Automation and Speed: The Primary Cost Drivers

A machine's level of automation and its production speed are the most significant factors that determine its price. A business must decide between paying more upfront for automation or paying more over time for manual labor. This choice directly shapes the final liquid packing machine price.

Manual vs. Semi-Automatic vs. Fully-Automatic

The journey from manual to fully-automatic operation shows a clear increase in cost and capability.

·Manual Fillers: These simple machines require an operator for every step. The operator places the container, activates the fill, removes the container, and closes it. Manual liquid fillers can save businesses approximately $2,000 to $5,000 in initial expenses compared to semi-automatic versions. They are best for startups or very small-batch production.

·Semi-Automatic Fillers: These machines automate the filling process but still need an operator to place and remove containers. They offer a balance between speed and cost, making them popular for growing businesses.

·Fully-Automatic Fillers: These systems handle the entire process without human help. They use conveyors to move containers, sensors to position them, and automated mechanisms for filling and capping. Fully automatic machines typically cost about three to five times more than semi-automatic models.

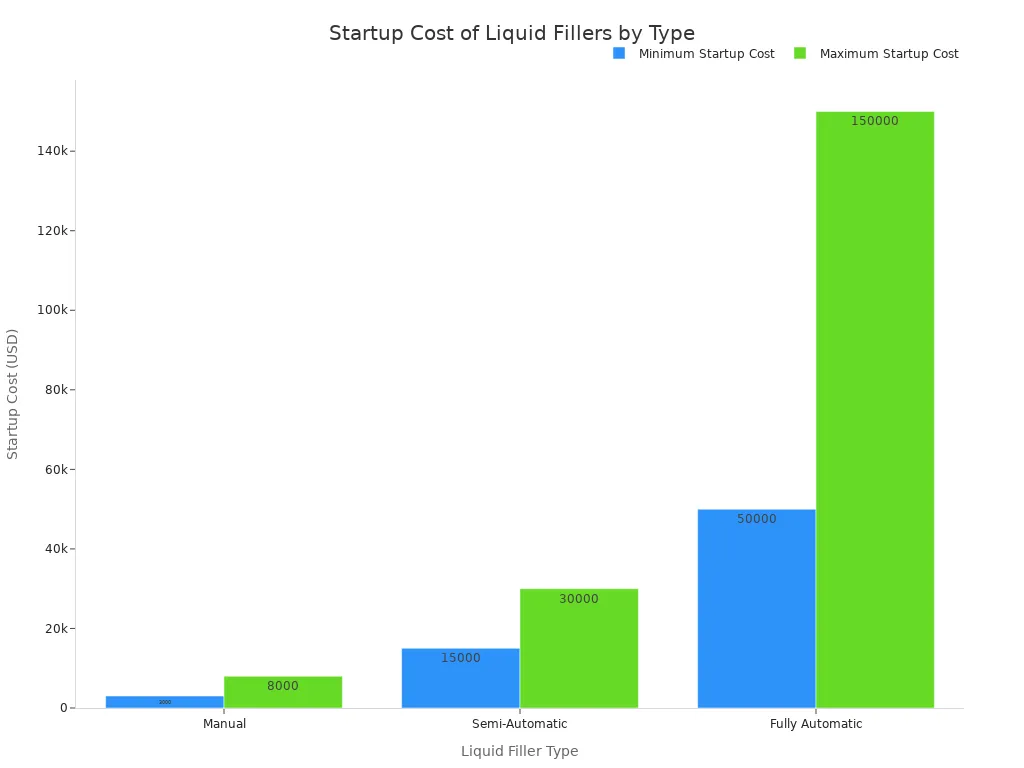

The initial investment varies significantly across these types.

| Feature | Manual | Semi-Automatic | Fully Automatic |

|---|---|---|---|

| Startup Cost | $3k–$8k | $15k–$30k | $50k–$150k |

A Note on ROI: While a fully-automatic machine has a high initial cost, its long-term value is often much greater. Integrating automation in liquid packing machines boosts production rates and minimizes labor costs. A true return on investment (ROI) analysis reveals how these machines pay for themselves over time.

