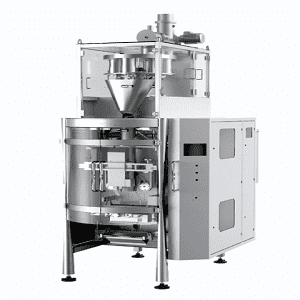

Wholesale Liquid Sachet Machine from Leading Manufacturers

When I think about efficiency in packaging, the Liquid Sachet Machine comes to mind as a game-changer for businesses like yours. Tailored for wholesale requirements, this machine allows manufacturers to streamline their operations, ensuring that each sachet is filled accurately and with precision. The ability to pack various liquids into convenient sachets not only saves space but also enhances your product’s appeal to customers. I've seen many manufacturers benefit from investing in this advanced technology, as it boosts productivity while reducing waste. Plus, the machine’s compact design fits seamlessly into any production line. Whether you’re in food, pharmaceuticals, or other industries, the Liquid Sachet Machine caters to your unique needs, making it an ideal choice for B2B purchasers. Don't let inefficient packaging hold you back—consider the Liquid Sachet Machine for a smarter, more effective solution to your packaging needs.

Liquid Sachet Machine Application Factory

In the fast-paced world of manufacturing, efficiency and precision are crucial. Liquid sachet machines have emerged as vital tools for a variety of industries, including food and beverage, pharmaceuticals, and personal care products. These machines streamline the packaging process, ensuring high-speed production while maintaining strict quality control standards. The ability to package liquids into convenient sachets not only enhances product appeal but also improves shelf life and reduces waste, making it an essential solution for global buyers seeking to stay ahead in competitive markets. Investing in a liquid sachet machine allows manufacturers to benefit from advanced technology that offers customizable features, such as adjustable fill volumes and sealing options. This flexibility caters to diverse product needs and enhances operational efficiency. Moreover, the demand for eco-friendly packaging solutions has led to innovations in the design of these machines, enabling the use of biodegradable materials that align with sustainable practices. By choosing cutting-edge liquid sachet machines, companies can not only optimize their production processes but also demonstrate a commitment to environmental stewardship. As global trade continues to expand, the importance of reliable and efficient packaging solutions cannot be overstated. The rise in e-commerce and consumer demand for convenience-driven products further emphasizes the need for high-quality sachet machines that deliver consistent results. Buyers across the world are looking for reputable suppliers who can provide robust, state-of-the-art machinery that meets their unique operational requirements. Prioritizing efficiency, sustainability, and versatility is key to successfully navigating the complexities of today’s packaging landscape.

Liquid Sachet Machine Application Factory

| Application Area | Machine Type | Production Speed (units/min) | Sachet Volume (ml) | Material Compatibility | Power Supply (V) |

|---|---|---|---|---|---|

| Food Industry | Automatic Sachet | 50 | 5-50 | Plastic, Foil | 220 |

| Cosmetics | Semi-automatic Sachet | 30 | 10-100 | HDPE, LDPE | 110 |

| Pharmaceutical | Fully Automatic Sachet | 100 | 1-50 | Aluminum, PET | 380 |

| Chemical | Vertical Form Fill Seal | 60 | 20-500 | Plastic, Composite | 230 |

Related Products