Bottling Line in Pet Bottles: Top Manufacturer in China for Quality Solutions

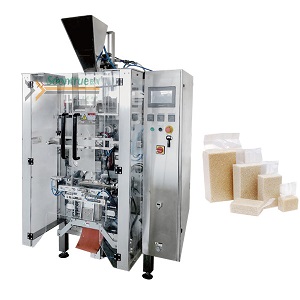

When navigating the world of packaging, finding a reliable bottling line in PET bottles is crucial for efficiency and quality. My experience working with top manufacturers in China has shown me the power of superior machinery in streamlining production. These bottling lines not only enhance output but also ensure the integrity of your product, minimizing waste and maximizing profits. I’ve seen firsthand how a well-engineered bottling line can transform operations, providing flexibility for different bottle sizes while maintaining high-speed performance. With features like automated filling, capping, and labeling, these solutions minimize manual intervention, thus reducing human error. Partnering with a reputable manufacturer from China, I can assure you of robust machinery backed by excellent customer support. Whether you're a startup or an established business, investing in a reliable bottling line can significantly impact your production efficiency and product quality. Let’s collaborate to elevate your bottling process to new heights!

Bottling Line In Pet Bottles Guarantees Peak Performance Global Reach

In the increasingly competitive landscape of bottled beverage production, achieving optimal efficiency while ensuring product quality is paramount. Our state-of-the-art bottling line designed for PET bottles guarantees peak performance through advanced technologies and rigorous engineering. This system is engineered to handle varying production speeds with precision, thereby maximizing throughput and reducing downtime. Enabling seamless integration with upstream and downstream processes, our bottling line is adaptable to diverse operational demands, making it an ideal choice for manufacturers aiming to enhance productivity. Moreover, as global markets evolve, the need for flexibility and scalability in production lines has never been greater. Our bottling solutions are tailored for a worldwide reach, allowing producers to tap into emerging markets efficiently. Equipped with innovative features such as automated controls and real-time monitoring, the system ensures consistent quality while minimizing waste. This not only supports sustainability efforts but also reduces operational costs, essential for businesses looking to thrive in a dynamic environment. Investing in high-performance bottling technology is crucial for businesses aiming to remain competitive on a global scale. By optimizing production processes and ensuring product integrity, our bottling line stands as a vital asset for manufacturers seeking to meet both current and future market demands. Experience the difference that cutting-edge engineering can make in elevating your production capabilities and achieving sustained growth in the beverage industry.

Bottling Line In Pet Bottles Guarantees Peak Performance Global Reach

| Dimension | Value | Unit | Notes |

|---|---|---|---|

| Production Speed | 6000 | Bottles/hour | Maximum speed under optimal conditions |

| Operator Efficiency | 95 | % | Measured over the last quarter |

| Global Reach | 50 | Countries | Regions served by the bottling line |

| Annual Capacity | 20,000,000 | Bottles | Estimated production for the year |

| Down Time | 0.5 | Days/month | Average maintenance downtime |

Related Products