The ready-to-eat popcorn market shows significant growth, underscoring the need for efficient production. Selecting the right packing machine for popcorn is a critical business decision. Producers must evaluate several factors. These include the product type, like ready-to-eat or microwave popcorn. Packaging style, such as bags, pouches, or tubs, also guides the choice. Finally, production volume determines the necessary machine capacity. The main machine categories are Vertical Form Fill Seal (VFFS), Premade Pouch Fillers, Container Filling Lines, and Specialty Packers.

Popcorn Market at a GlanceThe industry's expansion is notable, with projections indicating substantial future growth.

Metric Value Market Size in 2024 USD 3.28 Billion Projected Market Size in 2032 USD 5.19 Billion CAGR (2025-2032) 5.91%

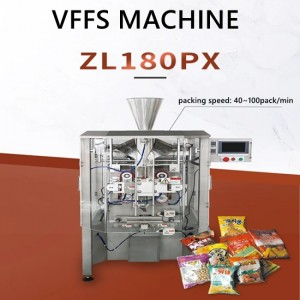

Vertical Form Fill Seal (VFFS) Machines for High-Volume Bagging

What It Is

Vertical Form Fill Seal (VFFS) machines are automated systems that create bags from a flat roll of film, fill them with product, and seal them shut in a continuous vertical motion. This type of packing machine for popcorn is a cornerstone of high-volume production. VFFS machinery is often the least expensive option compared to other automated packers, making it an accessible entry point for growing businesses. These systems operate at impressive speeds, with typical outputs ranging from 60 to 120 bags per minute. The machines use various film materials, including Polyethylene (PE), Polypropylene (PP), and composite films, which can incorporate an aluminum layer for enhanced barrier properties.

How It Works

The VFFS process is a highly efficient, automated sequence. A multi-head weigher, integrated at the top of the machine, ensures precise portioning of the popcorn, which is crucial for controlling costs and maintaining consistency. The machine then executes several steps automatically:

1.Bag Forming: The machine pulls the flat film over a forming tube, shaping it into a vertical tube. It then creates the bottom and vertical seals.

2.Filling: The pre-weighed popcorn from the multi-head weigher drops into the partially formed bag.

3.Sealing: The machine seals the top of the bag, simultaneously forming the bottom seal of the next bag, before cutting it free.

Best For

VFFS machines are the ideal solution for producers focused on speed, efficiency, and high-volume output. They excel in environments where large quantities of single-serve or standard-sized bags are the primary product. Businesses that benefit most from this technology include:

·Large-scale ready-to-eat popcorn manufacturers.

·Producers of other snack foods like chips, nuts, and candy.

·Companies packaging bulk goods such as coffee, spices, or grains.

Their versatility and speed make them a standard in the food industry for creating cost-effective, pillow-style bags ready for retail shelves.

Key Features

When selecting a VFFS machine, certain features are critical for optimizing popcorn packaging operations. These components enhance speed, preserve product quality, and minimize waste. Producers should look for systems equipped with the following technologies to maximize their return on investment.

1.Product Catcher: Popcorn is a very light, low-density product. A product catcher is an essential feature that improves cycle speed. It allows the popcorn to begin dropping while the machine's jaws are still sealing the previous bag. This simple mechanism significantly reduces the total drop time, leading to a higher output of bags per minute.

2.Nitrogen Dosing: Shelf life is a major concern for ready-to-eat snacks. Nitrogen dosing systems extend product freshness by displacing oxygen inside the bag before the final seal. This process, known as Modified Atmosphere Packaging (MAP), slows degradation. For popcorn, the goal is to achieve an oxygen level between 2-5%, protecting flavor and texture for longer.

3.Automatic Film Tracking (AFT): Consistent bag appearance is vital for brand perception. An AFT system ensures every bag is perfect. It automatically adjusts the film carriage to keep the packaging material centered. This prevents film drift, which can cause improper seals and unsightly packaging. AFT directly reduces film waste, minimizes machine downtime, and prevents yield loss.

