The global demand for chili powder continues to expand, presenting a significant opportunity for producers. This growth underscores the need for efficient production.

| Metric | Value |

|---|---|

| Global Chili Powder Market CAGR (2025-2031) | 6.4% |

Businesses often begin their search for automation here. A base model Vertical Form Fill Seal (VFFS) machine for chili powder typically costs between $7,000 and $15,000. This initial figure is only a starting point. The final Chilli Powder Packing Machine Price depends heavily on specific configurations and necessary additions.

Core Factors That Determine the Base Price

The initial quote for a VFFS machine is rarely the final number. Several core factors directly influence the base price, turning a standard model into a specialized solution tailored to a business's unique production needs. Understanding these elements is the first step toward a transparent investment.

Machine Configuration and Customization

A base machine performs the fundamental tasks of forming, filling, and sealing. However, most chili powder production lines require specific enhancements. Each customization adds to the total cost. Common additions include:

·Date Coders: For printing expiration dates and batch numbers.

·Dust Collection Systems: Essential for managing fine chili powder dust.

·Nitrogen Gas Flushing: To extend product shelf life.

·Additional Bag Formers: For producing multiple pouch sizes on one machine.

Note: A highly customized machine will always have a higher initial cost than a standard, off-the-shelf model. Businesses must evaluate which features are essential versus optional.

Production Speed and Capacity

Production speed, measured in bags per minute (BPM), is a primary driver of the Chilli Powder Packing Machine Price. Higher speeds demand more powerful motors, advanced electronics, and robust mechanical components to maintain accuracy and reliability.

| Speed Tier | Typical BPM | Price Impact |

|---|---|---|

| Entry-Level | 15-30 BPM | Standard |

| Mid-Range | 30-60 BPM | Moderate Increase |

| High-Speed | 60+ BPM | Significant Increase |

A machine designed for higher output requires a more substantial investment upfront but delivers greater throughput and a lower cost per bag over time.

Material and Build Quality

The construction materials directly affect machine longevity and price. Most machines use food-grade stainless steel SS304 as a standard. However, some spices, including certain types of chili powder, can be mildly corrosive. An upgrade to SS316 stainless steel provides superior corrosion resistance but increases the material cost of the machine frame and contact parts. This choice ensures durability when handling more aggressive products, protecting the investment long-term.

Decoding the Chilli Powder Packing Machine Price Breakdown

The base price of a VFFS machine is just the beginning. The most significant cost drivers are found in the components that control precision, accuracy, and packaging style. A detailed breakdown of these parts reveals where the money truly goes and how each choice impacts performance.

Servo Motor vs. Stepper Motor Costs

The motor is the heart of a packing machine, controlling the film pulling and filling mechanisms. The choice between a stepper motor and a servo motor is one of the most critical decisions affecting both performance and cost.

·Stepper Motors: These are the standard, more economical option. They operate on an open-loop system, moving in discrete steps. While cost-effective for lower-speed applications, they can lose steps if overloaded, potentially compromising accuracy.

·Servo Motors: These represent a significant upgrade. They use a closed-loop feedback system to continuously monitor and adjust their position. This ensures exceptional accuracy and reliability, even under changing loads.

Servo motors deliver superior performance for demanding applications. Their advantages include:

·High-Speed Operation: They maintain torque and performance at speeds well over 1,000 RPM.

·Dynamic Load Adjustment: They instantly adapt to variations in film tension or product weight.

·Maximum Throughput: Their rapid acceleration and deceleration capabilities boost overall production speed.

·Precision Under Load: The closed-loop system provides continuous position correction, guaranteeing high accuracy and repeatability.

The performance difference is a key factor in the Chilli Powder Packing Machine Price. While a servo-driven machine costs more upfront, it delivers higher speeds and greater accuracy, reducing product waste and increasing output.

| Attribute | Stepper Motor | Servo Motor |

|---|---|---|

| Usable Speed Range | Best under 1000 RPM | Commonly 3,000–5,000 RPM |

| Positional Accuracy | Deterministic steps; may miss steps if overloaded | High; continuously corrected via feedback |

| Repeatability | Good (if not overloaded) | Excellent (adaptive to disturbances) |

| Peak Torque | Limited and drops at high speeds | High and consistent across a wide range of speeds |

Auger Filler and Weigher Upgrades

For a fine, dusty product like chili powder, the filling system is paramount. The standard dosing method is an auger filler, which uses a rotating screw to dispense a specific volume of powder into each bag.

