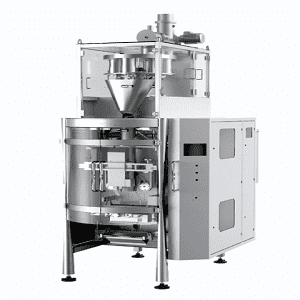

Top China Manufacturer of Vertical Medical Patch Packing Machines

As a manufacturer based in China, I'm excited to present our Vertical Medical Patch Packing Machine, designed specifically for the pharmaceutical and healthcare industries. This advanced machine ensures efficient, precise packaging of medical patches, enhancing productivity while maintaining high quality standards. With a user-friendly interface, you can easily adjust the settings to accommodate various patch sizes and materials. Our machine boasts a compact design, saving valuable floor space in your production area. The durable construction ensures longevity, giving you a reliable packing solution for years to come. I understand the importance of seamless operation in your manufacturing process, and our machine is engineered to minimize downtime and optimize workflow. Partnering with us means you get not just a product but a commitment to outstanding customer service and support. Choose our Vertical Medical Patch Packing Machine to elevate your packaging capabilities and delight your customers with quality and efficiency.

Vertical Medical Patch Packing Machine Industry Giant For the Current Year

The vertical medical patch packing machine industry is experiencing remarkable growth this year, driven by increasing demands for efficient and reliable packaging solutions within the healthcare sector. These machines are designed to meet the stringent requirements for packaging various medical patches, ensuring integrity, sterility, and ease of use for end consumers. With technological advancements, the latest models come equipped with innovative features, enhancing productivity while minimizing waste, making them indispensable tools for manufacturers seeking to optimize their production processes. Global procurement managers are particularly interested in the capabilities of these machines to accommodate diverse product sizes and types. The customization options available allow businesses to tailor their packaging solutions to meet specific market demands. Additionally, with an emphasis on sustainability, many leading manufacturers are integrating eco-friendly materials and processes into their operations, aligning with worldwide environmental initiatives. As the market evolves, investing in modern vertical packing equipment not only enhances operational efficiency but also positions companies to remain competitive in an increasingly dynamic landscape. In conclusion, the vertical medical patch packing machine industry stands at the forefront of innovation and efficiency, making it a significant focus for global buyers. As companies continue to navigate the complexities of production and distribution in the medical field, the ability to leverage cutting-edge packing technology will undoubtedly play a critical role in their success. With a commitment to quality and performance, businesses embracing these advancements will be well-equipped to meet the future challenges of the healthcare packaging landscape.

Vertical Medical Patch Packing Machine Industry Giant For the Current Year

| Machine Model | Production Speed (Units/Hour) | Application | Power Requirement (kW) | Dimensions (mm) |

|---|---|---|---|---|

| Model A | 500 | Transdermal Patches | 2.5 | 1200 x 800 x 1500 |

| Model B | 600 | Medical Dressings | 3.0 | 1300 x 900 x 1600 |

| Model C | 700 | Micro-Needle Patches | 2.8 | 1400 x 1000 x 1700 |

| Model D | 800 | Cosmetic Patches | 3.5 | 1500 x 1100 x 1800 |

Related Products