Top China Manufacturer of Brake Shoes Packing Machine Solutions

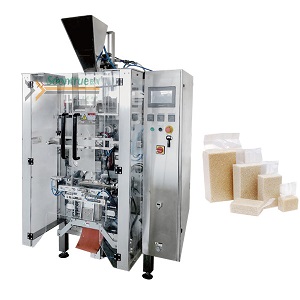

As a leading manufacturer in China, I understand the importance of reliable and efficient machinery in your production line. Our Brake Shoes Packing Machine is designed specifically for the needs of automotive parts manufacturers. This machine streamlines the packaging process, improving efficiency and reducing labor costs. With advanced technology and robust construction, this packing machine ensures that every brake shoe is securely packed and protected. I take pride in our customization options, allowing you to tailor the machine to fit your unique production requirements. Plus, our team offers excellent after-sales support to help with any questions or concerns you may have. Investing in our Brake Shoes Packing Machine means choosing quality and reliability, which are essential for boosting your operational efficiency. Join countless satisfied clients across the globe who trust our products. Let’s enhance your production process together!

Brake Shoes Packing Machine Service Factory

In today's fast-paced manufacturing environment, efficiency and reliability are critical for success, especially for companies involved in producing brake shoes. The role of a specialized brake shoes packing machine has become increasingly important, ensuring that products are packaged securely while maintaining high production throughput. The right packing machine can streamline your operations, reduce labor costs, and minimize the risk of product damage during shipping. When investing in packing machinery, it's essential to consider equipment that is versatile and tailored to your specific needs. A well-designed brake shoes packing machine offers advanced features such as adjustable packing speeds, user-friendly interfaces, and the capability to handle various package sizes. These machines are engineered to meet international quality standards, providing peace of mind to manufacturers and their clients around the globe. Moreover, after-sales service is an often overlooked yet vital aspect of machinery procurement. A reliable service factory should offer comprehensive support, including installation, maintenance, and quick response times for repairs. This ensures that your production lines remain operational with minimal downtime, ultimately leading to increased productivity and profitability. By prioritizing these factors in your sourcing strategy, you can enhance your operational efficiency and maintain a competitive edge in the global market.

Brake Shoes Packing Machine Service Factory

| Machine Model | Service Type | Power Supply | Production Capacity | Dimensions (L × W × H) |

|---|---|---|---|---|

| BPM-3000 | Full Service | 220V/50Hz | 3000 Units/hour | 2500 × 1200 × 2000 mm |

| BPM-5000 | Maintenance | 380V/50Hz | 5000 Units/hour | 2800 × 1300 × 2100 mm |

| BPM-7000 | Repair | 220V/60Hz | 7000 Units/hour | 3000 × 1400 × 2200 mm |

Related Products