Pro Tip: The precision of the auger filler directly impacts profitability. An inaccurate filler leads to overfilling (giving away free product) or underfilling (risking non-compliance and customer dissatisfaction).

High-precision auger fillers, often equipped with their own servo motors, provide superior weight control. The cost for these critical components can vary widely based on their sophistication and build quality.

| Auger Filler Model Type | Example Price Range |

|---|---|

| High-Precision Automatic Auger Filler | $4,500 - $5,000 |

| Sachet Packing Machine with Integrated Auger | $12,500 - $13,000 |

| High-Precision Dual Auger System | $19,000+ |

To further guarantee accuracy and safety, businesses often add ancillary quality control equipment. A checkweigher verifies that each finished bag meets the target weight, while a metal detector scans for contaminants. A combination system is an efficient solution, with estimated costs ranging from $5,000 to $8,000 for a new unit. Used and rental options are also available for businesses looking to manage initial capital outlay.

Pouch Size and Sealing Type Options

The final appearance of the product on the shelf influences machine selection and cost. The two most common bag types for chili powder are pillow bags and stand-up pouches.

A machine configured for simple pillow bags is the most cost-effective option. However, for retail environments, stand-up pouches (doypacks) offer superior shelf appeal and functionality. Creating these more complex bags requires additional mechanical components on the VFFS machine, such as gusset formers and specialized sealing jaws, which increases the price.

| Feature | Pillow Bag | Stand-Up Pouch |

|---|---|---|

| Cost | Lower | Higher due to mechanical complexity |

| Best For | Bulk products, food service | Retail products, premium branding |

| Shelf Appeal | Simple, functional | Premium, eye-catching, stands upright |

| Reseal Options | Typically single-use | Can accommodate zippers or tear notches |

Adding features like a zipper applicator or a gas flush system for stand-up pouches further adds to the machine's complexity and final cost. Businesses must weigh the marketing benefits of premium packaging against the higher initial equipment investment.

Premium vs. Standard Electronic Components

The electronic components are the brain of a VFFS machine. They control every function, from film pulling and sealing temperature to filling accuracy and overall speed. The choice between standard and premium electronics is a critical decision that directly influences machine reliability and the long-term cost of ownership.

·Standard Components: These are often sourced from lesser-known or regional manufacturers. They provide basic functionality at a lower initial cost. However, they may lack the robust performance and global support network of premium brands.

·Premium Components: These come from internationally recognized brands like Siemens, Schneider Electric, Omron, or Panasonic. These components are engineered for higher durability, precision, and consistent performance under demanding industrial conditions.

The key electronic parts to scrutinize include the Programmable Logic Controller (PLC), the Human-Machine Interface (HMI), and various sensors.

| Component | Standard Option | Premium Option (e.g., Siemens, Omron) |

|---|---|---|

| PLC (Brain) | Basic processing, may struggle with complex tasks. | Faster processing, handles high-speed, multi-function operations reliably. |

| HMI (Touchscreen) | Slower response time, less intuitive interface. | Responsive, user-friendly interface with better diagnostics. |

| Sensors | Lower precision, higher potential for failure. | High-precision and durable, ensuring accurate machine function. |

Expert Tip: Always request a detailed list of electronic component brands in your quote. A supplier using reputable brands demonstrates a commitment to quality and reliability. This transparency is a key indicator of a trustworthy partner.

Opting for premium electronics increases the initial Chilli Powder Packing Machine Price. However, this investment provides significant long-term advantages. Businesses benefit from enhanced machine uptime, easier access to replacement parts globally, and superior technical support. A machine with reliable electronics avoids costly production halts, ultimately delivering a better return on investment.

Uncovering Hidden Costs You Must Account For

An exceptional machine quote can quickly become less attractive when hidden costs emerge. The initial purchase price is only one part of the total investment. A savvy buyer must account for additional expenses related to logistics, supplementary equipment, and long-term operations. These "hidden" costs are predictable and should be included in any comprehensive budget to avoid financial surprises.

Shipping, Installation, and Training Fees

The journey from the manufacturer's factory to a fully operational production line involves several service-based costs. These fees are rarely included in the initial machine price.

·Shipping and Freight: VFFS machines are heavy and bulky. International shipping, customs clearance, and local delivery can add thousands of dollars to the final bill. Businesses should request a detailed shipping quote, including insurance.

·Installation: Professional installation ensures the machine is set up correctly for optimal performance and safety. Suppliers often charge for this service.

