1. Implement a Proactive Maintenance Schedule

Moving from reactive repairs to a proactive schedule is the smartest change you can make. A planned approach helps you catch small issues before they become major breakdowns. You should create a detailed schedule based on your machine's usage and the manufacturer's advice.

A successful maintenance plan includes several key practices:

1.Perform routine inspections with trained personnel.

2.Establish a lubrication schedule for all moving parts.

3.Implement regular cleaning routines to prevent debris buildup.

4.Test and calibrate the machinery to ensure optimal performance.

5.Prioritize safety by regularly checking guards and emergency stops.

Daily Pre-Operation Checks

Your day should always begin with a quick but thorough inspection. These checks confirm the machine is safe and ready for production. Before starting a shift, your operator should quickly examine key areas like the main assembly, feeder, sealer, cutter, and conveyor. They need to look for any visible damage, remove debris, and check for loose parts.

Safety First!

Always verify that all safety features, including guards, interlocks, and emergency stop buttons, are in place and working correctly before any operation.

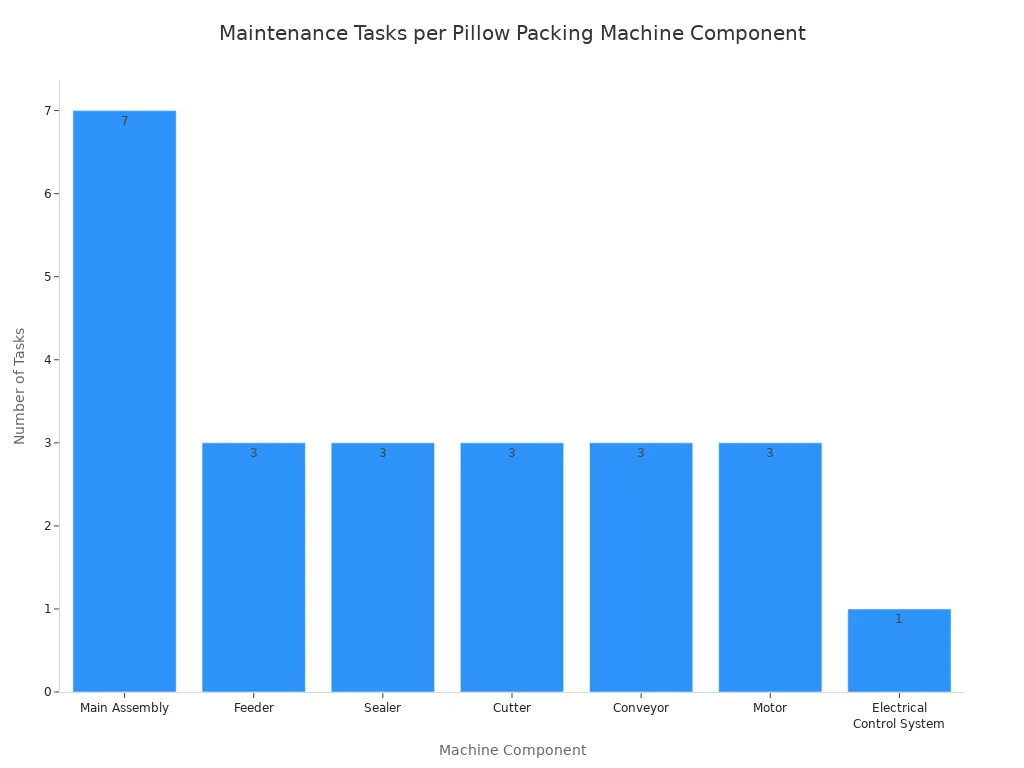

The number of daily checks varies by component, with the main assembly requiring the most attention.

Weekly Inspections

Weekly tasks involve a slightly deeper look at your machine's components. These inspections help maintain the quality of your packaging. For example, you should clean the conductive rings of the mid-sealing tool and end sealers. After turning off the main power, you can gently clean these parts with sandpaper to remove residue. This simple action prevents poor seals and ensures consistent product quality.

Monthly and Quarterly Tasks

Monthly and quarterly maintenance focuses on longevity and precision. Each month, you should lubricate essential components like bearings and gears with manufacturer-recommended oils. You also need to tighten all fasteners, screws, and electrical connections that may have loosened from vibration.

