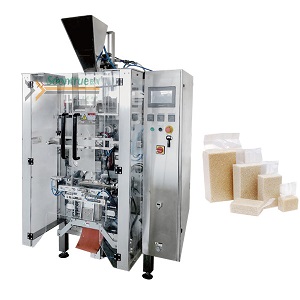

Wholesale Filling Machines for Powder and Grain - Top Manufacturers

When it comes to sourcing efficient solutions for your production line, our Filling Machine for Powder and Grain stands out. Designed for wholesalers and manufacturers, this machine is tailored to handle various powders and grains with precision and speed. I appreciate its versatility, as it easily accommodates different product types, helping reduce downtime and maximize productivity. You’ll find it easy to operate, with user-friendly controls that simplify the filling process. Our machine is built with durability in mind, ensuring it withstands the rigors of daily use. Purchasing in bulk is not just beneficial for pricing; it helps streamline your operations, making this filling machine a smart investment for any manufacturer looking to elevate their production capabilities. Explore our competitive wholesale options today, and let’s take your business to the next level with reliable filling solutions.

Filling Machine For Powder And Grain Exceeds Industry Benchmarks From Concept to Delivery

In today's fast-paced manufacturing landscape, the demand for efficient and reliable filling machines for powders and grains has never been greater. The right machinery not only enhances productivity but also ensures precision and minimizes waste. As companies strive to keep up with market demands, investing in advanced filling solutions that exceed industry benchmarks becomes a critical factor in maintaining competitiveness. Our innovative filling machines are designed to cater to a wide range of industries, providing versatility and adaptability to different materials, from fine powders to larger grain sizes. With a commitment to excellence, we have engineered our systems to optimize every stage of the filling process, from concept to delivery. Our machines are equipped with cutting-edge technology that guarantees accurate measurements and seamless integration into existing production lines, ensuring that your operations are not only efficient but also scalable for future growth. Furthermore, we understand that cost efficiency is as important as performance. Our filling machines are built with durability in mind, allowing for long-term use with minimal maintenance, which translates into lower operational costs. By choosing a high-performance filling solution, businesses can significantly enhance their production efficiency, meet stringent quality standards, and ultimately drive profitability in an increasingly competitive environment.

Filling Machine For Powder And Grain Exceeds Industry Benchmarks From Concept to Delivery

| Feature | Specification | Performance Metric | Industry Benchmark |

|---|---|---|---|

| Max Filling Capacity | 2000 kg/h | Filling speed | 1500 kg/h |

| Accuracy | ± 0.5% | Filling accuracy | ± 1% |

| Power Consumption | 2 kW | Power efficiency | 3 kW |

| Control System | PLC with HMI | Ease of use | Manual control |

| Dimensions | 1500 x 800 x 1800 mm | Space efficiency | 1800 x 1000 x 2000 mm |

| Maintenance Interval | 500 hours | Downtime | 300 hours |

Related Products