show an increase in packaging failure rates, a high-performance machine should operate with near-perfect consistency. Businesses should ask potential suppliers about their expected seal failure rates.

| Industry/Company | Acceptable Failure Rate |

|---|---|

| Lubrication and Chemical Packaging (General) | Up to 1% (10,000 ppm) |

| Pack Logix (High-Precision) | 0.05% (500 ppm) |

A low failure rate prevents product waste, protects brand integrity, and ensures operational efficiency.

Check for Machine Flexibility and Changeover Speed

In today's fast-paced market, production needs can change quickly. A durable machine is not just one that runs for a long time, but one that adapts efficiently. Machine flexibility, particularly the speed of changeovers, is a key feature of a valuable long-term asset. A changeover involves switching the machine from one product, bag size, or film roll to another. Lengthy changeovers create costly downtime, turning a high-speed machine into a production bottleneck.

Pro Tip: A skilled operator should be able to complete a full changeover on a modern VFFS machine in approximately 15 minutes. This serves as a valuable benchmark when discussing machine capabilities with suppliers.

Machines designed for flexibility incorporate features that simplify and expedite this process. A business should look for:

·Tool-less adjustments: Levers, knobs, and clamps that can be adjusted by hand.

·Digital HMI with recipe storage: Allows operators to save and recall settings for different jobs with the touch of a button.

·Color-coded or numbered change parts: Makes it easy to identify and install the correct components for a specific setup.

A machine that combines robust construction with rapid changeover capabilities provides the durability and agility needed to support business growth for years to come.

Step 5: Evaluate Supplier Reliability and Support

A packing machine is only as good as the company that stands behind it. A reliable supplier provides more than just equipment; they offer a partnership that ensures long-term operational success. Evaluating a manufacturer's reputation, service policies, and parts availability is essential to protect the investment.

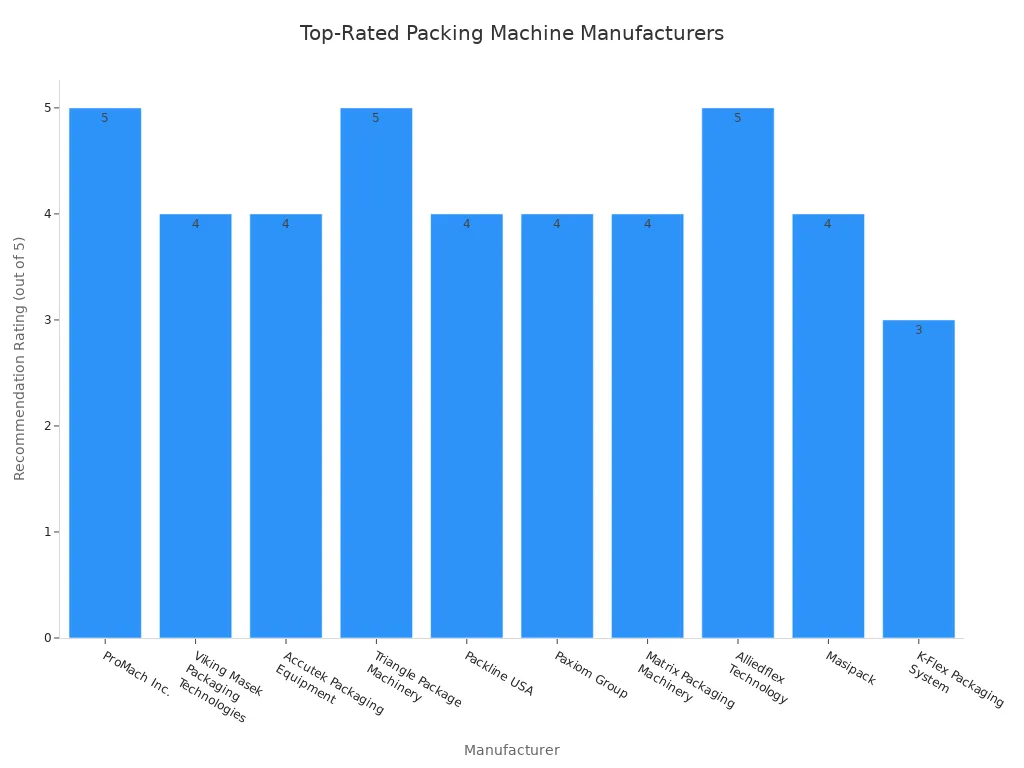

Research Manufacturer Reputation

A manufacturer's history and industry standing offer valuable insights into its reliability. A business should investigate potential suppliers thoroughly. Long-standing companies often demonstrate consistent quality and customer satisfaction. For example, some manufacturers like FUJI Machinery have been chosen by customers for over 70 years, while others like Adelphi hold ISO 9001:2015 certifications and industry awards. These credentials signal a commitment to excellence.

Customer reviews and industry ratings provide another layer of validation. A business can use these resources to gauge the real-world performance and support offered by different suppliers.

Inquire About Warranty and After-Sales Service

The warranty is a direct reflection of a manufacturer's confidence in its product. A business should carefully review the terms before making a purchase. A standard one-year warranty typically begins after the machine passes its Site Acceptance Test.

Note: A comprehensive warranty should clearly define what is and is not covered. Key points to clarify include:

·Coverage: Defects in non-wear parts and software issues that prevent normal operation.

·Exclusions: Normal wear items like belts and heaters, or damage caused by operator error.

·Service: Damages caused by the manufacturer's own technicians during installation or repair.

Understanding these details helps a business avoid unexpected costs for repairs that fall outside the warranty agreement.

Confirm Spare Parts Availability

Downtime is expensive. The availability of spare parts and responsive technical support is critical to keeping a production line running. A business must confirm that a supplier maintains a healthy inventory of critical components and can ship them quickly.

