Maintaining product freshness is paramount in the snack industry. Consumers expect crisp, flavorful snacks with every purchase. A pillow packing machine directly addresses this need. It creates an optimal environment inside each package. This preserves the quality and taste of the product from the factory to the consumer's hands. By controlling the package atmosphere, businesses can significantly reduce spoilage and extend shelf life.

Create Airtight Seals to Lock in Freshness

An airtight seal is the first line of defense against spoilage. It prevents external contaminants like moisture, oxygen, and bacteria from entering the package. The SOONTRUE PILLOW / GUSSETED / CHAINED BAGGER excels at creating strong, reliable seals. This ensures that the snack's original texture and flavor remain intact. Secure sealing locks in freshness, guaranteeing a high-quality consumer experience and protecting brand reputation.

Extend Shelf Life with Gas Flushing

Gas flushing, also known as Modified Atmosphere Packaging (MAP), is a crucial technique for extending shelf life. This process involves replacing the air inside a package with a specific gas, typically nitrogen.

·Nitrogen's Role: Nitrogen is an inert gas. It displaces oxygen, which is a primary cause of food degradation.

·Benefits: Removing oxygen slows down oxidation and inhibits the growth of aerobic microorganisms. This process keeps snacks like chips and nuts from becoming stale or rancid.

The SOONTRUE bagger can integrate a nitrogen filling device. This feature allows businesses to leverage gas flushing, significantly prolonging product freshness and marketability.

Solve Freshness and Shelf-Life Challenges

Maintaining product freshness is paramount in the snack industry. Consumers expect crisp, flavorful snacks with every purchase. A pillow packing machine directly addresses this need. It creates an optimal environment inside each package. This preserves the quality and taste of the product from the factory to the consumer's hands. By controlling the package atmosphere, businesses can significantly reduce spoilage and extend shelf life.

Create Airtight Seals to Lock in Freshness

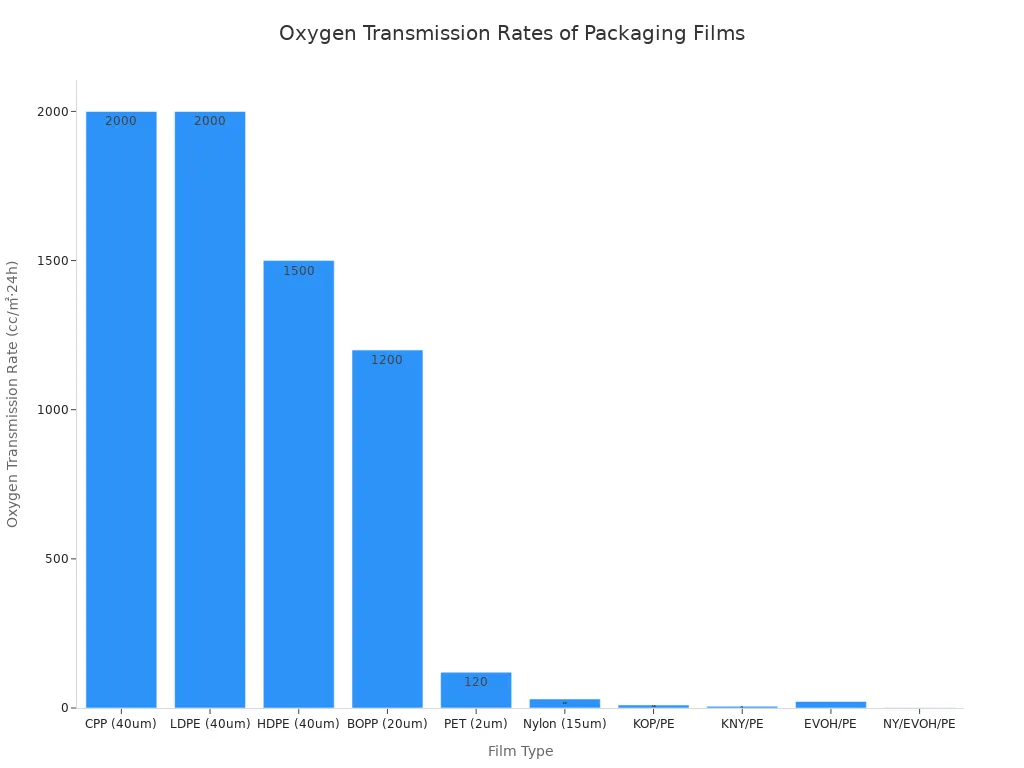

An airtight seal is the first line of defense against spoilage. It prevents external contaminants like moisture, oxygen, and bacteria from entering the package. The choice of packaging film is also critical. Different materials have varying levels of protection, measured by their Oxygen Transmission Rate (OTR). A lower OTR indicates a better barrier against oxygen. For example, standard films like Polypropylene (PP) offer a moderate barrier, while high-barrier films like EVOH or Metallized PET provide superior protection for sensitive products. Selecting the right film ensures the packaging effectively preserves the snack's quality.

