The form-fill-seal machine market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.49% from 2024 to 2035, underscoring the rising demand for efficient automation. Selecting the correct equipment is a critical business decision. A vffs packing machine uses gravity to package loose, free-flowing goods like snacks and powders. In contrast, HFFS machines utilize a conveyor-based method for solid or delicate items like candy bars and medical devices.

Key Takeaway: The product's physical characteristics—whether it is loose or solid—fundamentally determine the ideal packaging solution.

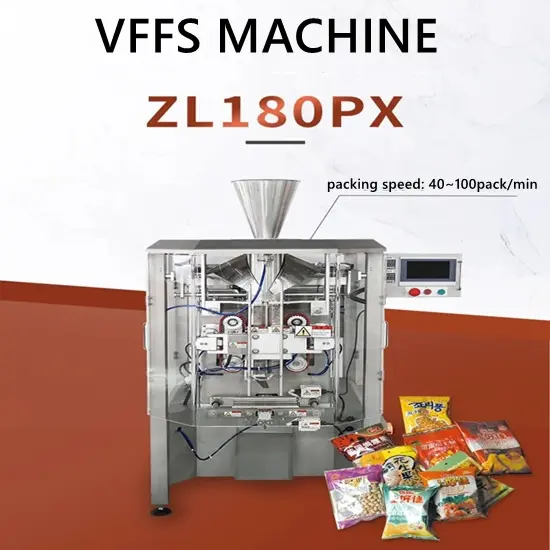

Understanding the VFFS Packing Machine Workflow

A Vertical Form Fill Seal (VFFS) machine operates on a simple yet highly effective principle. It forms bags from a flat roll of film, fills them with product from above, and then seals them shut in a continuous vertical motion. This streamlined process makes it an exceptionally efficient solution for high-volume production lines.

The Gravity-Fed Advantage

The core strength of a vffs packing machine lies in its use of gravity. Product is dispensed from a weigher or filler positioned directly above the packaging tube. Gravity pulls the product down into the pre-formed bag, ensuring a fast and consistent fill. This method is ideal for items that flow easily and are not susceptible to damage from a drop. The vertical orientation also minimizes the machine's footprint, saving valuable floor space in a production facility.

Note: The gravity-fed system is the key to the high speeds associated with VFFS technology, making it a powerhouse for bulk packaging operations.

Common Products for VFFS

The gravity-assisted workflow makes the vffs packing machine perfect for a wide array of loose or granular products. Its applications span numerous industries, from food and beverage to hardware. Common product categories include:

·Granular and Powdered Items: Sugar, rice, coffee beans, flour, protein powders, and spices.

·Snack and Frozen Foods: Potato chips, nuts, granola, frozen vegetables, and dried fruit.

·Emerging Categories: Superfood blends, alternative meat crumbles, and other premium specialty foods.

Technology continues to push the boundaries of what a vffs packing machine can handle. For instance, the innovative Tight-Chicken™ system now allows for the airtight packaging of whole chickens. This "second skin" packaging, created on a single VFFS unit, demonstrates the expanding versatility of this vertical technology.

How HFFS Machines Handle Solid and Delicate Products

Horizontal Form Fill Seal (HFFS) machines offer a different approach to packaging automation. They are engineered specifically for products that cannot be dropped or handled by a gravity-fed system. An HFFS machine transports items horizontally, providing the gentle handling required for solid, delicate, or irregularly shaped goods. This method ensures product integrity from the start of the packaging process to the final seal.

The Conveyor-Based Method

The defining feature of an HFFS machine is its conveyor-based system. Operators or automated systems place products directly onto an infeed conveyor. The conveyor then moves each item horizontally into the packaging station. Film unwinds from a roll and forms a continuous tube around the product. The machine then seals and cuts the film to create individual packages. This horizontal orientation is ideal for maintaining product arrangement and preventing damage.

Key Difference: The primary distinction between the two systems is product movement. HFFS machines use a conveyor for gentle transport, while VFFS machines rely on gravity for speed.

