Top China Manufacturer of Packaging Machines for Chocolate

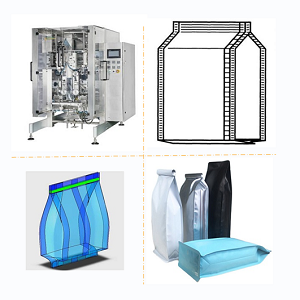

When it comes to packaging machines for chocolate, I've seen firsthand how crucial efficiency and reliability are for businesses in the confectionery industry. That's why I’m excited to share my experience with top-tier manufacturers in China who provide cutting-edge solutions tailored for your needs. These machines not only ensure perfect sealing and protection of your chocolate products but also boost your production speed, making your operations more profitable. With customizable options available, these packaging machines can handle various chocolate forms—bars, truffles, or even bulk packaging. Plus, the technology used is both user-friendly and easy to maintain, which means less downtime and more output for you. If you’re aiming to elevate your packaging process and keep your chocolate fresh and appealing, I highly recommend exploring the range of offerings from reputable Chinese manufacturers. You won't be disappointed in the quality and performance!

Packaging Machine For Chocolate Industry Giant Global Reach

In today's competitive chocolate industry, packaging plays a pivotal role in maintaining product quality and shelf appeal. Among the essential equipment that ensures seamless production and packaging processes are advanced packaging machines tailored for chocolate products. These machines not only enhance efficiency but also mitigate the risks associated with contamination and spoilage, ultimately contributing to customer satisfaction. When it comes to global sourcing, manufacturers are increasingly seeking innovative, reliable, and versatile packaging solutions. Advanced packaging machines can accommodate a variety of chocolate forms, from solid bars to decorative truffles, tailored to the diverse needs of international markets. By investing in state-of-the-art technology, manufacturers can ensure their packaging processes meet the highest industry standards, thus appealing to a broader audience. Moreover, sustainability has emerged as a crucial factor for global buyers. Many packaging machines are now designed with eco-friendly materials and technologies, help producers reduce their carbon footprint while still ensuring that products reach consumers in pristine condition. The integration of automation and intelligent controls further enhances operational efficiency, allowing chocolate producers to respond swiftly to market demands while maintaining product integrity.

Packaging Machine For Chocolate Industry Giant Global Reach

| Machine Model | Production Speed (units/hour) | Bag Size (mm) | Material Type | Energy Consumption (kW) | Country of Manufacturing |

|---|---|---|---|---|---|

| XG-100A | 300 | 50x100 | Plastic | 5.5 | Germany |

| CHoco-Pack V2 | 250 | 75x125 | Paper | 4.0 | Italy |

| SweetPack 4000 | 400 | 60x110 | Foil | 6.0 | USA |

| PackMaster 300 | 200 | 55x90 | Composite | 5.0 | Switzerland |

Related Products

.jpg)