- Getting started

- Pillow Packaging Machine Food Machinery Fried Rice Instant Noodle Fresh Vegetable Potato Snack Food Packing Machine

Wholesale Pillow Packaging Machine for Fried Rice, Noodles & Snacks

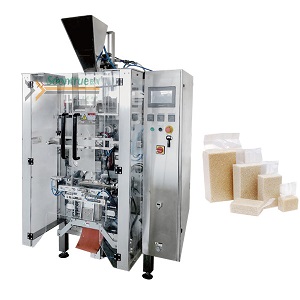

As a trusted manufacturer in the food machinery industry, I’ve seen the demands of the market change. Our Pillow Packaging Machine is specially designed to meet the needs of businesses looking to efficiently pack fried rice, instant noodles, fresh vegetables, and potato snacks. With my hands-on experience, I know that quality is key when it comes to food packaging, and our machines offer robust performance tailored for wholesale buyers. This advanced packing solution not only enhances the presentation of your products but also ensures maximum freshness and safety during storage and transit. With adjustable settings for various food types, it's versatile and easy to operate. I take pride in providing reliable equipment that can help scale your business effectively. If you’re on the lookout for a dependable partner in food packing machinery, let’s connect and explore how we can elevate your packaging process together.

Pillow Packaging Machine Food Machinery Fried Rice Instant Noodle Fresh Vegetable Potato Snack Food Packing Machine Factory For the Current Year

In the fast-paced world of food production, efficiency and quality are paramount. Our latest innovation, the Pillow Packaging Machine, is designed specifically to meet the growing demands of the food industry, particularly for fried rice, instant noodles, fresh vegetables, and potato snacks. This state-of-the-art machine automates the packaging process, ensuring that your products are not only sealed securely but also maintain their freshness and appeal on the shelves. The machine’s adaptability to different food types makes it a versatile addition to any production line, offering your business the capability to enhance productivity and output without sacrificing quality. With a focus on reliability and performance, this packaging solution is equipped with advanced technology that provides precise control over the packaging process. This means you can achieve consistent bag sizes and weights, optimizing your materials and reducing waste. The user-friendly interface allows for easy operation and quick adjustments, reducing downtime and maximizing efficiency. As global consumers continue to seek convenient food options, our Pillow Packaging Machine can help you meet market demand while maintaining high standards of hygiene and safety. Investing in the right machinery is crucial for staying competitive in today's market. By incorporating the Pillow Packaging Machine into your production facility, you not only streamline your operations but also enhance the overall quality of your products. As the food industry evolves, having reliable and efficient packaging is key to ensuring customer satisfaction and brand loyalty. Embrace innovation and secure your place in the market with a packaging solution designed for the future of food production.

Pillow Packaging Machine Food Machinery Fried Rice Instant Noodle Fresh Vegetable Potato Snack Food Packing Machine Factory For the Current Year

| Machine Type | Application | Production Capacity (bags/min) | Power Consumption (kW) | Dimension (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Pillow Packing Machine | Instant Noodle | 30 | 2.5 | 1200 x 800 x 1850 | 500 |

| Multi-functional Packing Machine | Fried Rice | 40 | 3.0 | 1500 x 900 x 1900 | 600 |

| Vegetable Packing Machine | Fresh Vegetable | 25 | 2.2 | 1100 x 750 x 1800 | 450 |

| Snack Food Packing Machine | Potato Snack | 20 | 2.0 | 1150 x 850 x 1750 | 480 |

Related Products