·Operator Training: Proper training is crucial for maximizing efficiency and minimizing downtime. Many suppliers offer on-site training services. For example, some industrial equipment suppliers charge around $1,000 per day plus travel expenses for operator training. Other companies, like MC Machinery Systems, provide custom quotes based on the machine's age and complexity. Factoring in these expert services is a wise investment in operational readiness.

Budgeting Tip: Always ask the supplier for an itemized quote that separates the machine cost from shipping, installation, and training fees. This transparency helps in comparing offers accurately.

Essential Ancillary Equipment Costs

A VFFS machine does not operate in isolation. It requires upstream and downstream equipment to create a complete, automated packaging line. These ancillary machines are essential for feeding the product and ensuring quality control.

The most critical piece of ancillary equipment for a chili powder line is the feeding system. This device transports the powder from a bulk container to the VFFS machine's hopper. A screw conveyor or bucket elevator is typically used for this task. A customized stainless steel screw elevator suitable for food powders can cost between $3,500 and $6,000. This equipment automates the feeding process, maintaining a consistent flow of product and reducing manual labor.

Other necessary ancillary equipment includes:

·Air Compressor: VFFS machines use pneumatic components that require a steady supply of compressed air.

·Take-Away Conveyor: This conveyor moves finished bags away from the machine for packing into cases.

·Checkweigher/Metal Detector: As mentioned earlier, these quality control units ensure product safety and weight accuracy.

Long-Term Operational and Maintenance Costs

The investment in a packing machine continues long after the initial purchase. Operational and maintenance costs represent a significant portion of the total cost of ownership over the machine's lifespan.

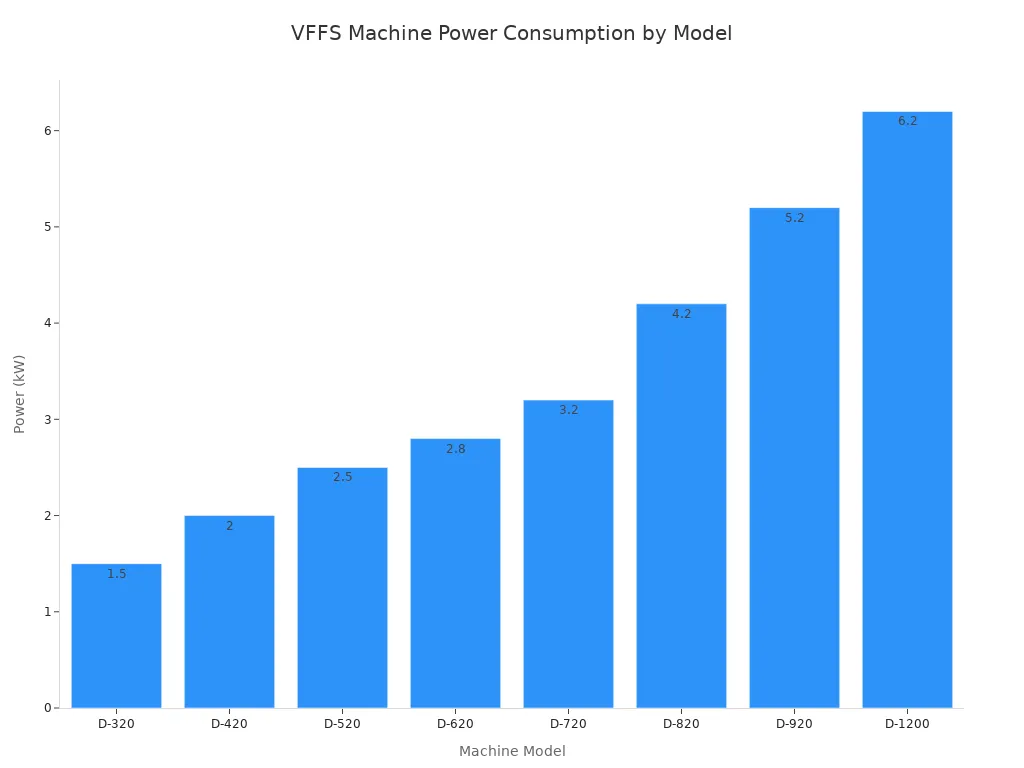

Operational Costs:The primary ongoing operational cost is electricity consumption. The power required depends on the machine's size and speed. A typical VFFS machine consumes between 1.5 kW and 6.2 kW per hour.

For example, a mid-range machine using 2.5 kW of power and operating for 8 hours a day will consume 20 kWh daily. Businesses should calculate this cost based on their local electricity rates.

