Wholesale Honey Packing Equipment from Leading Manufacturers

When it comes to honey packing equipment, I know the importance of efficiency and reliability in your operations. We specialize in providing top-notch, wholesale solutions for manufacturers who are serious about quality. Our equipment is designed specifically to ensure that every drop of honey is packed with precision, preserving its natural goodness and flavor. I understand that as a B2B purchaser, you need machinery that can handle high volumes while keeping consistency in every batch. That’s why our honey packing systems are not just versatile but also easy to operate and maintain. Investing in our equipment means you're choosing a partner who values your business as much as you do, optimizing your packaging process to meet demands without compromise. Let’s enhance your honey production together and take your manufacturing capabilities to the next level!

Honey Packing Equipment For the Current Year Service Backed by Expertise

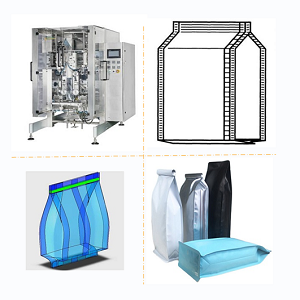

In the ever-evolving landscape of the honey packing industry, having the right equipment is essential for ensuring efficiency and quality. This year's advancements in honey packing machinery showcase a commitment to innovation and expertise. As global demand for high-quality honey continues to rise, the need for reliable packing solutions has never been more critical. Our latest range of honey packing equipment integrates cutting-edge technology with user-friendly design, ensuring that businesses can streamline their production processes while maintaining the integrity of their products. Understanding the unique requirements of honey producers, we have tailored our equipment to handle various packaging formats, including jars, bottles, and pouches, all while maximizing automation and reducing labor costs. Our machinery is designed to accommodate varying viscosity levels and packaging speeds, making it perfect for operations of all sizes. With a focus on precision and reliability, our equipment not only enhances productivity but also minimizes waste, supporting sustainable practices within the industry. What sets our offerings apart is the unparalleled service and expertise that accompany every purchase. Our dedicated team of professionals provides comprehensive support, from initial consultation and equipment selection to installation and ongoing maintenance. This commitment to customer satisfaction ensures that our clients receive not just machinery, but a complete solution tailored to their specific needs. As the market continues to grow, partnering with an expert in honey packing equipment will provide your business with a competitive edge in delivering premium products to consumers worldwide.

Honey Packing Equipment For the Current Year Service Backed by Expertise

| Equipment Type | Features | Production Capacity (kg/h) | Energy Consumption (kW) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Semi-Automatic Filler | Adjustable filling volume, user-friendly interface | 500 | 2.5 | 6 |

| Fully Automatic Sealer | High-speed sealing, integrated labeling | 1200 | 3.0 | 12 |

| Labeling Machine | Automatic date coding, adjustable label sizes | 800 | 1.5 | 8 |

| Honey Filtering System | Multi-stage filtration, easy to clean | 1000 | 1.2 | 9 |

| Conveyor System | Modular design, variable speed control | 1500 | 4.0 | 10 |

Related Products