Top China Manufacturer of Bopp Slitting Machines for Optimal Performance

As a leading manufacturer of Bopp Slitting Machines in China, I understand the unique needs of businesses like yours that strive for efficiency and quality. Our Bopp Slitting Machine is designed to enhance your production line, offering precision slitting capabilities for BOPP films that ensure consistent results. With a focus on durability and performance, this machine empowers you to increase your output while maintaining the highest standards of quality. I've seen firsthand how our customers appreciate the user-friendly interface, making operations smooth even for new employees. Plus, we offer tailored solutions to fit your specific requirements, whether you're in packaging or label production. By choosing our Bopp Slitting Machine, you're not just buying equipment; you're investing in reliability and innovation that will drive your business forward in the competitive market. Let's work together to elevate your production capabilities and achieve your business goals!

Bopp Slitting Machine Ahead of the Curve Custom Solutions,

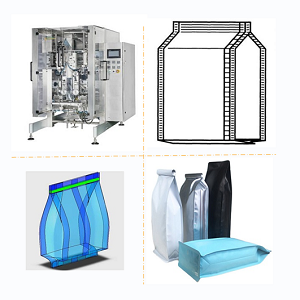

In today’s fast-evolving manufacturing landscape, staying competitive requires innovative solutions and advanced machinery. The Bopp slitting machine stands out as a pivotal investment for businesses looking to enhance production efficiency and deliver superior quality. Designed to meet the unique demands of various industries, this high-performance equipment offers custom solutions that align perfectly with your specific needs. Whether you’re cutting BOPP films for packaging or other applications, these machines provide precision and reliability, ensuring minimal waste and optimal throughput. Adapting to market trends is crucial for procurement professionals. With features such as adjustable cutting widths and speeds, these slitting machines can cater to diverse product specifications while maintaining consistency in quality. This adaptability ensures that you can swiftly respond to changing customer demands without compromising on output. The integration of advanced control systems allows for real-time monitoring and adjustments, providing users with complete command over the slitting process. Investing in a Bopp slitting machine not only streamlines production but also enhances the durability of the products manufactured. As businesses seek to differentiate themselves from competitors, utilizing cutting-edge equipment that guarantees excellence becomes imperative. This state-of-the-art technology is not just about keeping pace with the industry, but about setting new benchmarks in quality and efficiency, positioning your business for sustained success in a global market. Embrace the future of production with tailored solutions that empower your operations and elevate your brand.

Bopp Slitting Machine Ahead of the Curve Custom Solutions

| Feature | Specification | Benefits |

|---|---|---|

| Slitting Width | 1000 mm - 1800 mm | High versatility for different film sizes |

| Slitting Speed | Up to 300 m/min | Increased productivity and efficiency |

| Material Types | BOPP, PET, CPP | Compatibility with a wide range of materials |

| Control System | PLC-based control | User-friendly operation and monitoring |

| Safety Features | Emergency stop, safety guards | Enhanced safety for operators |

| Dimension (L x W x H) | 4000 mm x 1800 mm x 1500 mm | Compact design for better space management |

| Weight | 1500 kg | Stable performance during operation |

Related Products