Top China Manufacturer of Carton Tying Strapping Machines for Efficiency

As a manufacturer of top-quality carton tying strapping machines in China, I'm excited to share how our machines can elevate your packaging process. Our strapping machines are designed for efficiency and reliability, making them ideal for businesses that require secure and fast packaging solutions. With our technology, you can minimize packaging time and reduce material costs, ensuring that your products are shipped safely and effectively. What sets our machines apart is their user-friendly interface and customizable settings, allowing you to tailor the strapping process to your specific needs. Our dedicated team is ready to provide support and ensure you get the most out of your investment. Whether you’re a small business or a large-scale operation, our carton tying strapping machines can help streamline your workflow and enhance productivity. Join the countless satisfied clients who trust our equipment to meet their strapping needs with confidence!

Carton Tying Strapping Machine Factory Dominates

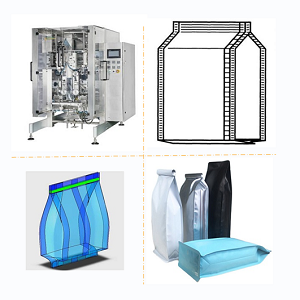

In today’s fast-paced manufacturing landscape, the efficiency and reliability of packaging solutions are paramount for businesses looking to enhance productivity. A leading player in the industry has set the standard with its innovative carton tying strapping machines, designed for a wide array of applications. These machines not only improve the speed of the packaging process but also ensure that products are securely tied, preventing damage during transit. The strapping technology employed in these machines is engineered for versatility, capable of handling various materials, including plastic and steel straps. This flexibility allows manufacturers to meet diverse packaging needs while maintaining high operational efficiency. Additionally, the machines are equipped with user-friendly controls and robust safety features, making them suitable for both small-scale operations and large manufacturing facilities. As global sourcing becomes more competitive, investing in high-quality strapping machines is essential for companies looking to optimize their supply chains. By integrating advanced strapping solutions into their processes, businesses can achieve significant cost savings, improve shipping reliability, and enhance customer satisfaction. These advantages position manufacturers to thrive in an increasingly demanding market, reinforcing their commitment to excellence in packaging solutions.

Carton Tying Strapping Machine Factory Dominates

| Model | Features | Speed (Cycles/min) | Power (Kw) | Weight (Kg) | Dimensions (mm) |

|---|---|---|---|---|---|

| Model A | Automatic, Compact Design | 30 | 1.5 | 200 | 800 x 600 x 400 |

| Model B | Heavy Duty, Multi-Position | 25 | 2.2 | 250 | 900 x 700 x 500 |

| Model C | Smart Control, Easy Maintenance | 35 | 1.8 | 220 | 850 x 650 x 450 |

| Model D | High Efficiency, Low Noise | 40 | 1.5 | 230 | 870 x 670 x 470 |

Related Products