Every quarter, you must perform critical calibrations. A common blind spot is the transmission belt tension, which directly affects packaging accuracy. This is also the ideal time to replace common wear parts like gaskets, seals, and belts to maintain peak performance.

2. Master Routine Cleaning and Lubrication

A clean and well-lubricated machine is a reliable machine. Debris and friction are two of the biggest enemies of consistent performance. You can prevent many common failures by mastering these fundamental maintenance tasks.

Daily Cleaning Procedures

You should make cleaning a standard part of your end-of-shift routine. This simple habit keeps parts in good condition and extends their lifespan. Always start by turning off the machine and disconnecting the power to ensure safety.

Follow these steps for an effective daily clean:

1.Remove Debris: Use a soft brush or vacuum to clear away product crumbs, dust, and film fragments. Pay close attention to the metering parts and conveyor belts.

2.Wipe Surfaces: Use a soft cloth and a suitable cleaning agent to wipe down the machine. This helps maintain clear sealing lines on your packages.

3.Clean Electricals: Gently clean any dust from the electric control box. This simple action helps prevent short circuits and poor electrical contacts.

4.Dry Completely: Dry all surfaces with a clean cloth or an air gun to stop rust from forming.

Strategic Lubrication Points

Proper lubrication keeps your machine's moving parts operating smoothly. Different components require specific lubricants, so you must consult your machine's manual. For food packaging, always use food-grade greases like Super Lube to prevent contamination.

Lubrication Best Practices Create a lubrication chart that maps every grease point and its recommended schedule. This helps you apply the right amount of lubricant at the right time. Remember, too much grease can attract dust and damage seals.

Cleaning the Film Pathway

A clean film pathway is essential for creating perfect packages. Any obstruction or residue can cause significant quality issues. If you notice problems with your packaging, a dirty film path is often the culprit.

An unclean pathway can lead to:

·Wrinkles in the film before it meets the package.

·Film jams or poor feeding from sticky rollers.

·Uneven package seals or open areas on the bottom.

·Twisted packages during the folding or sealing process.

Regularly inspect and clean the film rollers, clamps, and feed table to ensure the film travels smoothly from the roll to the final sealed package.

3. Inspect and Adjust Key Components of Your Pillow Packing Machine

Your machine's mechanical parts work hard every shift. Regular inspections of these components prevent poor package quality and unexpected breakdowns. You can keep your pillow packing machine in top condition by focusing on three critical areas: the sealing and cutting tools, the film feed, and the conveyors.

Sealing Jaws and Cutting Knives

The sealing jaws and cutting knives create the final package. Their condition directly impacts product safety and appearance. You should inspect them regularly for signs of wear or damage. Misaligned or worn parts lead to costly product waste and packaging failures.

Look for these common warning signs:

·Inconsistent or weak seals that compromise package integrity.

·Blunt or damaged cutting blades that result in poor cuts.

·Adhesive residue or film debris building up on the jaw surfaces.

·Uneven gear wear that causes the jaws to mesh too tightly.

Addressing these issues promptly ensures every package is sealed securely and cut cleanly.

Film Feeding System

The film feeding system guides the packaging material through the machine. A smooth, uninterrupted path is essential for forming perfect bags. You need to check the film rollers, tensioners, and guides for proper alignment and movement. Any friction or misalignment can cause the film to wrinkle, tear, or jam. Ensure all rollers spin freely and are free of any sticky residue. A well-adjusted film feed is a key part of a reliable pillow packing machine.

Conveyor Belts and Chains

Conveyor belts and chains move your products smoothly into and away from the machine. Incorrect tension is a primary cause of conveyor problems. You might notice squealing noises, frayed belt edges, or frequent stalling if the tension is off. Check that the belt edges are flush and parallel.

Pro Tip: Check for Debris! Always look for product crumbs or other debris under the belt. Buildup can cause the belt to stretch and lose tension, leading to malfunctions and misalignment.

Regularly inspect the belts and chains for wear and adjust the tension according to your manufacturer’s guidelines. This simple check keeps your entire production line flowing without interruption.

