How to Determine Your Production Needs

Choosing the right machine starts with understanding your production volume. You need to know how many siomai you will sell each day. This number helps you pick a machine that meets your current needs and supports future goals.

Calculate Your Daily Sales Volume

First, you must estimate your daily sales. A new food stall or small restaurant often sells a specific number of siomai daily. Siomai cooks in under 5 minutes, which allows for fast service in busy areas. This speed helps you serve many customers quickly.

Use this table as a starting point for your estimates:

| Metric | Typical Daily Range |

|---|---|

| Daily Sales Volume (pieces) | 150 – 500 |

| Daily Orders | 50 – 100 |

| Customers Served (in busy areas) | 150 – 300 |

Plan for Future Business Growth

Your business will likely grow. Think about your five-year plan. Do you want to open another location? Will you sell frozen siomai? The frozen food market is projected to grow at a rate of 5.00% annually from 2025 to 2032. A machine with a higher capacity prepares you for this future demand. It prevents you from needing to buy a new machine too soon.

Pro Tip: Buying a machine that slightly exceeds your current needs is a smart investment. It gives you room to grow without interrupting your operations for an upgrade later.

Match Machine Type to Your Business Scale

Different businesses require different machines. Your choice of a siomai making machine should match your operational size.

- Startups: A manual or tabletop semi-automatic machine is perfect for testing the market. These are compact and cost-effective for smaller kitchens.

- Growing Businesses: As your demand increases, you may need a single-line automatic machine that produces around 3,000 pieces per hour.

- Large-Scale Operations: Food factories need high-volume, floor-standing models. For example, a double-line machine can produce 6,000 pieces per hour, meeting large-scale demand efficiently.

Key Features to Look for in a Siomai Making Machine

After you determine your production needs, you must examine the machine's features. The right features ensure your machine is efficient, safe, and easy to operate. You should focus on the type of automation, the material quality, and the physical size.

Semi-Automatic vs. Fully-Automatic Models

You will choose between two main types of machines: semi-automatic and fully-automatic. A semi-automatic machine requires some help from an operator. A fully-automatic machine handles the entire process by itself. Your choice depends on your budget, labor availability, and production volume.

This table compares the key differences to help you decide.

| Feature | Semi-Automatic Machines | Fully-Automatic Machines |

|---|---|---|

| Worker Input | An operator helps with tasks like loading ingredients. | Minimal human help is needed. |

| Production Volume | Good for small to medium businesses. | Ideal for large-scale mass production. |

| Initial Cost | Lower initial investment. | Higher initial investment. |

| Labor Costs | Reduces some labor but does not eliminate it. | Greatly reduces long-term labor costs. |

| Flexibility | Offers more control to customize products. | Provides less flexibility for custom changes. |

| Consistency | Delivers consistent results, better than manual work. | Produces extremely consistent and uniform siomai. |

A semi-automatic model gives you more hands-on control. It is a great starting point if you have a smaller budget. A fully-automatic siomai making machine maximizes your efficiency. It is the best choice for high-volume businesses aiming to lower labor expenses.

