Top China Manufacturer of Brick Pallet Packing Machines for Optimal Efficiency

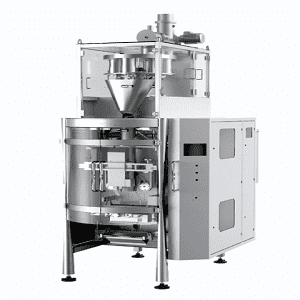

When I thought about enhancing my packaging efficiency, the Brick Pallet Packing Machine caught my eye. Manufactured in China, this machine is designed to streamline the entire palletizing process, ensuring your bricks are stacked securely for transport. I appreciate how easy it is to operate, even for teams new to automation. The robust construction guarantees durability, plus its compact design fits perfectly in any manufacturing environment. Finding a reliable manufacturer was crucial for me, and I was pleased to note that this machine comes with excellent support and spare parts availability. It’s more than just a packing machine; it’s an investment in productivity that I can confidently recommend. If you're looking to elevate your brick production line, this Brick Pallet Packing Machine might just be the solution you need. You’ll notice a significant improvement in speed and efficiency, making your operations more profitable.

Brick Pallet Packing Machine Winning in 2025 More Than a Supplier - A Partner

The landscape of industrial automation is evolving rapidly, and the brick pallet packing machine is at the forefront of this change. As we look towards 2025, businesses are not merely searching for suppliers; they are seeking true partners who understand their unique needs and can provide comprehensive solutions. This shift emphasizes the importance of collaboration in enhancing operational efficiency, reducing costs, and improving product quality. In an era where efficiency is paramount, investing in advanced machinery like the brick pallet packing machine can significantly streamline production processes. These machines not only automate the packing process but also ensure uniformity and precision, resulting in higher throughput and lower labor costs. Moreover, as sustainability becomes a focal point for businesses globally, the innovative designs and energy-efficient operations of these machines support eco-friendly practices, making them an attractive option for environmentally conscious companies. Building strong partnerships can foster innovation and drive success. By choosing to work with equipment manufacturers that prioritize customer engagement and offer tailored solutions, businesses can navigate the complexities of the market effectively. These partnerships enhance adaptability, ensuring that enterprises can swiftly respond to changing demands and technological advancements, ultimately positioning them as leaders in their respective industries by 2025 and beyond.

Brick Pallet Packing Machine Winning in 2025 More Than a Supplier - A Partner

| Feature | Description | Benefits | Future Innovations |

|---|---|---|---|

| Automation | Advanced automated systems for efficient packing. | Increased speed and reduced labor costs. | Integration with AI for smarter operations. |

| Flexibility | Ability to work with various brick sizes and shapes. | Adaptable solutions for different production needs. | Future modular designs for enhanced customization. |

| Energy Efficiency | Low energy consumption technology in operation. | Cost savings on energy bills and environmental benefits. | Research into renewable energy integration. |

| User-Friendly Interface | Intuitive controls and touchscreen operations. | Easier training for operators and less downtime. | AI-driven support for troubleshooting. |

| Durability | Robust construction designed for heavy usage. | Longer lifespan and reduced maintenance costs. | Materials science advancements for stronger components. |

Related Products