Essential Oil Bottle Packing Machine for Wholesale Manufacturers

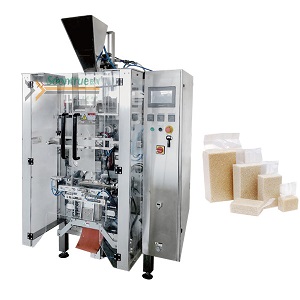

Are you in the market for an efficient and reliable Essential Oil Bottle Packing Machine? I understand how important it is to streamline your production process while maintaining high quality. This machine is designed specifically for wholesale manufacturers who prioritize both speed and precision. With its user-friendly interface and robust build, it can handle a variety of bottle sizes and shapes, making it perfect for your essential oil products. I've seen firsthand how it boosts efficiency, allowing for faster turnaround times and reducing labor costs. Plus, its compact design means it won’t take up too much space in your facility. The maintenance is easy, ensuring you spend less time on repairs and more on production. Whether you’re a small business or looking to scale, this Essential Oil Bottle Packing Machine is tailored for manufacturers aiming to elevate their operations. Let’s enhance your packaging line with this state-of-the-art solution!

Essential Oil Bottle Packing Machine Service Your End-to-End Solution

In the ever-evolving landscape of essential oil production, efficiency and precision are paramount. As global demand for essential oils continues to rise, the necessity for advanced machinery that can handle every stage of the packaging process has never been more critical. A state-of-the-art essential oil bottle packing machine offers a comprehensive end-to-end solution that meets the diverse needs of manufacturers worldwide. These machines not only streamline the filling and capping processes but also ensure that the integrity and quality of the oils are preserved throughout packaging. Modern packing machines are designed with flexibility in mind, allowing for the accommodation of various bottle sizes and shapes. This adaptability is essential for businesses looking to diversify their product offerings while maintaining high production standards. Additionally, integrating automation into the packaging process minimizes human error and increases throughput, making it easier for companies to keep up with market demands and maintain a competitive edge. Investing in an efficient essential oil bottle packing machine can lead to significant long-term benefits. By optimizing production lines, manufacturers can reduce operational costs and improve overall productivity. Moreover, these machines are designed with user-friendly interfaces and require minimal maintenance, allowing businesses to focus on what they do best—delivering high-quality essential oils to consumers around the globe. In a market that values both quality and innovation, having the right packaging solution can set companies apart and pave the way for growth and success.

Essential Oil Bottle Packing Machine Service Your End-to-End Solution

| Machine Model | Production Speed (bottles/min) | Bottle Size (ml) | Power Requirement (kW) | Dimensions (mm) | Weight (kg) | Features |

|---|---|---|---|---|---|---|

| EO-100 | 20 | 10-50 | 1.5 | 1200 x 800 x 1500 | 300 | Fully automatic, easy to operate |

| EO-200 | 30 | 5-100 | 2.0 | 1500 x 900 x 1600 | 350 | High precision, low energy consumption |

| EO-300 | 40 | 15-200 | 2.5 | 1800 x 950 x 1700 | 400 | User-friendly interface, quick setup |

Related Products