4. Monitor Electrical and Pneumatic Systems

Your machine's electrical and pneumatic systems are its nervous system and muscles. You must monitor them closely to prevent sudden failures. These systems control everything from sealing pressure to bag length, so their health is critical for consistent production.

Electrical Cabinet and Wiring Checks

A safe and clean electrical cabinet prevents unexpected shutdowns. You should make electrical inspections a routine part of your maintenance. Always disconnect the power before opening the cabinet.

Follow these safety steps during your inspection:

·Inspect all wiring for signs of wear, fraying, or damage.

·Check that every electrical connection is tight and secure.

·Ensure the machine is properly grounded to prevent electrical hazards.

·Keep the cabinet free of dust and debris to avoid short circuits.

Pneumatic System Integrity

The pneumatic system uses compressed air to power key movements, like sealing and cutting. Air leaks waste energy and cause inconsistent performance. You can easily test for leaks to keep the system efficient.

How to Find Air Leaks Pressurize your system and listen for hissing sounds. You can also apply a soapy water solution to fittings and connections. Bubbles will form at the site of any leak. If the system pressure holds steady for 10 minutes, it is likely secure. Tighten or replace any faulty fittings to fix the issue.

Sensor and Photocell Calibration

Sensors and photocells ensure your machine cuts bags to the correct length and aligns printed film perfectly. You need to calibrate them regularly for accurate packaging. An uncalibrated sensor can lead to wasted film and poorly presented products.

To calibrate the photocell for print registration, you must train it to recognize the eye mark on your film. First, you position the mark under the sensor and teach the sensor to see it. Next, you measure the distance between eye marks and enter this value into the machine’s control screen. This simple adjustment ensures every bag is cut precisely where it should be.

5. Standardize Operator Training and Procedures

Your operators are the first line of defense in maintaining machine health. Properly trained operators are fundamental for a packaging line that runs smoothly and efficiently. You can empower your team by standardizing their training and daily procedures. This approach ensures everyone knows how to operate the machine correctly and spot problems early.

Foundational Operator Responsibilities

You should empower your operators to take ownership of their machines. This concept, known as autonomous maintenance, involves them performing routine care tasks. Their daily responsibilities are simple but crucial for preventing breakdowns.

Operators should focus on these core duties:

- Keep it clean: Remove product debris and dust from all surfaces.

- Keep it lubricated: Follow the lubrication schedule to reduce friction.

- Monitor for issues: Listen for unusual noises and watch for vibrations.

- Tighten and secure: Check for and tighten any loose bolts or fasteners.

Training on Fault Recognition

Your training program must teach operators how to recognize common faults. When they can spot warning signs, they can alert maintenance before a small issue becomes a major failure. You can create a simple troubleshooting guide for your team.

| Common Problem | What to Check First |

|---|---|

| Machine won't start | Is the main power on? Is a safety guard open? |

| Poor package seals | Is the sealing temperature correct? Are the jaws clean? |

| Film tracking improperly | Is the film path clear of debris? Are rollers sticky? |

This knowledge helps operators quickly identify the root cause of many production stops, from a printer being offline to low air pressure.

Creating Standard Operating Procedures (SOPs)

You need to document all best practices in Standard Operating Procedures (SOPs). These written guides ensure every operator performs tasks the same way, from basic operation to advanced troubleshooting. Your training should combine learning with practical experience.

A Path to Mastery An effective training plan starts with the basics, like using the control panel. It then moves to advanced topics like safety protocols and maintenance. Finally, you must provide hands-on experience where operators run the machine under expert supervision.

6. Manage a Strategic Spare Parts Inventory

Downtime is expensive, but waiting for a replacement part to arrive is even worse. You can avoid long delays by managing a strategic spare parts inventory. This ensures you have the right components on hand when you need them most. A well-organized stock of parts keeps your production line running smoothly.

Identifying Critical Wear Parts

You do not need to stock every part for your machine. Instead, you should focus on the most critical components. You can classify parts based on their importance to production. This method is sometimes called VED analysis.

- Vital (V): Your production stops completely without these parts.

- Essential (E): The machine can run, but at a lower capacity or quality.

- Desirable (D): The absence of these parts causes minor issues.

Focus your inventory on the Vital and Essential parts to prevent major shutdowns.