The table below outlines the key mechanical differences between the two systems:

| Feature | HFFS System | VFFS System |

|---|---|---|

| Product Movement | Utilizes a horizontal conveyor belt | Relies on gravity to drop product from above |

| Pouch Formation | Unwinds film, seals bottom, then sides | Pulls film through a tube, seals bottom |

| Filling Method | Fills through the top opening of the pouch | Fills the bag from above |

| Sealing Process | Seals with closures (zippers, nozzles, caps) | Seals the top of the current bag (bottom of next) |

| Orientation | Horizontal | Vertical |

Common Products for HFFS

The gentle, conveyor-driven process makes HFFS machines the premier choice for a wide range of items that require careful handling or specific orientation. This technology is essential in the food, pharmaceutical, and medical industries. Common applications include:

·Solid and Single-Item Foods: Candy bars, granola bars, baked goods, and individually wrapped items.

·Medical and Pharmaceutical Products: HFFS technology produces flowpacks for sterile and sensitive items.

·Medical devices like syringes, IV bags, inhalers, and diagnostic tests.

·Solid pharmaceuticals such as blister packs, sterile gauze, and strip tablets.

·Multi-Packs and Kits: Grouping multiple items, like hardware kits or secondary packaging for single-dose products.

VFFS vs. HFFS: A Head-to-Head Comparison

Choosing between a VFFS and HFFS system requires a detailed analysis of your production needs. While both automate the form-fill-seal process, their core designs lead to significant differences in speed, space requirements, and packaging capabilities. Examining these factors head-to-head will clarify which machine aligns best with your operational goals.

Production Speed and Volume

Production speed is often a primary driver in equipment selection. In this category, VFFS machines hold a distinct advantage for high-volume operations. The gravity-fed design allows for a continuous, rapid workflow. Standard Vertical Form Fill Seal (VFFS) machines typically operate at production speeds ranging from 20 bags per minute up to more than 200 bags per minute. This high throughput makes them the industry standard for bulk goods like chips, coffee, and grains.

HFFS machines, by contrast, operate at a more deliberate pace. The horizontal conveyor system involves more mechanical steps, including placing items, moving them into the forming tube, and sealing them without disruption. This process prioritizes gentle handling over raw speed, making it ideal for delicate or precisely arranged products.

Operational Tip: If your primary goal is maximizing the number of packages produced per hour with a flowable product, a VFFS system is the clear frontrunner. If product integrity and careful placement are more critical than speed, HFFS is the superior choice.

Factory Footprint and Layout

The physical space a machine occupies is a critical logistical consideration. The names themselves—vertical versus horizontal—hint at their fundamental difference in layout. A vffs packing machine utilizes vertical space, resulting in a significantly smaller factory floor footprint. This design is ideal for facilities where floor space is at a premium.

HFFS machines require a much longer, linear footprint to accommodate the infeed conveyor, forming station, and sealing area. This horizontal layout demands more floor space but can be advantageous for integrating manual loading stations or complex inspection systems along the line.

The table below summarizes the typical spatial demands:

| Factor | VFFS Machine | HFFS Machine |

|---|---|---|

| Floor Footprint | Compact and square | Long and rectangular |

| Space Requirement | Needs vertical height clearance (e.g., 4m) | Needs horizontal floor length |

| Typical Dimensions | Approx. 2.5m x 1.8m floor space | Length can easily exceed 5m-6m |

| Layout Benefit | Fits easily into tight production cells | Allows for easy access along the line |

Packaging Styles and Features

Both VFFS and HFFS machines produce high-quality, professional packaging, but they excel in different areas. VFFS systems are masters of creating simple, efficient bag styles at high speed. Common formats include:

·Pillow Bags: The most common and cost-effective bag type.

·Gusseted Bags: Provides a more structured, "boxy" shape for better shelf presence.

·Block-Bottom Bags: A flat-bottomed bag that can stand upright on its own.

HFFS machines offer greater versatility for more complex and premium packaging formats. Because the product is carried on a conveyor, the system can create sophisticated pouches that require specific handling, such as stand-up pouches (SUPs) and pouches with spouts or unique shapes.

Furthermore, both systems can incorporate value-added features to enhance consumer convenience. Resealable closures are a popular option for multi-use products. These features help preserve freshness and improve the user experience. Common resealable options include:

·Resealable zippers: Allow consumers to easily open and close the package.

