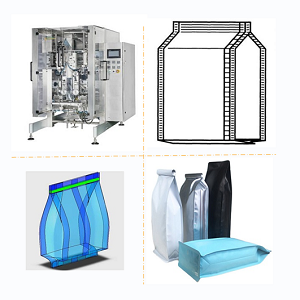

Polybag Packing Machine: Wholesale Options from Leading Manufacturers

When it comes to efficient packaging, my Polybag Packing Machine stands out in the market. Designed with manufacturers and wholesalers in mind, it streamlines your packing process, saving time and reducing labor costs. I’ve seen firsthand how this machine can enhance productivity, giving businesses like yours a competitive edge. With its user-friendly interface and robust construction, it's perfect for packaging a wide variety of products, ensuring each polybag is sealed securely. Whether you are looking to scale up operations or simply improve your current process, this machine meets the needs of diverse manufacturing environments. Investing in a Polybag Packing Machine means fewer production delays and more consistency in your output. I believe that by making this choice, you’ll not only optimize your workflow but also elevate the quality of your packaging. Let's chat about how this machine can work wonders for your business!

Polybag Packing Machine Industry Giant Where Innovation Meets 2025

In the dynamic landscape of packaging machinery, the polybag packing machine sector stands out as an emblem of innovation and efficiency. As we look forward to 2025, advancements in technology are set to revolutionize the way manufacturers approach packaging solutions. With a growing emphasis on sustainability, automation, and flexibility, companies are prioritizing intelligent machinery that not only enhances productivity but also reduces environmental impact. The demand for advanced packaging solutions is driven by various industries seeking to optimize their production processes. By integrating smart technologies, such as Artificial Intelligence and IoT, manufacturers can monitor performance in real-time, allowing for predictive maintenance and minimized downtime. This evolution in machine design meets the diverse needs of global buyers, ensuring that they receive cutting-edge solutions tailored to their specific requirements. Innovative polybag packing machines are also becoming vital in meeting international compliance standards, ensuring that packaging is both efficient and eco-friendly. As businesses around the world increasingly focus on responsible production practices, investing in these forward-thinking machines is essential for staying competitive in the marketplace. Embracing innovation in this sector will not only drive growth but will also align with the global movement towards sustainability in packaging.

Polybag Packing Machine Industry Giant Where Innovation Meets 2025

| Dimension | 2022 | 2023 | 2024 (Projected) | 2025 (Projected) |

|---|---|---|---|---|

| Global Market Size (in million USD) | 1500 | 1650 | 1800 | 2000 |

| Annual Growth Rate (%) | 8 | 10 | 9 | 12 |

| Number of Key Players | 25 | 27 | 30 | 32 |

| Emerging Technologies | Automation | AI Integration | IoT Solutions | Smart Packaging |

| Industry Challenges | Regulatory Compliance | Supply Chain Disruptions | High Material Costs | Sustainability Concerns |

Related Products