Extend Shelf Life with Gas Flushing

Gas flushing, also known as Modified Atmosphere Packaging (MAP), is a crucial technique for extending shelf life. This process involves replacing the air inside a package with a specific gas, typically nitrogen. Nitrogen is the industry standard for snacks like potato chips and nuts.

·Prevents Oxidation: Nitrogen displaces oxygen, which prevents the fats and oils in snacks from oxidizing and becoming rancid.

·Preserves Texture: It helps maintain the intended crispiness and crunchiness of products like chips and cookies.

·Protects Structure: The gas provides a gentle cushion, preventing delicate items from being crushed during shipping.

A Pillow Packing Machine equipped with a nitrogen filling device makes this process seamless.

Nitrogen vs. Vacuum PackagingWhile vacuum packaging also removes oxygen, it can damage fragile snacks. Nitrogen packaging is a gentler method. It preserves the product's structure and texture, making it the excellent choice for delicate snack foods.

Eliminate Product Breakage and Damage

Product integrity is a non-negotiable aspect of the snack food industry. Consumers expect whole chips, intact cookies, and uncrushed crackers. Broken products lead to customer dissatisfaction and financial loss. A pillow packing machine provides a two-pronged defense against breakage. It uses both the package design and its mechanical operation to protect delicate items from the production line to the retail shelf.

Use the "Pillow" Effect for Cushioning

The most visible form of protection comes from the package itself. The term "pillow pack" refers to the bag's inflated, pillow-like appearance. This is not just for show; it is a functional design feature. During the packaging process, the bag is filled with nitrogen or air. This gas creates a soft cushion around the snacks.

This cushion serves a vital purpose. It absorbs shocks and vibrations that occur during shipping and handling. Industry reports confirm that this type of protective packaging is crucial for preventing damage to fragile goods. Snack manufacturers specifically rely on this gas-filled cushion to minimize breakage. The effectiveness of this method is well-documented, with some industries reporting damage claim reductions of up to 25% after adopting similar inflatable packaging solutions. This air buffer ensures that delicate products like potato chips and pretzels arrive at their destination intact.

Minimize Damage with Gentle Handling

Protection extends beyond the final package. The packaging process itself must be gentle to avoid damaging products before they are even sealed. Modern machines are engineered for this purpose.

A Pillow Packing Machine combines the external protection of a cushioned bag with the internal protection of a gentle mechanical process. This dual approach ensures maximum product integrity.

Many systems utilize a vertical, gravity-assisted design. Products drop gently into the bag, minimizing the side pressure and impact that can cause breakage. Key features that ensure gentle handling include:

·Servo-Driven Systems: These advanced motors provide smooth, precise, and controlled movements. They eliminate the abrupt motions and vibrations that can shatter fragile snacks.

·Controlled Filling: Specialized mechanisms slow down the filling process for delicate items. This reduces the force of impact as products enter the bag.

·Customizable Components: The machine can adapt to different product shapes and sizes. This prevents jams and ensures that items like cookies or irregularly shaped snacks are handled without damage.

This focus on gentle mechanics is essential for preserving the quality and appearance of the final product.

Boost Production Speed with a Pillow Packing Machine

In a competitive market, production speed directly impacts profitability. Manual or semi-automated packaging lines often create bottlenecks, limiting a company's ability to scale. A Pillow Packing Machine transforms this process by introducing high-speed automation, enabling businesses to meet growing demand efficiently. This shift from manual labor to automated precision is a strategic move for any snack manufacturer looking to enhance operational capacity.

Automate the Entire Bagging Process

A fully automated system handles every step of the packaging cycle with minimal human intervention. This integration creates a seamless and continuous workflow from product weighing to final sealing. A single machine can achieve remarkable speeds, with some models producing between 40 and 300 bags per minute. This level of automation is made possible by integrating various ancillary systems:

·Multi-head Weighers: Accurately measure and dispense the correct amount of product into each bag.