Equally important is the supplier's service response time. A business should ask about the different tiers of support available. Leading suppliers often offer structured service plans to meet varying customer needs.

| Service Type | Response Time (M-F 8am-4pm) |

|---|---|

| Priority Plus | 24-48 hours or less |

| Standard Service | 72 hours or less |

Clarifying these support levels ensures a business can get a technician on-site quickly when a problem arises, minimizing production losses.

Step 6: Calculate the Total Cost of Ownership (TCO)

A smart investment looks beyond the initial price tag. Calculating the Total Cost of Ownership (TCO) provides a comprehensive financial picture of the machine over its entire lifespan. This analysis includes upfront costs, ongoing expenses, and potential savings. A business that performs a thorough TCO calculation can accurately compare different machines and identify the one that offers the best long-term value.

Factor in Installation and Training Costs

The purchase price is just the beginning. Professional installation and operator training are critical investments that ensure the machine runs correctly from day one. Many reputable manufacturers provide on-site setup and commissioning services, which may be included in the capital cost or listed as a separate line item. This professional setup minimizes initial errors.

Comprehensive training is equally important. It equips operators with the skills to run the machine efficiently and safely. The level of training required often depends on the machine's complexity.

| Cost Category | Semi-Automatic | Fully Automatic |

|---|---|---|

| Installation/Setup | Included in capital cost | Included in capital cost |

| Training Requirements | Basic operator training | Technical specialist training |

Investing in proper training reduces user errors, boosts productivity, and helps a business maximize its return on investment.

Analyze Ongoing Maintenance Expenses

Every machine requires maintenance to ensure its longevity and performance. A preventative maintenance plan is essential for minimizing downtime and avoiding costly emergency repairs. For high-volume equipment, monthly or quarterly maintenance is often recommended. A typical schedule includes several key tasks:

·Scheduled inspections (daily, weekly, monthly)

·Lubrication of moving parts like gears and chains

·Cleaning of belts, sealing jaws, and sensors

·Checking and adjusting tension and alignment

·Replacing worn components before they fail

A Low Price Packing Machine may require more frequent and expensive maintenance, quickly eroding any initial savings.

Consider Labor and Material Cost Savings

A new packing machine should generate a positive return on investment. Automation offers one of the most significant opportunities for savings. By transitioning from manual to automated systems, small businesses can reduce labor costs by 50-67%. This often translates to annual savings between $25,000 and $35,000. For example, one frozen food producer cut its labor expenses by 65% after implementing an automated bagging system. In addition to labor, automation improves fill accuracy and seal consistency, reducing product and material waste. These combined savings are a crucial component of the TCO calculation.

Step 7: Making Your Final Decision

After extensive research and evaluation, a business reaches the final stage of the selection process. This step requires careful verification to ensure the chosen machine and supplier will meet long-term expectations. Taking these final measures protects the investment and solidifies a successful partnership.

Always Request a Live Demonstration

A business should never purchase a packing machine without seeing it operate first. A live demonstration, either in person or via video, is the best way to validate a supplier's claims. This test provides an opportunity to see how the machine handles the company's specific products and packaging materials.

Pro Tip: A business should send its own product samples and film rolls to the manufacturer for the demonstration. This allows for a true performance test, revealing how the machine will function in the actual production environment. It helps confirm speed, seal quality, and overall efficiency.

Ask for and Check Supplier References

A reputable supplier will gladly provide a list of current customers. A business should contact these references to gather firsthand feedback. Speaking with other users offers unbiased insights into the machine's day-to-day performance, reliability, and the quality of the manufacturer's after-sales support. This step helps verify the supplier's reputation and builds confidence in the final decision.

Carefully Review the Purchase Contract

The purchase contract is the legally binding agreement that outlines the responsibilities of both the buyer and the seller. A business must review this document meticulously before signing. It serves as the ultimate protection for the investment. Key clauses demand close attention to prevent future disputes and ensure the machine meets all promised standards.

A thorough contract review should focus on several critical areas:

·Quality and performance standards: This section defines the machine's operational benchmarks. It ensures the equipment will perform as specified.

·Liability and risk allocation: This clause clarifies who is responsible for potential issues, often using indemnification provisions or liability caps.

·Warranties: The contract must detail product warranties, confirming the machine is free from defects and fit for its intended purpose.

·Remedies: This part specifies the actions, such as repair, replacement, or termination, that are available if one party breaches the agreement.

Choosing an affordable packing machine that lasts requires a balance between upfront cost and long-term reliability. A business makes a smart investment by defining its needs, evaluating machine durability, and calculating the total cost of ownership. This thorough evaluation process protects the capital expenditure. It ensures the new machine supports operational goals for years to come, delivering sustained value and a strong return on investment.

FAQ

What is the most important factor when choosing a packing machine?

The Total Cost of Ownership (TCO) is the most critical factor. A business should evaluate long-term expenses like maintenance and parts, not just the initial price. This approach ensures the machine delivers true value and a strong return on investment over its lifespan.

Is a used packing machine a good investment?

A used machine can be a good investment if a business verifies its condition and parts availability. Refurbished options from reputable suppliers often provide a safer middle ground. They offer cost savings with a limited warranty, reducing the risk associated with "as-is" purchases.

How important is the manufacturer's warranty?

The warranty is very important. It reflects the manufacturer's confidence in its equipment. A business must review the terms to understand coverage for parts, labor, and potential exclusions. A comprehensive warranty protects the investment and minimizes unexpected repair costs after installation.

Why should a business request a live demonstration?

A live demonstration validates a machine's performance. It allows a business to test its specific products and film, confirming speed and seal quality. This step ensures the machine meets operational requirements before the final purchase is made, preventing costly surprises.

Post time: Dec-19-2025