Top China Manufacturer of Cosmetic Box Cartoning Machines

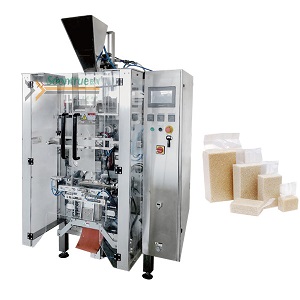

As a leading manufacturer in China, I understand the importance of efficient packaging solutions for cosmetic products. Our Cosmetic Box Cartoning Machine is designed to streamline your packaging process, enhancing productivity while maintaining the quality of your cosmetics. This machine efficiently forms and seals boxes, catering to various sizes and styles, ensuring your products are perfectly displayed and protected. With user-friendly controls and precise technology, it simplifies the operation, reducing labor costs and minimizing errors. I’ve seen firsthand how this machine can improve workflow and save time in the busy production environment. It’s built from robust materials, promising durability and reliability for your long-term needs. Partnering with us means you’re not just getting a machine, but a commitment to quality and excellence in packaging. Let’s elevate your cosmetic packaging game together—trust us to deliver the perfect cartoning solution for your business!

Cosmetic Box Cartoning Machine Supplies the World\u2019s Top Brands Service Backed by Expertise

In the rapidly evolving world of cosmetics, packaging not only serves a functional purpose but also plays a crucial role in brand identity and consumer experience. The demand for high-quality packaging solutions is increasing, and manufacturers are seeking advanced technologies to meet these needs. Enter the cutting-edge cartoning machine, a pivotal innovation that streamlines production processes while ensuring precision and efficiency. These machines cater to various cosmetic products, providing seamless integration into existing production lines and delivering exceptional quality that resonates with brands striving for excellence. Leveraging years of expertise, these cartoning machines are engineered to support the world's top cosmetics brands, offering tailored solutions that prioritize both flexibility and scalability. As global market trends shift toward sustainability and eco-friendliness, modern machines are designed with energy efficiency and reduced material waste in mind. This transition not only aligns with consumer values but also enhances operational efficiency, empowering brands to maintain competitiveness in a crowded market. By investing in state-of-the-art cartoning technology, cosmetics manufacturers can elevate their packaging game, ensuring that every product leaving their facility is encased in a visually appealing, secure, and sustainable package. The right machine can robustly reinforce brand messaging while adapting to the diverse needs of the global market, ultimately delivering a powerful impact on customer satisfaction and brand loyalty.

Cosmetic Box Cartoning Machine Supplies the World’s Top Brands Service Backed by Expertise

| Feature | Description | Benefits | Application |

|---|---|---|---|

| High Speed | Capable of processing up to 30 boxes per minute. | Increases production efficiency and reduces labor costs. | Cosmetic packaging lines. |

| Versatile Design | Compatible with various box sizes and styles. | Flexibility to accommodate diverse product lines. | Skincare, makeup, and personal care products. |

| User-friendly Interface | Intuitive controls for easy operation. | Reduces training time for operators. | Manufacturing facilities. |

| Durability | Constructed from high-quality materials for longevity. | Low maintenance costs and extended service life. | Long-term production environments. |

| Automated Operation | Fully automated system to minimize manual labor. | Improves productivity and consistency. | Production lines. |

Related Products