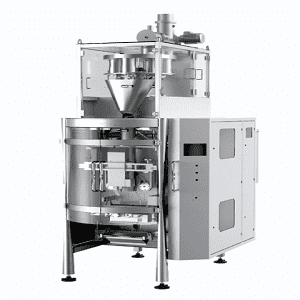

Wholesale Capping Machine Pack Automatic from Trusted Manufacturers

Are you in the market for a reliable capping machine pack automatic? I’ve found that this equipment is essential for businesses looking to streamline their packaging process. With its efficient operation, wholesale prices, and tailored solutions, it’s perfect for manufacturers like me who care about quality and speed. This automatic capping machine is designed to handle various bottle sizes and materials, ensuring a tight seal every time, which enhances product longevity. When I was sourcing for machines, I prioritized finding one that minimizes downtime and maximizes productivity. This model does just that! Plus, the ease of use is a major plus for my team, allowing us to focus on growing our business instead of dealing with complicated machinery. If you’re a manufacturer seeking an affordable solution without compromising on quality, I highly recommend considering this automatic capping machine for your production needs. It's been a game changer for our operations.

Capping Machine Pack Automatic Application in 2025

As we venture into 2025, the landscape of packaging technology continues to evolve, with automatic capping machines leading the charge in enhancing production efficiency and product integrity. In the fast-paced world of manufacturing and packaging, these machines have become indispensable for companies seeking to streamline their operations while maintaining the highest standards of quality. Automatic capping machines are designed to handle various cap types and sizes seamlessly, ensuring that products are securely sealed while minimizing the risk of contamination. The benefits of incorporating automatic capping machines into production lines are manifold. Firstly, they significantly reduce labor costs by automating a task that traditionally required manual intervention. This not only frees up human resources for more complex tasks but also minimizes the possibility of human error, ultimately leading to a more reliable sealing process. Additionally, with advancements in technology, these machines can be easily integrated with existing production lines, providing flexibility and scalability that modern manufacturers require. As global supply chains continue to adapt to shifting demands and increased automation, investing in innovative packaging solutions like automatic capping machines is critical for maintaining competitive advantage. With their ability to enhance efficiency, reduce costs, and ensure consistent quality, businesses are well-positioned to meet the growing expectations of consumers in 2025 and beyond. Embracing this technology not only aligns with current industry trends but also paves the way for sustainable growth in the ever-evolving marketplace.

Capping Machine Pack Automatic Application in 2025

| Application Area | Machine Type | Capacity (Bottles/Min) | Energy Consumption (kW) | Automation Level | Key Features |

|---|---|---|---|---|---|

| Beverage Industry | Rotary Capping Machine | 120 | 5 | High Automation | Smart Sensors, Easy Maintenance |

| Pharmaceuticals | Inline Capping Machine | 80 | 3 | Medium Automation | Interchangeable Parts, Safety Features |

| Cosmetics | Automatic Capping Machine | 60 | 4 | Fully Automated | Versatile, Quick Changeover |

| Food Industry | Semi-Automatic Capping Machine | 90 | 3.5 | Low Automation | Manual Override, Compact Design |

| Chemicals | Custom Capping Machine | 75 | 6 | High Automation | Corrosion-Resistant, High Durability |

Related Products