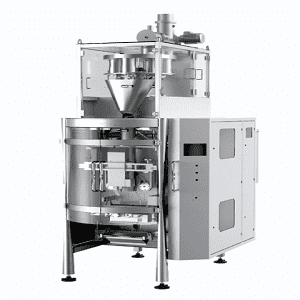

Top China Manufacturer of Oil Cake Packing Machines for Efficient Production

Our Oil Cake Packing Machine is designed with precision to meet the demands of modern packaging processes. As a manufacturer based in China, we understand the unique needs of the B2B market, ensuring that our machines deliver efficiency and reliability. I’ve experienced firsthand how this equipment excels in both speed and accuracy, making it perfect for businesses looking to scale their operations. With a focus on durability, our machine is built to withstand high-volume production while maintaining consistency in packaging. The user-friendly interface means that your team can operate it with ease, allowing for a smooth workflow. I believe investing in our Oil Cake Packing Machine will elevate your production capabilities and enhance your product’s market presence. Let's connect and explore how our manufacturing expertise can meet your specific needs!

Oil Cake Packing Machine Factory-Direct Excellence Custom Solutions,

In the competitive landscape of food processing, the efficiency and reliability of packaging machinery are paramount. For buyers seeking advanced solutions, a factory-direct offering provides a significant advantage. This approach not only ensures cost-effectiveness but also allows tailored customization to meet specific production needs. The oil cake packing machine is one such essential piece of equipment, especially in industries that require precise handling and packaging of by-products from oil extraction. Investing in an oil cake packing machine means optimizing your production line with top-tier technology designed for durability and high performance. With a focus on quality and innovation, these machines facilitate increased productivity while minimizing waste. The versatility of customization options ensures that from small-scale enterprises to large manufacturing facilities, every customer can find a solution that aligns with their operational demands. By leveraging direct factory relationships, procurement agents can also benefit from shorter lead times and enhanced service support, maximizing overall operational efficiency. Moreover, as sustainability becomes a crucial focus for global industry players, these machines are designed with eco-friendliness in mind, reducing the carbon footprint associated with packaging processes. Buyers looking to enhance their supply chain and meet evolving consumer demands will find that investing in cutting-edge packaging solutions is a vital step toward future-proofing their business. Embracing innovation in packaging not only meets current market needs but also positions companies as leaders in a rapidly changing industry.

Oil Cake Packing Machine Factory-Direct Excellence Custom Solutions

| Machine Model | Production Speed (bags/hour) | Bag Type | Power (kW) | Dimension (mm) |

|---|---|---|---|---|

| Model A | 50 | Plastic | 5.5 | 1200 x 800 x 1500 |

| Model B | 70 | Paper | 7.5 | 1500 x 900 x 1600 |

| Model C | 60 | Woven | 6.0 | 1400 x 850 x 1550 |

| Model D | 80 | Composite | 8.0 | 1600 x 950 x 1650 |

Related Products