A high-speed pillow packing machine forms a continuous tube from a film roll. It inserts products at set intervals, then seals and cuts the tube into individual 'pillow' pouches. The entire process relies on four synchronized mechanical stages: film forming, product feeding, sealing, and cutting. These machines are a key part of the growing global packaging industry.

Global Packaging Machinery Market Outlook

Metric Value (2025) Value (2034) Growth Rate (CAGR) Market Size USD 53.26 billion USD 83.34 billion 5.1%

A modern pillow packing machine can operate at speeds ranging from 30 to as high as 1200 packs per minute.

Stage 1: Film Unwinding and Forming

The entire packaging process begins with a large roll of flat packaging film. This film is mounted on a spindle. A system of rollers, called the film transport system, pulls the film from the roll. These rollers guide the film and maintain proper tension. Correct tension is crucial for a smooth operation.

From Film Roll to Tube

The machine unwinds the film at a constant speed. It travels from the spindle toward the next stage. These machines handle many types of packaging films. Common materials include:

- BOPP Film (Biaxially Oriented Polypropylene)

- BOPET Film (Biaxially Oriented Polyethylene Terephthalate)

- CPP Film (Cast Polypropylene)

- PE Film (Polyethylene)

- Aluminum Foil

- Shrink Film

BOPP film is a very popular choice for flexible packaging. Manufacturers often use it as an overwrap film. The food industry uses it to seal items like baked goods, snack foods, and confections.

The film remains flat as it moves through the initial set of rollers. Its journey then takes it directly to the forming box. This is where the film’s transformation begins.

The Role of the Forming Box

The forming box, also known as a "former" or "forming shoulder," is a specially shaped metal piece. It is the key component for shaping the package. The flat film wraps around the outside of this former. The former’s unique design folds the film over on itself. This action creates a continuous tube from the flat sheet. The two outer edges of the film now overlap, preparing them for the first seal. The product will later be inserted into this newly formed tube. The size and shape of the forming box determine the final width and height of the finished pillow pack.

Stage 2: Product Infeed and Synchronization

While the former shapes the film into a tube, the machine simultaneously prepares to introduce the product. This stage is critical. The machine must perfectly synchronize the product's entry with the moving film tube. This ensures each item is placed correctly before the final sealing and cutting.

The Infeed Conveyor System

The infeed conveyor system transports products to the packaging area. It consists of a moving belt or chain that carries items forward. Operators or automated systems place products onto this conveyor. The conveyor then moves them in a single file line toward the film tube. Different products require different types of conveyors for optimal handling. Common systems include:

- Flight bar infeed conveyors, which use bars or "flights" to separate items.

- Dual belt pacing infeeds that use belts to position products.

- Incline conveyors for moving items to a different height.

- Belt conveyors, often used for reclaimed product takeaway.

The conveyor's speed is precisely matched to the speed of the film transport system. This coordination is the first step in achieving perfect synchronization.

Ensuring Precise Product Spacing

Proper spacing between products is essential for a successful packaging run. Modern machines often use advanced servo-driven systems to control this process. Servo systems offer incredible speed and accuracy. They allow for quick adjustments and make shorter production runs more economical.

The benefits of servo-driven systems are significant:

- High Speed and Accuracy: They operate with precision even at top speeds.

- Flexibility: Their programmable nature simplifies running new products.

- Fast Changeovers: Operators can load pre-stored product recipes from a touchscreen. This reduces downtime and minimizes manual adjustments.

- Enhanced Diagnostics: These systems monitor machine health and help identify the cause of jams or other faults.

Without this precision, major problems can occur down the line.

At high speeds, even a small misalignment can disrupt downstream processes like labeling, coding, or cartoning. The best designs minimize complexity while ensuring smooth product flow and reducing jams.

Ultimately, the goal is to drop each product perfectly into the center of what will become a sealed pillow pack.

Stage 3: The Sealing Process in a Pillow Packing Machine

After the product is correctly positioned inside the film tube, the sealing process begins. This stage is where the package takes its final, secure form. The machine performs two distinct sealing actions: a longitudinal seal that runs the length of the pack and two transverse seals that close the ends.

Creating the Longitudinal Fin Seal

The longitudinal seal, often called a "fin seal," is the seam that runs along the bottom or top of the pillow pack. It is created by joining the two overlapping edges of the film that were brought together by the forming box.

A series of heated, driven wheels, known as fin seal wheels, create this continuous seal. These wheels apply both pressure and heat to the film. The process typically involves multiple pairs of wheels working in sequence:

1.The first pair of wheels, which are often unheated, grip the film and pull the tube forward through the pillow packing machine.

2.The second and third pairs are heated. They press the overlapping film edges together, melting the inner sealant layer to form a strong bond. These wheels also continue to guide the film tube.

This method creates a strong, continuous seal along the length of the film tube. For films with a pre-applied 'cold' adhesive, the wheels simply apply pressure without heat to activate the bond.

Performing the Transverse End Seal

Once the longitudinal seal is complete, the machine must seal the front and back ends of the package. This is done by a mechanism called the transverse sealing jaws. These jaws perform three actions at once: they seal the trailing end of the first pack, seal the leading end of the next pack, and cut the two packs apart.