Pro Tip Integrating these three features—a product catcher, nitrogen dosing, and automatic film tracking—transforms a standard VFFS machine into a highly efficient, quality-focused packaging solution specifically tailored for the unique challenges of popcorn production.

Premade Pouch Filling Machines for Gourmet & Branded Popcorn

What It Is

Premade Pouch Filling Machines automate the process of filling and sealing pouches that are already manufactured. Unlike VFFS systems that create bags from film, these machines work with pre-formed, often branded bags. This type of packing machine for popcorn is ideal for premium products that require high-quality packaging, such as stand-up pouches with resealable zippers. While effective, this approach has cost considerations. Premade bags generally incur higher material costs compared to rollstock films. The premade bag packing machine might also demand a greater initial investment than a VFFS machine.

How It Works

The operation is a precise, multi-station rotary or inline process. Each step ensures the pouch is handled carefully to maintain its premium appearance and structural integrity.

1.Pouch Feeding: The machine grips a single pouch from a magazine and transfers it to the filling line.

2.Opening & Filling: An air jet or mechanical grippers open the pouch. A multi-head weigher then dispenses the exact amount of popcorn into the open bag.

3.Sealing: The machine moves the filled pouch to a sealing station. Heated bars create a secure, clean seal across the top of the pouch.

4.Discharge: The finished, sealed pouch is discharged onto a conveyor for case packing.

Best For

These machines are the premier choice for brands prioritizing shelf appeal and consumer convenience. They are perfectly suited for gourmet popcorn producers who want their packaging to reflect the high quality of the product inside. Businesses that benefit most include:

·Artisanal or small-batch popcorn companies.

·Brands using stand-up, resealable pouches for multi-serving products.

·Producers seeking to differentiate their product on crowded retail shelves.

Did You Know?High-quality, resealable pouches can significantly enhance consumer perception of a brand. The convenient design and premium feel often justify a higher price point in the eyes of the shopper, making it a strategic choice for gourmet popcorn lines.

The ability to handle complex pouch designs with zippers, tear notches, and unique shapes makes this system invaluable for creating a standout product.

Key Features

Producers should evaluate specific features that enhance packaging quality, operational efficiency, and consumer experience. Premade pouch fillers offer advanced capabilities that justify their investment, particularly for brands aiming for a premium market position. Key technologies differentiate these systems and deliver significant value.

1.Pouch Versatility: These machines demonstrate remarkable flexibility. They can handle a wide range of pouch sizes, shapes, and materials. This adaptability allows a single machine to pack various products, from small single-serving bags to large, family-sized stand-up pouches. This versatility is crucial for brands that plan to expand their product lines.

2.Zipper and Slider Applicators: The ability to handle resealable closures is a primary advantage. These features add immense value by improving consumer convenience and extending product freshness.

·Zipper Closures: These press-to-close options offer an economical way to provide resealability. They create a strong barrier against moisture and oxygen, protecting the popcorn's flavor and texture.

·Slider Closures: Sliders provide a premium user experience with an effortless open-and-close track. They give consumers greater assurance of a complete seal, preventing air gaps. This ease of use is a significant benefit for all users, including children and older individuals.

1.No Pouch, No Fill Sensors: This smart feature is essential for minimizing waste and maximizing efficiency. The machine uses sensors to detect the presence of a pouch at the filling station. If a pouch is missing or improperly opened, the system will not dispense any popcorn. This prevents product spillage, reduces cleanup time, and lowers operational costs.

Maximizing Brand Impact Studies show that consumers are often willing to pay more for packaging with convenient features like resealability. Integrating a zipper or slider closure not only protects the product but also elevates the brand's perceived value on the shelf.