Automated systems provide undeniable long-term cost-effectiveness. They offer several key advantages:

·Lower labor costs

·Increased production speed and higher output

·Reduced material waste and improved accuracy

·Better overall product quality

·Lower maintenance needs compared to older equipment

Production Capacity and Speed (Units Per Minute)

Production speed is often measured in Units Per Minute (UPM) or Containers Per Minute (CPM). A machine's price directly relates to its speed. Quicker liquid filling machines with higher outputs always cost more than slower equipment.

This price increase happens for a few key reasons. Faster machines need more complex engineering, a greater number of moving parts, and superior quality materials to handle the stress of high-speed operation. Think of it like a race car versus a family car. Both provide transportation, but the race car's speed requires a much more advanced and expensive design.

Number of Filling Nozzles

The number of filling nozzles on a machine is a primary factor in its speed and cost. A machine with a single nozzle can only fill one container at a time. A machine with eight nozzles can fill eight containers in the same period.

·More Nozzles = Higher Speed: Each additional nozzle directly increases the machine's potential UPM.

·More Nozzles = Higher Cost: Adding nozzles increases the price. This is not just for the nozzles themselves. It also requires a more complex product delivery system (manifold), more sophisticated electronic controls, and a larger, more robust machine frame to support it all.

A business must balance its need for speed with its budget. A machine with two or four heads might be perfect for a medium-sized operation, while a large-scale manufacturer might need a machine with 12 or more nozzles to meet demand.

How Product and Container Specs Impact Liquid Packing Machine Price

The characteristics of the product and its container are just as important as speed. A machine must be engineered to handle a specific liquid and package. This customization is a major factor in the final liquid packing machine price. Mismatched technology leads to inefficiency, product waste, and potential damage to the machine or containers.

Matching Filling Method to Your Liquid

Not all liquids are the same. A machine designed for water will struggle with a thick cream or a chunky salsa. The filling technology must match the product's viscosity (thickness), tendency to foam, and whether it contains particulates. Each filling method uses different components and engineering, directly influencing cost.

·Overflow Fillers: These are ideal for thin, free-flowing liquids like water or window cleaner. They fill each container to the same visual level, which is great for clear bottles. They are often a cost-effective choice for these types of products.

·Piston Fillers: These are versatile and can handle a wide range of viscosities, from thin liquids to thick pastes like peanut butter. They are volumetric, meaning they deliver a precise amount of product each time. Their flexibility makes them popular but can increase their cost compared to simpler fillers.

·Pump Fillers: These use a pump (like a lobe, gear, or progressive cavity pump) to move the product. They are excellent for very thick products and can be configured for a wide range of fill volumes. The type and size of the pump needed will affect the machine's price.

·Gravity Fillers: This is one of the most economical options. It works best for low-viscosity, non-foaming liquids. The product is held in a tank above the fill heads, and gravity does the work.

Required Fill Accuracy and Precision

Fill accuracy is critical. Overfilling gives away free product, cutting into profits. Underfilling can lead to unhappy customers and legal issues. The level of precision required from a machine is a significant cost factor. Standard machines may have an accuracy of +/- 1%, but some industries require much tighter tolerances.

Achieving high precision often involves advanced technology like servo-driven systems. Servo-driven piston fillers use motors to control the filling process with extreme accuracy. Unlike older pneumatic systems, they offer superior control over fill speed and volume. This technology uses a closed-loop control system that provides constant feedback, ensuring positioning accuracy of up to 99%.

This precision nearly eliminates the margin of error. The result is consistent, exact fills that reduce product waste from drips or overflows. While the initial investment is higher, the cost savings are substantial.

The Value of Precision: The precision of servo motors leads to less product waste, which translates directly into cost savings. These systems are also highly energy-efficient, with some data showing energy cost reductions of up to 40%. Fewer moving parts also mean less mechanical wear, leading to lower maintenance costs and a longer machine life.

Container Type, Size, and Shape

The machine must be built to handle the product's container. A simple round bottle is much easier to manage than an oddly shaped one. The machine's complexity and cost increase based on the container's specifications.

Key container factors include:

1.Material: Glass bottles are heavy and fragile. They require gentler handling than lightweight, durable plastic containers.

2.Shape: Round containers are easy to move and align on a conveyor. Square, rectangular, or irregular shapes may require special pucks or timing screws to hold them securely, adding to the machine's cost.