Rotary sealing jaws are common in high-speed applications. They operate in a continuous circular motion. During their rotation, they make brief, tangential contact with the film tube to create the seals. A servo motor controls the rotation speed, ensuring the jaws meet the film at the precise gap between products. This method is incredibly fast, with some machines reaching speeds of up to 1000 packages per minute.

The jaws often have a serration pattern on their surface. This pattern is not just for looks. It maximizes sealing pressure, helping the sealant layer melt and flow into every crease. This ensures a strong seal and prevents leaks, which is especially important for challenging films or package shapes.

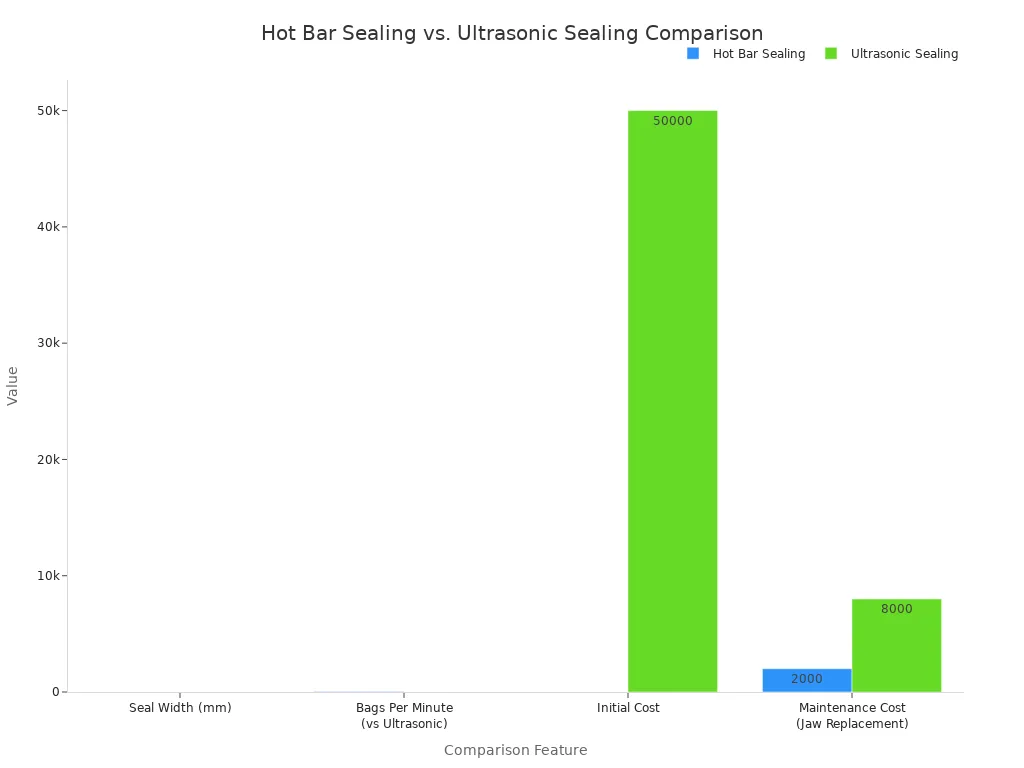

The sealing jaws use one of two primary technologies: hot bar sealing or ultrasonic sealing. Hot bar sealing uses heated bars that directly contact the film. In contrast, ultrasonic sealing uses high-frequency vibrations to generate heat and create the bond. Ultrasonic sealing is excellent for heat-sensitive products like chocolate but comes at a higher cost.

| Feature | Hot Bar Sealing (Heat Sealing) | Ultrasonic Sealing |

|---|---|---|

| Energy Use | Bars are heated constantly, consuming more energy. | Energy is consumed only during the sealing action. |

| Heat Sensitivity | Can affect heat-sensitive products. | Ideal for heat-sensitive items like produce or chocolate. |

| Sealing Through Product | Less effective if product gets in the seal area. | Can seal directly through product contamination. |

| Operation | Requires time for jaws to heat up before starting. | Jaws do not need time to heat up. |

The choice between these technologies depends on the product, film type, and production needs of the pillow packing machine.

Ultimately, the combination of the fin seal and the transverse end seals fully encloses the product, completing the "pillow" shape.

Stage 4: Final Cutting and Discharge

The final stage of the pillow packing process transforms the continuous, sealed tube of product into individual packages. This stage involves cutting the packs apart and moving them away from the machine for boxing or further handling. Precision is paramount here. The machine must cut in the exact right spot to create a professional, consistent final product.

The Integrated Cutting Mechanism

The cutting action happens at the same time as the transverse end sealing. The transverse sealing jaws contain an integrated cutting blade. As the jaws rotate to seal the ends of two adjacent packs, a knife extends to separate them. The speed of this mechanism must perfectly synchronize with the film feeding speed. The fin wheels, product feed, and cutter all work together. This ensures each cut occurs precisely in the sealed area between products. Advanced control systems, sometimes using laser technology, manage this synchronization to maintain accuracy at high speeds.