·Powder-proof zippers: Use a special design to prevent fine particles from clogging the seal.

·Child-resistant closures: Provide an essential safety feature for regulated products.

·Dual-track or flange zippers: Offer a more robust and secure seal for a premium feel.

While these features can be added to many bag styles, they are frequently associated with the stand-up pouches and flow-wraps commonly produced on HFFS lines.

Initial Investment and Operating Costs

A financial analysis is a cornerstone of any major equipment purchase. The decision between a VFFS and HFFS machine involves evaluating both the upfront capital expenditure and the long-term operational expenses. These costs can vary significantly based on the machine's complexity, features, and intended application.

A company's initial outlay for packaging equipment is a primary consideration. Generally, entry-level VFFS machines may be more affordable at the outset compared to flow pack machines (HFFS). The simpler mechanical design of a VFFS system, which relies on gravity, often results in a lower manufacturing cost and, consequently, a more accessible price point for businesses entering automated packaging.

For businesses looking at basic, high-speed bagging, an entry-level VFFS machine presents a compelling financial case. The typical cost for such models can be quite competitive.

| Feature | Entry-Level VFFS |

|---|---|

| Price Range | $3,000 - $10,000 |

In contrast, HFFS machines typically command a higher initial investment. Their sophisticated conveyor systems, precision engineering for gentle product handling, and capacity for complex package formats contribute to a higher price. This upfront cost reflects the machine's advanced capabilities and versatility.

Beyond the initial purchase, operating costs determine the machine's total cost of ownership and long-term profitability. Key factors include:

- Maintenance and Spare Parts: VFFS machines often have fewer moving parts directly involved in product transport, which can lead to more straightforward maintenance routines. HFFS machines, with their extensive conveyor belts and product carriers, may require more intensive upkeep to ensure smooth operation.

- Film and Material Usage: Both systems are designed for efficiency, but the type of packaging impacts material costs. VFFS machines excel at producing simple pillow bags with minimal film waste. HFFS machines creating complex stand-up pouches or using thicker laminates might consume more material per package.

- Labor Requirements: A highly automated VFFS line for free-flowing products can run with minimal operator oversight. An HFFS line, especially one packaging kits or delicate items, may require manual labor to load products onto the infeed conveyor, influencing ongoing labor costs.

- Changeover Time: The time it takes to switch between different products or package sizes is a critical operational cost. Modern machines on both platforms offer features to speed up this process, but the complexity of an HFFS system can sometimes lead to longer changeover procedures compared to a more straightforward VFFS setup.

Financial Insight : The best investment is not always the machine with the lowest price tag. A comprehensive cost analysis should project the Total Cost of Ownership (TCO) over several years. The right machine provides the best return on investment by aligning its capabilities and operational efficiency with your specific product and production goals.

Advanced Features and System Integration

Modern packaging machines are more than just mechanical systems; they are sophisticated platforms that integrate advanced technology to boost efficiency, precision, and usability. Understanding these features is key to unlocking a machine's full potential and maximizing your return on investment.

Servo Control Systems for Precision

Precision is paramount in packaging. Advanced machines utilize a 3-servo control system to achieve exceptional stability, accuracy, and speed with lower noise levels. Servo-driven systems offer precise control over every part of the packaging process, from film pulling to sealing. This level of accuracy ensures each bag is filled to the exact weight specification and sealed perfectly. The result is a significant reduction in both product giveaway and material waste. By minimizing excess film usage and decreasing bag overhang, servo technology lowers overall packaging costs while consistently producing high-quality, uniform packages.

Integrating Weighers and Fillers

A packaging machine operates as part of a larger production line. Seamless integration with upstream equipment is therefore essential for a smooth workflow.

·VFFS Integration: A VFFS machine can easily connect with various filling systems. Common integrations include multi-head weighers for snacks, electrical weighers for precise measurements, and volume cup fillers for granular products like sugar or rice.·

·HFFS Integration: HFFS lines can incorporate advanced automation like robotic arms. These compact robot cells use vision systems to detect, pick, and place products onto the infeed conveyor, a process ideal for delicate or irregularly shaped items that require specific orientation.

Pro Tip : Integrating the right filler or weigher directly impacts your line's speed and accuracy. The choice depends entirely on your product's characteristics.