Organizing Your Spare Parts Stock

A disorganized stockroom costs you valuable time. You should create a system that makes finding parts fast and easy. A logical layout improves your maintenance workflow.

1.Use QR Labels: Place a QR code on each part or bin. You can scan the code to see the part number, location, and reorder status instantly.

2.Organize Shelving: Arrange your shelves based on part size and weight. Use heavy-duty shelves for large items and small bins for screws or sensors.

3.Optimize Your Layout: Store frequently used parts in easily accessible locations. This simple step shortens retrieval times and gets your machine back online faster.

Establishing Reorder Points

A reorder point is the minimum stock level that triggers a new order. Setting this point correctly prevents you from running out of a critical part. It acts as an automatic reminder to restock before your inventory is empty.

The Reorder Point Formula Your reorder point is your lead time demand plus your safety stock. Lead time demand is the number of parts you use while waiting for a new order to arrive. Safety stock is the extra inventory you keep for unexpected delays.

Calculating this number ensures you always have enough parts to cover lead times and unexpected demand. This simple formula is your best tool for preventing stockouts.

7. Keep Detailed Maintenance Logs

Good records are your most powerful maintenance tool. Keeping detailed logs helps you track your machine's history and make smarter decisions. This practice prevents unexpected breakdowns and extends your equipment's lifespan. A clear audit trail also improves workplace safety and accountability.

What to Record in Your Logbook

Your logbook should tell a complete story of every maintenance action. You need to capture enough detail to make the information useful later. A thorough entry ensures anyone can understand what was done and why.

Logbook Essentials Every entry should include these key details:

·Equipment ID: The machine name, model, and serial number.

·Date and Time: When the service or inspection occurred.

·Technician: The name of the person who performed the work.

·Work Description: A clear summary of the tasks performed.

·Parts Replaced: A list of any new components installed.

·Findings: Notes on the machine's condition or performance.

Using Data to Predict Failures

Your maintenance logs are more than just a history book. You can use this data to predict future problems. By analyzing your records, you can spot trends that signal an impending failure. For example, you might notice a specific part needs replacement after a certain number of operating hours. This allows you to schedule maintenance before the part breaks. This data-driven approach helps you move from reactive repairs to predictive maintenance, saving you time and money.

Choosing Between Digital and Physical Logs

You can keep your records in a physical notebook or a digital system. Each method has its own advantages. You should choose the one that best fits your team's workflow

| Feature | Physical Logbook | Digital Logbook |

|---|---|---|

| Accessibility | Simple and requires no technology. | Accessible from anywhere with an internet connection. |

| Data Analysis | Difficult to analyze trends over time. | Easy to search, filter, and create reports. |

| Durability | Vulnerable to damage, loss, or spills. | Securely backed up to prevent data loss. |

| Ease of Use | Familiar and has no learning curve. | May require some training to use effectively. |

A digital log is often better for analyzing data, while a physical book is simple and always available on the shop floor.

You should view smart maintenance as a crucial investment in your production line's reliability. Consistent upkeep is the key to preventing major failures. It directly extends the lifespan of your pillow packing machine. You empower your team with these practices to achieve and maintain peak performance.

This commitment protects your pillow packing machine from unexpected downtime. A well-maintained pillow packing machine ensures your operations run smoothly and efficiently every single day.

FAQ

How often should I perform maintenance?

You should perform quick checks daily before starting your shift. Deeper inspections and lubrication tasks are necessary on a weekly and monthly basis. Always consult your machine’s manual for a detailed schedule based on your specific model and production volume.

What is the most important daily maintenance task?

Cleaning is your most critical daily task. You must remove all product crumbs, dust, and film fragments at the end of every shift. This simple habit prevents debris buildup, which is a primary cause of jams and poor package quality.

Why are my package seals weak or inconsistent?

Weak seals often result from incorrect sealing temperatures or dirty sealing jaws. First, you should verify that the temperature setting is correct for your film. Next, inspect the jaws for any residue or wear and clean them thoroughly.

Do I need to stock every spare part for my machine?

No, you do not need to stock every component. You should focus your inventory on critical wear parts. These are the essential items, like belts and blades, that would completely stop your production line if they failed. This strategy prevents long downtimes.

Post time: Nov-14-2025