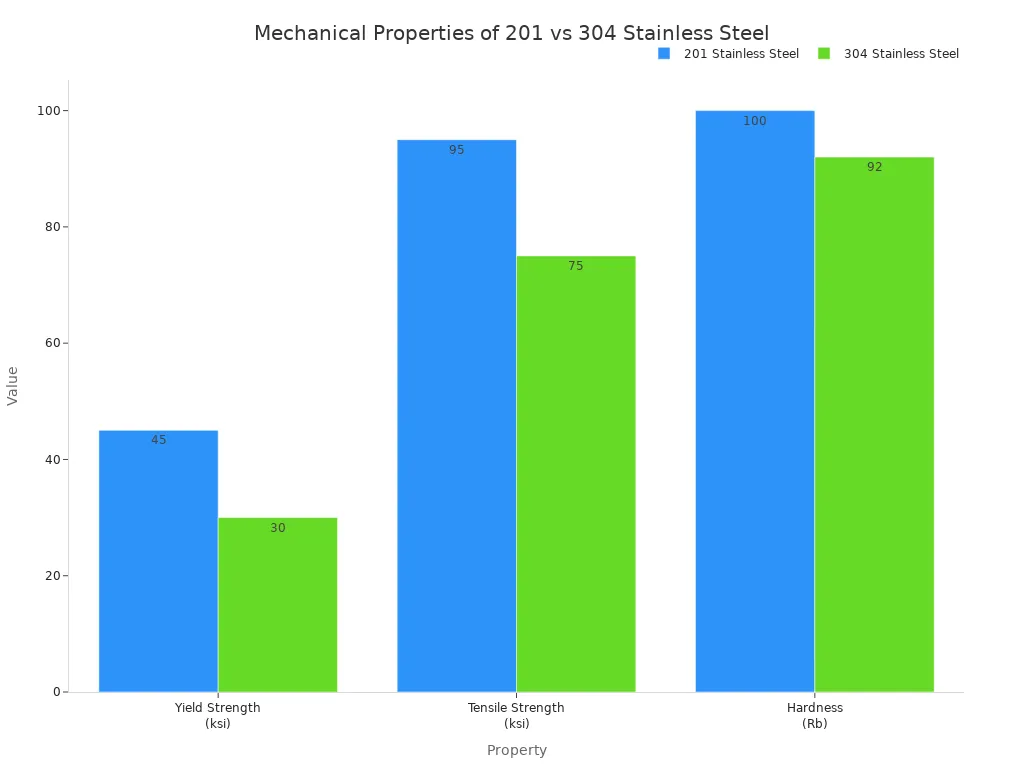

The Importance of 304 Stainless Steel

You must check the material of your machine. Look for models made with 304 stainless steel. This material is the standard for food-grade equipment because it is durable and resists rust. Cheaper machines might use 201 stainless steel, which is not as reliable.

Imagine leaving two metal cups damp overnight. A cup made of 304 steel would remain spotless. A cup made of 201 steel might show rusty spots. The 304 steel has more nickel and chromium. These elements create a protective layer that stops rust and corrosion, keeping your food safe.

Food Safety First: Your machine will be in constant contact with food ingredients. Using 304 stainless steel prevents rust from contaminating your siomai and ensures you meet health standards.

Besides rust resistance, 304 steel is also tougher. While 201 steel is technically harder, it is also more brittle and can dent or crack more easily. The 304 steel handles impacts better, making it more durable for a busy kitchen environment.

Measuring for Machine Size and Footprint

A siomai machine is a significant piece of equipment. You need to make sure it fits in your workspace. Before you buy, measure the area where you plan to put the machine. Remember to account for height, width, and depth.

Commercial machine sizes can vary greatly. A tabletop model will be much smaller than a floor-standing, high-capacity unit. Here are two examples of typical machine dimensions:

| Model | Dimension (mm) | Weight (kg) |

|---|---|---|

| Tabletop Model | 650 x 480 x 620 | 73 |

| Floor Model | 750 x 400 x 930 | 100 |

Pro Tip: Always leave extra space around the machine. You will need room for your staff to operate it safely, load ingredients, and perform regular cleaning and maintenance. A good rule is to allow at least two feet of clearance on all sides.

Prioritizing Ease of Use and Cleaning

Your siomai machine will become a daily workhorse in your kitchen. You need a machine that is simple to operate and quick to clean. Complex machines can slow down your team and increase the chance of mistakes. A difficult-to-clean machine creates food safety risks and adds to your labor costs.

An easy-to-use machine has clear controls and a straightforward process. Your staff should be able to learn its operation quickly. This reduces training time and ensures consistent production from day one. However, the most critical factor for daily operations is how easy the machine is to clean. You will clean your machine at the end of every shift, so this process must be fast and thorough.

Look for a siomai making machine with design features that simplify cleaning. Smart design makes maintenance much easier. Here are key features that allow for quick and effective cleaning:

- Tool-Free Disassembly: The best machines allow you to take apart the main components without any special tools. The stuffing filling assembly should have a quick-release design.

- Removable Parts: Key parts like the hopper and forming molds should be easy to unpick and wash separately. This allows you to clean every corner where food ingredients might hide.

- Specific Cleaning Zones: Some models are designed for targeted cleaning. For example, you can use compressed air to clean the dough pressing area. You can then wash the dumpling forming area with water.

A Clean Machine is a Safe Machine Your machine's components are in direct contact with food. Easy disassembly ensures you can remove all food residue. This prevents bacteria growth and guarantees you serve a safe, high-quality product to your customers every time.

All components should be made from food-grade stainless steel. This material is not only durable but also very simple to take apart, clean, and maintain. It resists stains and does not harbor bacteria, making your cleaning process more effective and efficient.

How to Make a Smart Investment

Buying a machine is a big step for your business. You need to think beyond the initial price tag. A smart investment considers the machine's price, its long-term running costs, and the support you get from the manufacturer. This approach ensures your machine is a valuable asset, not a costly problem.

Typical Price Ranges for Siomai Machines

You can find a machine that fits your budget. The price depends on the machine's features and capacity. Semi-automatic models for small businesses typically cost between $1,600 and $3,500. You can find some reliable options for under $2,000. Fully-automatic machines have a higher price but offer greater production speed and require less labor.

Calculating the Total Cost of Ownership

The sticker price is only one part of the total cost. You must also plan for other expenses to understand your full investment. This is called the total cost of ownership.

Consider these additional costs:

- Shipping and Handling: Getting the machine to your location.

- Installation: Some machines may need professional setup.

- Energy Use: Commercial machines often use between 1.2 and 7.5 kWh. This affects your monthly electricity bill.

- Maintenance: Regular upkeep and replacement parts.

Why Warranty and After-Sales Support Matter

Your machine will work hard every day. A good warranty protects you if something goes wrong. Many experts recommend looking for suppliers that offer at least a 2-year warranty. Strong support from the manufacturer is just as important.