Touch Screen Operation for Ease of Use

Modern packaging lines have moved beyond complex buttons and dials. Today's machines feature intelligent, user-friendly touch screen interfaces, also known as Human-Machine Interfaces (HMIs). These HMIs make operation simpler and more intuitive. Operators can use the graphical display to:

·Visually monitor production data and key performance indicators (KPIs).

·Adjust machine settings like speed and temperature with a few taps.

·Manage different packaging types, such as pillow bags or connected bags.

·Receive real-time feedback and alarms to address issues quickly.

This digital control center centralizes operational management, reduces the chance of human error, and simplifies the process of training new staff.

A 3-Step Checklist to Finalize Your Decision

Selecting the right machine requires a structured approach. This three-step checklist helps businesses systematically evaluate their needs to make an informed and confident investment.

Step 1: Analyze Your Product's Characteristics

A deep analysis of the product itself is the foundational step. For powders and granular goods, a key metric is the 'angle of repose,' which measures flowability. This angle determines if a product is free-flowing or non-free-flowing, a critical factor for VFFS machines with auger fillers. The machine's agitator settings are adjusted based on this property to ensure consistent product flow and prevent blockages.

| Flow | Repose Angle (°) |

|---|---|

| Excellent | 25-30 |

| Good | 31-35 |

| Fair | 36-40 |

| Passable | 41-45 |

| Poor | 46-55 |

For solid or delicate items, companies must consider if the product can withstand a drop or if it requires gentle horizontal handling to maintain its integrity.

Step 2: Define Your Operational Requirements

Next, businesses must evaluate their production environment. For food and pharmaceutical applications, sanitation is a top priority. Machines must be designed for effective Clean-in-Place (CIP) procedures to ensure safety and prevent cross-contamination. This requires hygienic design principles, such as using non-porous, corrosion-resistant materials like food-grade stainless steel. Additionally, designs should feature sloped surfaces of at least 3 degrees to prevent residue from pooling and ensure all components are wash-down ready for thorough cleaning.

Step 3: Determine Your Final Packaging Goals

Finally, a company must define its ultimate packaging objectives. Consumer preferences are shifting heavily toward sustainability. A recent survey shows 68% of companies have made public commitments to sustainable packaging. This trend influences material choices, favoring recyclable or compostable options. Modern packaging also incorporates smart technology like QR codes, which allow consumers to access information on material sources and recycling instructions. The final package must not only protect the product but also align with brand values and meet evolving market expectations for eco-friendliness.

Selecting the correct packaging system requires aligning a product's nature with the machine's core strengths. A vffs packing machine provides the ideal solution for high-speed, efficient packaging of loose and flowable goods. In contrast, HFFS machines offer the versatility and gentle handling necessary for solid, multi-component, or delicate items.

A confident decision matches the machine to specific production, space, and packaging needs. This alignment ensures long-term growth and operational success.

FAQ

Can one machine perform both VFFS and HFFS functions?

No, these machines have fundamentally different designs. A VFFS machine uses a vertical, gravity-fed system. An HFFS machine uses a horizontal conveyor. A business must select the machine that matches its specific product characteristics and packaging requirements.

How difficult is it to change package sizes on these machines?

Modern machines feature intelligent designs for easier changeovers. Operators can manage settings through a touch screen interface. VFFS systems require changing the forming tube and film roll. HFFS systems involve adjusting the conveyor guides and sealing mechanisms for the new product dimensions.

Can a VFFS machine handle liquids and sauces?

Yes, specialized VFFS machines can package liquids. These models integrate with liquid pump fillers and use specific film materials to create a secure seal. This capability makes them suitable for products like sauces, soups, and dressings, expanding their use beyond dry goods.

What are the primary maintenance considerations?

Maintenance needs differ based on machine complexity. VFFS machine upkeep often centers on the film transport and sealing jaws. HFFS machines require additional maintenance for the extensive conveyor system, which contains more moving parts and requires regular inspection and cleaning.

Expert Tip : A preventative maintenance schedule is crucial for both systems. It ensures long-term reliability, minimizes downtime, and protects the initial investment.

Post time: Nov-25-2025