3.Size: A machine designed for small vials cannot handle large jugs. A machine with the flexibility to handle a wide range of container sizes needs adjustable guide rails and other change parts, which increases its price.

The table below shows how container features influence machine design and cost.

| Container Feature | Machine Requirement | Cost Impact |

|---|---|---|

| Standard Round Bottle | Simple guide rails | Low |

| Irregular Shape | Custom pucks or timing screws | High |

| Multiple Sizes | Adjustable rails, change parts | Medium to High |

| Glass Material | Slower speeds, gentle handling | Medium |

Ultimately, a machine must be tailored to the product and package. This ensures smooth operation and a high-quality finished good.

Construction Quality, Durability, and Compliance

The materials and engineering behind a machine protect both the product and the investment. A machine's build quality, its suitability for the production environment, and its physical size are key components of its final cost. These factors ensure long-term reliability and safety.

Machine Build Materials and Finish

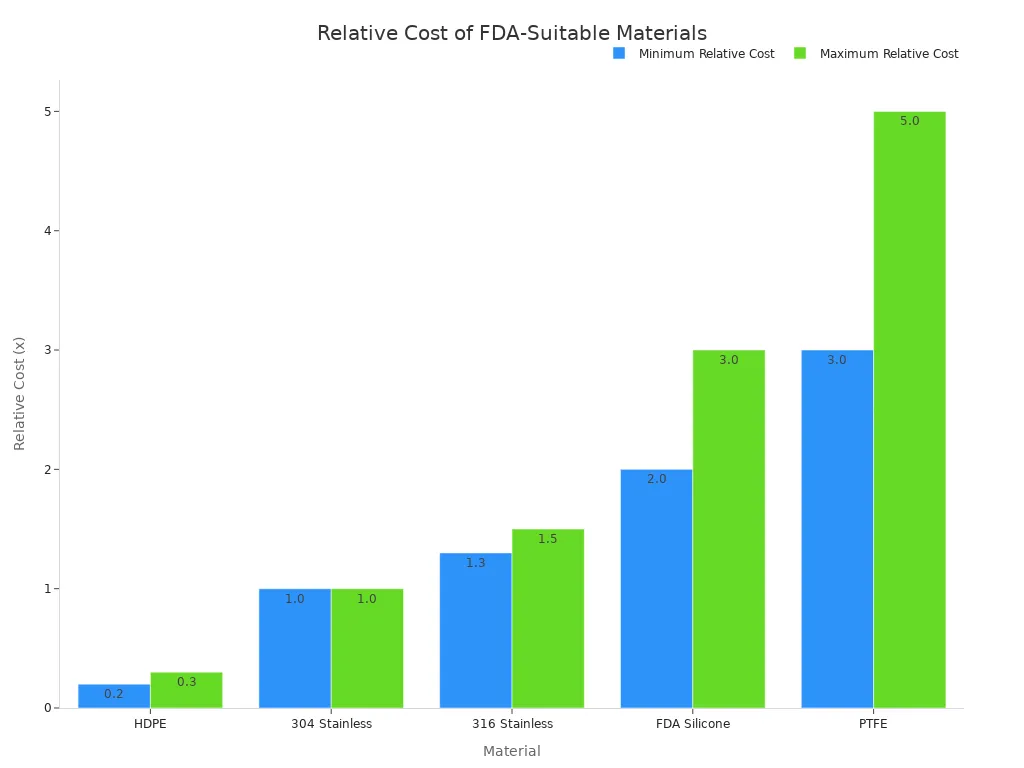

The materials used to build a liquid filler are fundamental to its price and function. Most machines use stainless steel for its durability and corrosion resistance. However, the grade of steel and its finish create significant cost differences.

For food and pharmaceutical applications, a smooth, polished surface is essential for hygiene. Rough surfaces can trap bacteria and product residue.

Why Finish Matters: Processes like electropolishing create an ultra-smooth, non-stick surface. This finish prevents microscopic pits where bacteria could grow, enhances corrosion resistance, and makes the machine much easier to clean and sterilize. This level of finish adds to the machine's cost but is non-negotiable for sanitary production.

Sanitary vs. Hazardous Environment Designs

A machine's design must comply with industry standards. A filler for industrial chemicals has different requirements than one for pharmaceuticals. Machines built for sanitary environments must follow strict guidelines from bodies like the FDA to prevent contamination.