Peace of Mind is Priceless Good after-sales support means you can get help quickly. This prevents long downtimes that could hurt your sales and reputation.

Look for a siomai making machine with a warranty that includes:

- Free replacement for broken or defective parts.

- Coverage for non-human damage.

- Lifetime technical support for future questions or upgrades.

Your Quick-Start Checklist for Choosing a Machine

This checklist breaks down the selection process into simple, actionable steps. You can use it to stay organized and make a confident choice for your business.

Step 1: Define Your Capacity (Pcs/Hour)

Your first step is to decide how many siomai you need to make each hour. This number connects directly to your sales goals and business size. A small food stall has very different needs than a large food factory. Commercial machines offer a wide range of production speeds.

For example, some popular models show how capacity can scale:

| Model No. | Capacity (pcs/hr) |

|---|---|

| P720 | 6,000 |

| HSM-600 | 5,000 - 6,000 |

| HSM-900 | 9,000 |

Choosing a machine with the right capacity ensures you can meet customer demand without overspending on a machine that is too powerful for your needs.

Step 2: Set Your Total Budget

Next, you must create a complete budget. Your budget should cover more than just the machine's sticker price. You need to account for the total cost of ownership, which includes shipping, installation, and potential training.

Many businesses use special budget templates to track these expenses. Common templates include:

- Restaurant Construction Budget Template: Helps manage costs for new builds, including kitchen equipment.

- Restaurant Capital Budget Template: Tracks major investments like new machinery and furniture.

- Restaurant Renovation Budget Template: Manages expenses for upgrading an existing space.

Planning for all costs helps you avoid surprises and ensures your investment is financially sound.

Step 3: Compare 3-5 Machine Models

With your capacity and budget defined, you can start comparing specific machines. Do not just pick the first one you see. Research and compare three to five different models from reputable suppliers.

Pro Tip: Create a simple chart to organize your findings. List each model and compare key features side-by-side, including:

- Price

- Capacity (pcs/hour)

- Material (look for 304 stainless steel)

- Dimensions and weight

- Warranty and after-sales support

This method helps you see the pros and cons of each option clearly. It makes your final decision much easier.

Step 4: Verify Build Quality and CE Certification

You must check the machine's quality and safety certifications. A well-built machine lasts longer and works better. Look for the CE mark, which shows the machine meets European Union safety standards. This mark is a good sign of quality, even if you are not in Europe.

However, you need to make sure the CE certification is real. Some sellers might use fake documents. You can verify the authenticity of a CE certificate yourself.

- Check the document. Look for spelling errors, strange formatting, or signs it was changed.

- Confirm with the manufacturer. Use the contact information on their official website to ask about the product's compliance.

- Look for the CE mark. The mark should be on the machine or its packaging. It must match the information on the certificate.

- Compare product details. Make sure the model number and specifications on the certificate match the machine you want to buy.

- Ask for supporting documents. Request to see test reports or technical files that prove the certification is valid.

Taking these steps helps you confirm that the machine is safe and built to a professional standard.

Step 5: Inquire About Warranty and Support

Your final step is to ask about the warranty and after-sales support. A good warranty protects your investment. Strong customer support saves you from long downtimes if a problem occurs. Do not be afraid to ask the supplier detailed questions before you buy.

Get It in Writing! Always ask for the warranty policy in a written document. This ensures you and the supplier have a clear understanding of the terms.

Here are key questions you should ask every potential supplier:

- What types of warranties do you offer?

- How long does the warranty last?

- What is the process for filing a warranty claim?

- What is covered under the warranty, and what is not?

- Are there any exclusions or limitations I should know about?

- How are repairs handled if the machine fails?

- Who will perform the warranty work?

A supplier who answers these questions clearly is more likely to provide reliable support after your purchase.

You must balance capacity, features, and your budget to pick the best machine. Your investment can pay for itself quickly. Many similar food machines see a return in 18 to 24 months.

Use the quick-start checklist in this guide to make a confident choice. A well-chosen siomai machine is a reliable asset. It supports your business's quality and growth from day one.

FAQ

Can a machine make siomai as good as handmade ones?

Yes. A machine provides excellent consistency in size, shape, and filling weight. This ensures every siomai you sell meets the same high standard. Your customers will enjoy a uniform product every time, which is difficult to achieve by hand.

How hard is it to operate a siomai machine?

Modern siomai machines are designed for easy use. You will find they have simple controls and a clear operating process. Most suppliers also offer training videos or support. Your team can learn to operate the machine quickly, often within a day.

How often do I need to clean the machine?

You must clean your siomai machine daily. A full cleaning is necessary after every production shift. This practice is essential for food safety. It prevents bacteria from growing and ensures you serve a safe, high-quality product to your customers.

How long does it take to get my money back on a siomai machine?

You can often see a return on your investment in 18 to 24 months. The exact time depends on your sales volume and profit margins. A machine's efficiency helps you produce more and serve customers faster, speeding up your return.

Post time: Nov-14-2025