Wholesale Pre-Made Bag Packing Machine for Juice | Top Manufacturers

When I found the Pre-Made Bag Packing Machine for Juice, I knew it was a game-changer for our production line. This machine has been expertly designed for efficiency, allowing us to streamline our packaging process. With its user-friendly interface, we can easily adjust settings to accommodate different juice bags, ensuring we meet varying customer demands. As a manufacturer in the juice industry, quality and speed are crucial for us. This packing machine not only offers reliability but also reduces labor costs significantly. We've seen a marked increase in productivity since incorporating it into our operations. If you're in the market for wholesale options, I highly recommend exploring this pre-made bag packing machine. It's built to last and tailored for businesses like ours, enhancing our ability to deliver fresh juice to retailers quickly. Don't miss the chance to optimize your packaging process!

Pre-Made Bag Packing Machine For Juice Manufacturer Pioneers in the Field

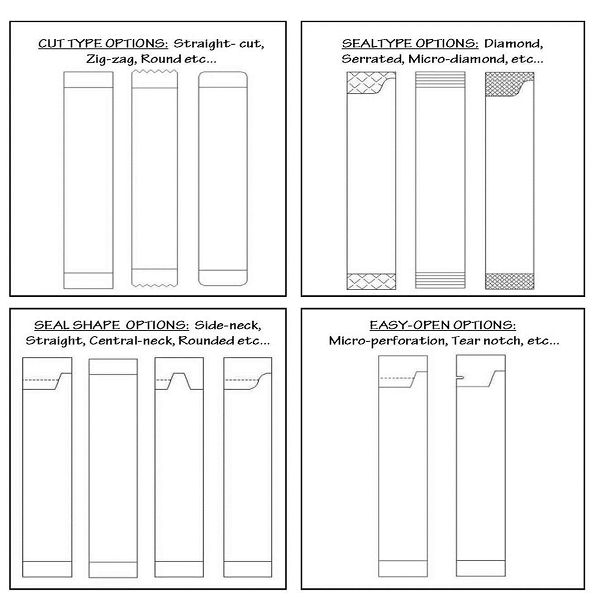

In the fast-paced world of juice manufacturing, the efficiency of production processes plays a pivotal role in staying ahead of the competition. One of the most significant advancements in this industry is the use of pre-made bag packing machines. These machines offer an innovative solution for juice manufacturers seeking to enhance their packaging operations. By streamlining the packing process, they minimize manual labor, reduce production time, and improve overall output quality. Pre-made bag packing machines are designed to accommodate various bag types and sizes, allowing juice manufacturers to efficiently package their products while maintaining freshness and quality. With features such as automated filling, sealing, and labeling, these machines ensure consistency and accuracy in every pack. Moreover, their user-friendly interfaces and advanced technology make them suitable for businesses of all sizes, from small enterprises to large-scale operations. Investing in pre-made bag packing machines not only elevates production efficiency but also aligns with the growing demand for sustainable packaging solutions. Many of these machines are equipped to handle eco-friendly materials, enabling manufacturers to contribute to environmental sustainability while meeting consumer preferences. By adopting such technologies, juice manufacturers can position themselves as pioneers in the field, ready to meet the challenges of a dynamic market and cater to the evolving needs of global consumers.

Pre-Made Bag Packing Machine For Juice Manufacturer Pioneers in the Field

| Feature | Description | Specifications | Applications |

|---|---|---|---|

| Automation Level | Fully automated system for efficient packing | PLC controlled with touch screen interface | Juice, smoothies, and liquid food products |

| Bag Type | Pre-made pouches of various sizes | Available in various materials such as polyethylene and laminates | Ideal for stand-up pouches and flat pouches |

| Packing Speed | High-speed operation to maximize productivity | Up to 50 bags per minute depending on size | Suitable for large production runs |

| Sealing Technology | Advanced heat sealing for reliable closure | Temperature control for optimal seal integrity | Ensures freshness and shelf-life extension |

| Maintenance | Low maintenance requirements with easy access points | User-friendly designs for quick servicing | Minimizes downtime and maintenance costs |

Related Products