The Right Packing Machine For Popcorn in Rigid Containers

What It Is

Container filling lines are automated systems designed to fill and seal pre-formed rigid containers. This type of packing machine for popcorn handles packaging like plastic tubs, buckets, and jars. These machines are essential for products sold in bulk or as premium gift items. The containers themselves are typically made from durable plastics that protect the product and provide a large surface for branding.

| Packaging Type | Material |

|---|---|

| Plastic Popcorn Cylinder | PET or PP plastic |

| Popcorn Bucket with Lid | Polypropylene plastic |

These systems offer a robust solution for producers who prioritize product protection and a substantial shelf presence over flexible bags.

How It Works

The process begins with empty containers moving along a conveyor. A key component of many lines is the volumetric cup filler. This device offers an economical way to fill free-flowing products like popcorn. The filler operates through a simple, effective sequence.

1.Measuring cups rotate under a feed hopper and are filled with popcorn.

2.The plate continues to rotate, moving the filled cup over the container.

3.The popcorn drops from the cup into the container below.

After filling, the containers proceed to stations for sealing, capping, and labeling. To ensure consistent performance, these lines require regular maintenance. Operators perform daily cleaning of nozzles and conveyors and weekly disinfection to maintain food safety standards.

Best For

A container filling line is the best choice for brands targeting specific retail channels where packaging durability and presentation are critical. These systems excel for:

·Club Stores: Rigid containers are durable and stackable, making them ideal for the wholesale club environment. Their large "billboard area" allows for high-impact graphics that attract consumers.

·Gift Markets: The sturdy structure of tubs and jars conveys a sense of luxury. This makes them perfect for holiday tins, gift sets, and specialty food markets.

·Food Service: Large-format buckets are perfect for businesses selling popcorn in bulk to cinemas, stadiums, and other venues.

This packing machine for popcorn is a strategic investment for companies aiming to capture sales in high-volume or premium market segments.

Key Features

When evaluating a container filling line, producers should look beyond the filler to the entire integrated system. A complete line transforms individual packaging tasks into a cohesive, automated process. This synergy significantly enhances overall efficiency and ensures product uniformity. Key features work together to deliver a retail-ready product with minimal manual intervention.

1.Volumetric Cup or Multi-Head Weigher Integration: While volumetric cup fillers are a cost-effective option for many popcorn products, lines can also integrate with more precise multi-head weighers. This flexibility allows producers to choose the filling technology that best matches their product's characteristics and accuracy requirements.

2.Automated Capping Machines: After filling, an automated capper is essential for securing the product. These machines apply lids with consistent torque specifications. This process ensures every container is sealed properly, protecting the popcorn from moisture and contaminants while preventing spills during transit. It also accelerates production far beyond manual capabilities.

3.Inline Labeling Systems: A labeling machine applies brand and nutritional labels quickly and uniformly. Automating this step eliminates the inconsistent and time-consuming process of manual application. Precise, straight labels are vital for legal compliance and for creating a professional brand image on the shelf.

The Power of Integration

A fully integrated line offers a significant competitive advantage. Automation minimizes human contact, improving product safety and quality. The consistent, high-quality packaging enhances brand perception and customer trust, leading to a positive customer experience and repeat business.

Specialty Packers for Microwave Kits and Sachets

What It Is

Specialty packers are highly specialized automated systems designed to package products with multiple components, such as microwave popcorn kits. These machines, often configured as multi-lane sachet packers, create small, sealed packets for individual ingredients. They are engineered for precision, ensuring that each component—kernels, oil, and seasoning—is dosed accurately and packaged separately or together according to product specifications. This type of packing machine for popcorn is essential for creating the convenient, all-in-one kits consumers expect.

How It Works

The operation of a specialty packer is a sophisticated, synchronized process. Different machine modules handle specific ingredients. For liquid components like oil or butter, a dedicated system doses the precise volume into each sachet. For dry ingredients, the process is different. A machine designed for powder seasoning uses a storage tank to hold the product. A swinging cup mechanism then measures an exact portion before filling it into the sachet. The machine uses servo-controlled film pulling to advance the packaging material, followed by sealing to create clean, uniform packets at high speeds.