This involves specific design choices that increase cost:

·Material Selection: High-acid foods or sterile drugs require 316 stainless steel, which is more expensive than the standard 304 grade.

·Hygienic Design: Machines must be free of cracks or crevices where microbes could hide. All parts must be easily accessible for cleaning.

·Washdown Protection: Equipment in wet environments needs a high IP rating (e.g., IP65 or higher) to protect electronics from high-pressure water jets, adding to the cost.

The required materials for sanitary designs vary widely in cost.

Meeting these standards significantly raises the liquid packing machine price, but it is essential for producing safe, compliant products.

Machine Size and Footprint

The physical size of a machine also influences its cost. Larger machines require more raw materials and more complex engineering, making them more expensive to build. The machine's footprint also has indirect costs. A large machine takes up valuable floor space in a facility. Smaller footprint machines are often easier and less costly to ship and install, especially when space is a concern.

Customization, Support, and Total Cost of Ownership

A machine's initial purchase price is only part of the story. Customization options, ongoing tooling needs, and manufacturer support all play a role in the total cost of ownership. These factors influence the long-term value and operational efficiency of the equipment.

Flexibility for Multiple Products or Containers

Businesses that package various products or use different container sizes need flexible machines. This adaptability adds to the initial cost but can save significant money over time. Machines built for flexibility have advanced features that allow for quick and easy changeovers.

Key features that increase a machine's flexibility include:

·Programmable Logic Controllers (PLCs) with memory to store multiple product recipes.

·Easily adjustable guide rails and conveyor systems.

·Servo-driven controls for fast container height adjustments.

·Fully adjustable nozzle spacing to fit different container widths.

This built-in versatility reduces downtime between production runs, making the operation more efficient.

Cost of Change Parts and Tooling

When a machine needs to handle a new container, it often requires new change parts or tooling. The cost of these parts depends on their complexity. A simple round bottle requires standard, inexpensive guide rails. However, a unique bottle shape with sharp angles or deep undercuts demands custom-designed tooling, which is much more expensive.

A Note on Custom Tooling: The one-time expense for custom molds and tooling is spread across the entire production order. A higher initial tooling cost will only lead to a lower price per bottle at very large production volumes. Early collaboration between designers and engineers is crucial to avoid costly surprises.

After-Sales Support and Warranty

Reliable support from the manufacturer is a critical, though often overlooked, part of the liquid packing machine price. A strong support package ensures the machine runs smoothly and minimizes costly downtime. Most manufacturers offer a standard one-year warranty that covers manufacturing defects and faulty parts.

Support packages can include:

·Technical Support: Expert technicians available by phone or online chat to troubleshoot issues.

·On-Site Service: Engineers who can visit a facility for complex repairs or installation.

·Operator Training: Programs to teach staff how to operate and maintain the equipment properly.

A comprehensive warranty and accessible support provide peace of mind and protect the investment, contributing to a lower total cost of ownership.

A liquid packing machine's price is a calculated sum of its technology, materials, and speed. The right machine provides the best value, not just the lowest cost. A higher initial investment often leads to a lower total cost of ownership. Efficient machines built with quality materials experience fewer breakdowns and require less maintenance, saving money over time. A food company, for example, cut downtime by 70% after investing in a machine redesign.

Get the Right Quote: To understand the true cost, a business must consult a specialist. Be ready to provide key details like product viscosity, container type, and desired production speed for an accurate quote.

FAQ

What is the biggest factor affecting machine price?

The level of automation is the biggest factor. A fully-automatic machine has a higher initial price than a manual or semi-automatic model. It provides greater speed and reduces long-term labor costs, improving efficiency.

Does the product's viscosity affect the price?

Yes, a product's viscosity is very important. Thick liquids like creams need powerful piston or pump fillers. Thin liquids can use simpler gravity fillers. The required filling technology directly impacts the machine's final cost.

Is the cheapest machine the best choice for a startup?

Not always. The cheapest machine may have higher labor needs and less reliability. A business should consider the total cost of ownership. This includes maintenance, downtime, and labor, not just the initial purchase price.

What information is needed for an accurate quote?

A specialist needs key details for a quote. A business should provide its product's viscosity and characteristics. It must also include the container's type, size, and shape, along with the desired production speed.

Post time: Dec-05-2025