·Metal Detectors & Check Weighers: Ensure product safety and weight consistency before sealing.

·Nitrogen Gas Flushing: Injects nitrogen to preserve freshness and protect the product.

This cohesive process eliminates the delays and inconsistencies common in manual operations, ensuring a rapid and reliable packaging output.

Increase Output and Lower Labor Costs

Automating the packaging line delivers a significant return on investment by boosting throughput and reducing operational expenses. Companies that adopt automated solutions often report a throughput increase of up to 40%. This dramatic rise in productivity allows businesses to fulfill larger orders and expand their market reach without a proportional increase in facility size.

By reallocating employees from repetitive packaging tasks to more value-added roles, businesses can optimize their workforce and reduce the costs associated with manual labor. This efficiency gain is a key advantage of automation.

The speed difference is clear when comparing machine types. While semi-automatic systems rely on operators for tasks like product loading, fully automatic machines perform multiple operations simultaneously. This capability not only accelerates production but also lowers the per-unit cost, making the entire operation more profitable.

Enhance Brand Appeal and Consistency

Packaging is often the first interaction a consumer has with a product. It serves as a silent salesperson on the retail shelf. A pillow packing machine helps businesses capitalize on this opportunity. It produces packaging that is not only protective but also visually appealing and consistent, strengthening brand identity and attracting customers.

Achieve Professional and Uniform Packaging

Consistent branding across a product line is crucial for building brand recognition and consumer trust. Customers can easily identify their favorite brands when the packaging maintains a uniform look. The SOONTRUE PILLOW / GUSSETED / CHAINED BAGGER excels at creating this uniformity. It ensures every bag has the same dimensions, seal quality, and professional finish. This consistency reinforces a brand's reliability and value.

The machine achieves this precision through advanced mechanical synchronization.

- A forming collar shapes the flat film into a perfect tube.

- The system precisely times the product drop into the tube.

- This synchronized movement between the film and the product ensures each bag is identical, preventing inconsistencies and jams.

Optional features like a Euro slot hole punching device further enhance the professional appearance for retail display.

Ensure Vibrant Branding with Printed Film

Vibrant graphics transform a simple bag into a powerful branding tool. Using pre-printed film allows companies to display bold logos, enticing product images, and essential information. The quality of this printing directly impacts consumer perception. Rotogravure printing is a superior method for this purpose. It produces high-resolution images with rich color saturation and fine detail, allowing for full-bleed designs that create a premium look.

A pillow packing machine ensures this beautiful artwork is perfectly presented on every package.

The machine uses intelligent vision technology, including photoelectric registration sensors. These sensors detect printed marks on the film, guaranteeing millimeter-accurate cutting and flawless pattern alignment. This process minimizes material waste and ensures every bag perfectly reflects the brand's design.

This precision technology makes certain that the investment in high-quality printed film results in a flawless and professional final product.

A Pillow Packing Machine offers a comprehensive solution to the snack industry's biggest challenges. It directly addresses freshness, product protection, production speed, and brand consistency. Automating the process reduces labor costs and minimizes material waste. Enhanced sealing and gas flushing features also decrease product returns by extending shelf life.

While the initial purchase requires investment, the long-term financial benefits from increased efficiency and reduced waste make it a sound strategic decision for any growing snack business.

FAQ

What types of snacks can a pillow packing machine handle?

A pillow packing machine packages a wide range of snacks. It effectively handles delicate items like chips and pretzels and durable products like nuts and candies. The machine's gentle process protects product integrity, ensuring quality from the factory to the consumer.

Can one machine produce different types of bags?

Yes, versatile models like the SOONTRUE PILLOW / GUSSETED / CHAINED BAGGER produce multiple bag styles. A single machine can create:

- Standard pillow bags

- Gusseted bags for more volume

- Chained bags for multi-packs

This adaptability allows businesses to meet diverse packaging needs efficiently.

Why are snack bags filled with "air"?

Snack bags are not filled with air but with nitrogen gas. This process, called gas flushing, creates a protective cushion to prevent breakage. It also displaces oxygen, which keeps snacks fresh and extends their shelf life, preventing them from becoming stale.

How does this machine improve production speed?

This machine automates the entire bagging process from weighing to sealing. It operates continuously at high speeds, eliminating manual bottlenecks. This automation significantly increases production output while reducing the reliance on manual labor, boosting overall operational efficiency for the business.

Post time: Jan-08-2026