Single-Use Convenience The rise of on-the-go lifestyles has increased demand for single-serving products. Sachet machines meet this need by providing perfectly portioned, convenient packaging for a wide range of consumer goods.

Best For

These machines are the definitive solution for manufacturers of microwave popcorn kits. Their ability to handle multiple disparate ingredients makes them indispensable for this market segment. However, their utility extends far beyond popcorn. They are ideal for any brand that requires precise dosing for single-use products. Other common applications include packaging:

·Coffee and tea

·Spices and sugar

·Ketchup and sauces

·Creams and oils

·Mouth fresheners

This versatility makes them a valuable asset for companies producing a diverse portfolio of portion-controlled food and non-food items.

Key Features

Producers should assess several key technologies when selecting a specialty packer. These features ensure the precision, efficiency, and versatility needed to create high-quality, multi-component products like microwave popcorn kits. The right combination of capabilities directly impacts production speed and product consistency.

1.Multi-Component Dosing Systems: The primary strength of these machines is their ability to handle multiple ingredients simultaneously. They integrate different dosing systems into a single frame. One system, like a cup or auger filler, measures dry kernels and seasonings. Another system handles the liquid oil or butter component. This integrated approach ensures each sachet contains the correct ratio of all ingredients.

2.Advanced Liquid Filling Technology: Packaging oily or viscous liquids requires specialized features to maintain accuracy and hygiene. The liquid filling module must offer robust capabilities.

·Precision dosing to prevent spillage and ensure consistent volume in every packet.

·The ability to handle varying liquid viscosities, from thin oils to thicker butter flavorings.

·Secure sealing to create a leak-proof packet that protects other components.

·Hygienic design with easy-to-clean parts to maintain food safety standards.

1.Servo-Driven Control: Modern specialty packers use servo motors for critical functions like film pulling and sealing. Servo technology provides exceptional precision and control over machine movements. This results in consistent packet lengths, perfectly aligned seals, and high-speed operation. It also reduces mechanical wear and minimizes machine downtime, boosting overall production efficiency.

Technical Insight The choice of dosing mechanism is critical. An auger filler provides excellent accuracy for fine powders like seasonings. A piston pump, on the other hand, is ideal for precisely dosing viscous liquids like butter. Matching the filler to the ingredient is fundamental for successful kit packaging.

Selecting the right packing machine for popcorn requires a clear strategy. Each machine type serves a distinct purpose for producers.

·VFFS machines are the standard for high-speed, single-serve bags.

·Premade Pouch Fillers are ideal for premium brands. They handle resealable pouches that consumers prefer for maintaining freshness.

·Container Filling Lines offer the best solution for gift-ready tubs and jars.

·Specialty Sachet Packers provide the precision needed for microwave popcorn kits.

Aligning the machine choice with specific production goals and scalability needs is the key to a smart investment.

FAQ

What is the best entry-level machine for a startup?

VFFS machines are often the most cost-effective choice for new businesses. They provide high-speed bagging capabilities at a lower initial investment compared to other automated systems. This makes them an accessible option for producers scaling up their operations.

How does nitrogen flushing preserve popcorn freshness?

Nitrogen flushing displaces oxygen inside the package before sealing. This process, known as Modified Atmosphere Packaging (MAP), slows down product degradation. It effectively protects the popcorn's flavor and texture, significantly extending its shelf life on retail shelves.

Can one machine pack different bag sizes?

Yes, versatility is a key feature of many modern packers. Premade pouch fillers, in particular, excel at handling a wide range of pouch sizes and styles. This allows a single machine to support a diverse and expanding product line.

Why choose rigid containers instead of flexible bags?

Producers choose rigid containers for superior product protection and shelf presence. Tubs and jars are durable, stackable, and offer a large surface for branding. They are ideal for club stores, gift markets, and food service applications.

Post time: Dec-19-2025