High Quality Rice Packing Machine Manufacturer in China - Top Solutions

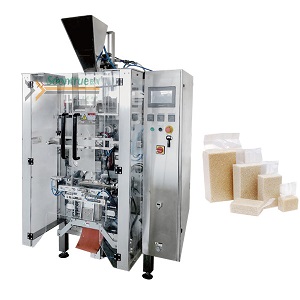

If you’re in the market for a high-quality rice packing machine, I’ve got just the solution for you. Our machines, proudly manufactured in China, guarantee durability and efficiency, making them perfect for businesses like yours that strive for excellence. With our state-of-the-art technology, you can automate your packing process, reducing labor costs and minimizing waste. I’ve seen firsthand how our machines can boost productivity, ensuring that every grain is packed perfectly. Plus, with customizable options, you can tailor the specifications to meet your unique business needs. Trust me, investing in our rice packing machine means investing in quality and reliability. Let’s take your packaging operation to the next level together—because a good machine is key to a successful business!

High Quality Rice Packing Machine Supplier Supplies the World\u2019s Top Brands

In today’s competitive marketplace, the demand for high-quality packaging solutions is paramount, especially in the food sector. For rice producers seeking to enhance their brand's reputation, partnering with a dependable packing machine supplier can significantly improve product presentation and prolong shelf life. Advanced rice packing machines are designed to cater to diverse packaging requirements, whether in terms of style, volume, or sustainability. They not only ensure precision in filling and sealing but also incorporate innovative features that enhance efficiency and reduce waste. Global brands recognize the importance of investing in state-of-the-art packing technology, which directly translates to consumer satisfaction and brand loyalty. Opting for high-caliber packing machinery allows businesses to adapt quickly to market trends, such as eco-friendly packaging, by integrating biodegradable materials. Furthermore, reliable suppliers ensure that their machines comply with international standards and offer ongoing support, ensuring businesses can keep up with production demands while minimizing downtime. As the rice market continues to expand, international procurement specialists are actively seeking suppliers capable of delivering quality equipment tailored to their specific needs. Choosing a supplier that prioritizes quality and innovation can make all the difference in maintaining a competitive edge in the global rice industry.

High Quality Rice Packing Machine Supplier Supplies the World’s Top Brands

| Machine Model | Capacity (kg/h) | Power (kW) | Dimension (mm) | Weight (kg) |

|---|---|---|---|---|

| Model A | 1500 | 15 | 2000 x 800 x 1200 | 800 |

| Model B | 2000 | 18 | 2200 x 900 x 1300 | 900 |

| Model C | 2500 | 20 | 2500 x 1000 x 1400 | 1000 |

| Model D | 3000 | 25 | 2700 x 1100 x 1500 | 1200 |

Related Products