Fully Automatic Bean Food Packaging Machine with 10 Heads Weigher - China Manufacturer

When it comes to efficiently packaging food products, I can't recommend the Fully Automatic Bean Food Packaging Machine with a 10 Heads Weigher enough. This machine is designed with precision and reliability in mind, ensuring that every package is perfectly weighed and sealed. Sourced from a reputable manufacturer in China, I’ve experienced firsthand its outstanding performance in high-volume settings. The user-friendly interface makes it easy to operate, while the durability of the materials ensures that it stands the test of time. Whether you're in the bean industry or looking to expand your packaging capabilities, this machine delivers unmatched speed and accuracy. Plus, its versatility means it can handle various food types, not just beans. Investing in this equipment means setting your business up for success, improving efficiency, and ultimately boosting your profit margins. Don’t miss the chance to enhance your packaging line!

Fully Automatic Bean Food Packaging Machine 10 Heads Weigher Factory-Direct Excellence More Than a Supplier - A Partner

In the ever-evolving landscape of food production, the demand for efficiency and precision has never been more pronounced. The Fully Automatic Bean Food Packaging Machine, equipped with a state-of-the-art 10 Heads Weigher, stands at the forefront of this evolution. This innovative machine not only offers remarkable accuracy in weighing but also streamlines the packaging process, allowing businesses to meet the growing demands of the global market while minimizing labor costs and reducing waste. Choosing a partner in machinery manufacturing is crucial for companies aiming for operational excellence. Unlike traditional suppliers, a true partner understands your unique requirements and works collaboratively to enhance your production capabilities. With a commitment to cutting-edge technology and continuous improvement, businesses can trust that they will receive not just machinery, but a comprehensive solution tailored to their specific needs. Investing in fully automatic packaging systems signifies a step towards modernization and efficiency. With the right technology, businesses can boost their productivity, ensure product quality, and elevate their competitiveness in the marketplace. The journey towards operational excellence starts with selecting the right machinery partner, one who not only delivers high-quality products but also supports you in achieving your long-term business goals.

Fully Automatic Bean Food Packaging Machine 10 Heads Weigher Factory-Direct Excellence More Than a Supplier - A Partner

| Feature | Description | Benefit |

|---|---|---|

| Weighting Technology | 10 heads weigher for precise measurement | Ensures accurate packaging and reduces waste |

| Speed | Up to 60 bags per minute | High efficiency for large volume production |

| User-Friendly Interface | Touchscreen control panel | Easy to operate, reducing training time |

| Material Compatibility | Suitable for various bean types and granules | Versatile application across different products |

| Safety Features | Automatic shutdown in case of errors | Increases safety for operators and the machine |

| Energy Efficiency | Low power consumption | Reduces operational costs |

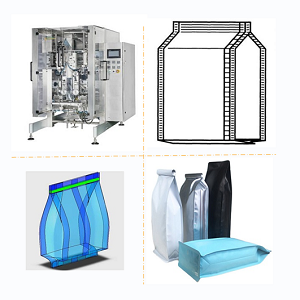

Related Products

.jpg)