Top China Manufacturer of Tea Stick Packaging Machinery Solutions

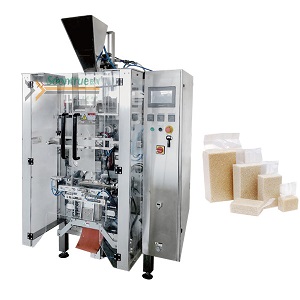

Are you in need of reliable Tea Stick Packaging Machinery? I understand how crucial efficient packaging is for your business, and I’m here to help. With years of experience in the industry, I work closely with a trusted manufacturer in China, offering state-of-the-art machinery specifically designed for tea stick packaging. This equipment not only streamlines your packaging process but also ensures that your product remains fresh and appealing. The machinery is engineered for high speed and precision, making it a perfect fit for both small and large-scale operations. Plus, working with a Chinese manufacturer allows us to provide competitive pricing without compromising on quality. Whether you’re looking to upgrade your existing setup or starting a new venture, my team can assist you in finding the right solution tailored to your needs. Let’s optimize your packaging efficiency together, ensuring your tea products stand out in the market!

Tea Stick Packaging Machinery Is The Best Ahead of the Curve

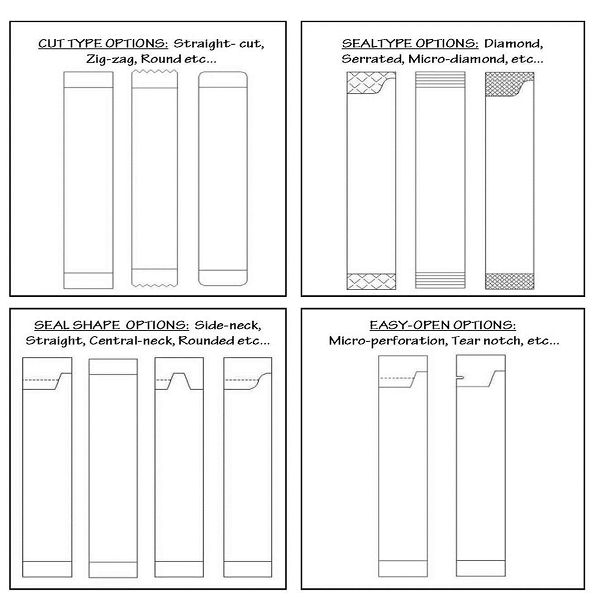

In today's fast-paced market, staying ahead of the curve is essential for businesses to thrive, especially in the competitive tea industry. The demand for convenient and innovative packaging solutions has never been higher, making tea stick packaging machinery a pivotal asset for manufacturers. With the rise of on-the-go lifestyles, consumers are increasingly looking for portable and user-friendly packaging that retains the freshness and quality of their beloved tea. By investing in advanced machinery, businesses can not only meet these demands but also enhance their production efficiency and overall product appeal. Tea stick packaging machinery boasts a range of benefits that align with modern consumer needs. The precise, automated processes ensure a consistent product while minimizing waste. This technology can accommodate various tea blends and adapt to different stick sizes, making it incredibly versatile. Furthermore, with the ability to implement environmentally friendly packaging materials, manufacturers can also appeal to the growing segment of eco-conscious consumers, contributing to sustainability efforts within the industry. Ultimately, choosing the right packaging machinery can be a game-changer for tea producers. It not only enhances operational productivity but also plays a crucial role in brand differentiation. Companies that embrace innovative solutions like tea stick packaging machinery will find themselves well-positioned to capitalize on emerging market trends and consumer preferences, ensuring long-term success in the global tea market.

Tea Stick Packaging Machinery Is The Best Ahead of the Curve

| Feature | Description | Benefits |

|---|---|---|

| Automation Level | Fully automated packaging process | Increases efficiency and reduces labor costs |

| Material Compatibility | Supports various biodegradable and eco-friendly materials | Aligns with sustainable packaging trends |

| Production Speed | Up to 100 packages per minute | Maximizes output and meets high demand |

| User Interface | Touchscreen control panel with intuitive navigation | Simplifies operation and reduces training time |

| Maintenance | Easy access for routine maintenance and repairs | Minimizes downtime and extends equipment lifespan |

Related Products