Maintenance Costs:Regular maintenance is essential to keep the machine running efficiently and prevent costly breakdowns. These costs include:

·Spare Parts: Wearable parts like sealing jaws, cutting blades, and heating elements need periodic replacement.

·Consumables: Items like thermal transfer ribbons for date coders are a recurring expense.

·Preventive Maintenance Kits: Many suppliers offer kits containing common wear parts for scheduled maintenance.

Smart Planning: Businesses should request a recommended spare parts list and their prices from the supplier. Budgeting for these parts from day one ensures that maintenance activities do not disrupt production schedules.

How to Know You're Getting a Fair Deal

Navigating quotes from multiple suppliers requires a systematic approach. Securing a fair price involves more than just comparing the final numbers. It demands a thorough evaluation of technical specifications, a keen eye for potential overpricing, and a deep dive into the supplier's long-term value.

Create a Price Comparison Checklist

A structured comparison is the best defense against confusion. Businesses can use several template styles to organize information from different vendors. A Product Feature Comparison Template is particularly effective. It allows buyers to create a matrix comparing key technical specifications side-by-side.

This checklist should detail critical performance metrics for each quoted machine:

·Packing Speed: Bags per minute (BPM)

·Bag Dimensions: Supported length and width ranges

·Filling Range: Minimum and maximum weight capacity

·Filling Accuracy: The acceptable weight deviation (e.g., ±0.5%)

·Control System: PLC and HMI brands

·Material of Construction: SS304 vs. SS316

A detailed checklist transforms complex quotes into an easy-to-read format. It ensures an apples-to-apples comparison, highlighting which supplier offers the best performance for the price.

Red Flags That Signal Overpricing

A high price is not always a red flag, but over-specification often is. Suppliers may quote a machine with capabilities far beyond a business's actual needs, inflating the cost unnecessarily. For example, a machine might be quoted with ultra-tight manufacturing tolerances of +/- 0.001” when standard tolerances of +/- 0.005” are perfectly adequate for the application.

Key Insight: Direct communication is vital. A buyer should clearly state their production requirements, including speed, bag size, and acceptable tolerances. If a supplier knows that tolerances can be loosened, they can often provide a lower quote without sacrificing performance.

Other red flags include:

·Vague Specifications: Quotes lacking detail on component brands or materials.

·Unbundled Essential Features: Charging extra for standard items like a basic auger filler.

·High-Pressure Sales Tatics: Pushing for a quick decision without allowing for due diligence.

Evaluating Supplier Reputation and Support

A lower machine price can become expensive if the supplier offers poor support. A reputable partner provides value long after the sale through a robust warranty and comprehensive after-sales service. Buyers should investigate a supplier's track record. Customer testimonials, especially those mentioning long-term reliability, are a strong indicator of quality.

A solid support package typically includes:

·Warranty: A standard 12-month warranty covering parts and labor is common.

·Technical Support: Access to 24/7 online support and remote diagnostics.

·Spare Parts: A reliable supply of genuine spare parts at competitive prices.

·Training: On-site or remote training for operators and maintenance staff.

Always review the warranty terms and service agreements. A supplier committed to proactive support and operational continuity is a true partner in success.

A buyer's final Chilli Powder Packing Machine Price depends on machine configuration, production speed, and component quality. Businesses should anticipate a realistic, all-inclusive investment. This total cost for a fully operational setup will likely range from $12,000 to $25,000 or more.

To ensure a fair deal, buyers must demand a detailed, itemized quote from suppliers. This empowers them to compare offers effectively and avoid overpaying for their equipment.

FAQ

What is the realistic total cost for a chili powder packing line?

A base machine costs $7,000 to $15,000. A complete, operational line including ancillary equipment like feeders and conveyors typically requires a total investment of $12,000 to $25,000+. This final price depends on customization, speed, and component quality.

Why should a business choose a servo motor over a stepper motor?

A business chooses a servo motor for superior speed and precision. Its closed-loop system guarantees high accuracy, even under heavy loads. This reduces product waste and increases overall throughput, justifying the higher initial cost for high-volume production.

Is the more expensive SS316 stainless steel necessary?

The choice depends on the product's properties. Standard SS304 is sufficient for most applications. A business should select SS316 stainless steel if its chili powder is particularly abrasive or corrosive. This upgrade ensures long-term machine durability and prevents contamination.

How can a buyer ensure they receive a transparent quote?

A buyer ensures transparency by requesting a detailed, itemized quote. This document should list the brand and model of all major components, including the PLC, motors, and sensors. It must also separate the machine price from shipping and installation fees.

Post time: Dec-12-2025