The blades themselves are specialized components designed for durability and precision.

- Packaging Machine Serrated Cutting Blades have excellent metal quality. Their serrated edges help grip and slice through various film types cleanly.

- Industrial Tungsten Steel Blades offer superior cost-effectiveness. They have a much longer lifespan, which reduces how often operators need to replace them.

Blade Maintenance is Key

Dull or dirty blades lead to poor cuts, torn packages, and machine jams. Regular maintenance is essential for clean cuts and optimal performance. A proper cleaning routine restores the blade and prevents rust.

A Three-Step Cleaning Process:

1.Soak: An operator applies a specialized cleaning solution to the blade. The blade soaks for 15-20 minutes to dissolve buildup.

2.Scrub: The operator uses a brush to gently scrub away any remaining residue from the teeth and surface.

3.Shine: The operator uses sawdust or compressed air to remove any leftover cleaner and ensures the blade is completely dry.

After cleaning, applying a blade lubricant reduces friction and protects the blade from rust. Regular inspection for chipped teeth or damage helps prevent bigger problems down the line.

Aligning Cuts with Eye-Mark Sensors

When the packaging film is pre-printed with logos, text, or graphics, the machine needs a way to know exactly where to cut. This is the job of the eye-mark sensor, also known as a photoelectric sensor. The film has small, rectangular marks printed in a consistent location, usually along one edge. These "eye-marks" create a high contrast against the film's background.

The sensor shines a light onto the film as it passes by. It detects the change in contrast when an eye-mark passes under it. This signal tells the machine's control system the exact position of the packaging artwork. The system then instructs the cutting blade to make its cut at the perfect spot between prints. This ensures the branding and product information are centered correctly on every package.

Before starting a production run, an operator must "train" the sensor to recognize the specific eye-mark.

1.The operator positions the film so the eye-mark is directly under the sensor.

2.They press a button on the sensor to teach it the "mark" condition.

3.Next, they move the film so a plain section is under the sensor.

4.They press the button again to teach it the "background" condition.

This simple calibration allows the sensor to reliably detect marks, even on different types of film. For consistent results, designers must follow specific rules when creating packaging artwork.

| Artwork Specification | Description | Purpose |

|---|---|---|

| Size | Typically 2–10 mm wide and 5–20 mm long. | Ensures the sensor can detect the mark at high speeds. |

| Color | High-contrast colors like black on a light film or white on a dark film. | Creates a clear signal for the sensor to read. |

| Placement | Positioned in a clean "eye mark track" free of other graphics. | Prevents the sensor from getting confused by other artwork. |

| Quiet Zone | A minimum 6 mm clear area reserved around each eye mark. | Guarantees no "print noise" interferes with detection. |

Discharging the Finished Package

Once the pillow pack is cut and sealed, it is a finished product. The final step is to move it away from the cutting area. This is handled by a discharge conveyor. This conveyor catches the packages as they fall from the cutting jaws and transports them to the next station. This could be a collection bin, a checkweigher, a cartoning machine, or a manual packing table.

The design of the discharge conveyor depends on the product and the next step in the production line. Common systems include:

·Elevator Belt Conveyors: These can lift packages and deposit them into large storage hoppers, which is useful in food packaging.

·Stainless Steel Timing Belts: These are common in pharmaceutical packaging, as they meet FDA standards for cleanliness.

·Table Top and MatTop Conveyors: These can handle single-file or mass flow of products, offering flexibility.

·Ergonomic Conveyors: Some systems, like the ATBI discharge conveyor, are designed to bring packages to a comfortable tabletop height for operators.

This final, simple step completes the journey from a flat roll of film to a perfectly sealed and finished product, ready for shipment.

A pillow packing machine achieves its high speed through the precise synchronization of four key stages. The forming, feeding, sealing, and cutting stages work together in a continuous flow. This integrated process rapidly transforms raw materials into finished packages. It is essential for the food, pharmaceuticals, and consumer goods industries.

Companies measure the machine's success by tracking key metrics, including:

·High throughput

·Low downtime and error rates

·Optimized material usage

This mechanical harmony makes the modern packaging line possible.

FAQ

What determines the speed of a pillow packing machine?

Servo motors are a key factor. They control the film feed, product spacing, and sealing jaws with high precision. The machine's overall design and the type of film also affect the maximum operational speed.

Can one machine handle different product sizes?

Yes, it can. Operators change the forming box to adjust the package width and height. They also adjust the infeed system and sealing jaws. Servo-driven machines store these settings as recipes for quick changeovers.

What happens if a product is in the seal area?

Product in the seal area can cause a weak or incomplete seal, which leads to leaks. Some machines use ultrasonic sealing technology. This technology can seal through minor product contamination, reducing waste and machine stops.

How does the machine handle fragile products?

The machine uses a gentle infeed conveyor system. The system's speed is synchronized with the film to prevent damage. Operators can adjust settings to ensure smooth handling. This protects delicate items like cookies or crackers during packaging.

Post time: Nov-14-2025