Wholesale Pillow Packing Machinery from Trusted Manufacturers

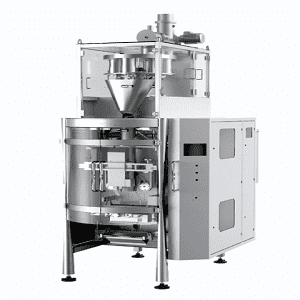

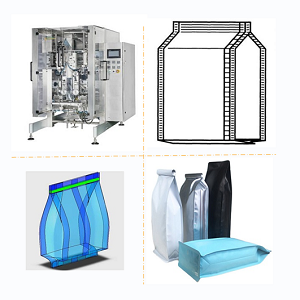

As a buyer in the fast-paced packaging industry, I understand the importance of reliable equipment. Our Pillow Packing Machinery stands out for its efficiency and durability, making it a perfect choice for wholesale manufacturers aiming to boost productivity. I’ve seen how this machine can streamline operations, reduce labor costs, and ensure consistent packaging quality. With various customizable features, it's designed to cater to different product sizes and shapes, making it ideal for diverse applications. I’ve partnered with trusted manufacturers who prioritize innovation and customer satisfaction. This machinery not only meets rigorous industry standards but also enhances the overall aesthetic of your product packaging. Investing in our Pillow Packing Machinery means you’re choosing a solution that adapts to your business needs, supports scalability, and ultimately drives profit. Let’s elevate your packaging process together!

Pillow Packing Machinery in 2025 Factory-Direct Excellence

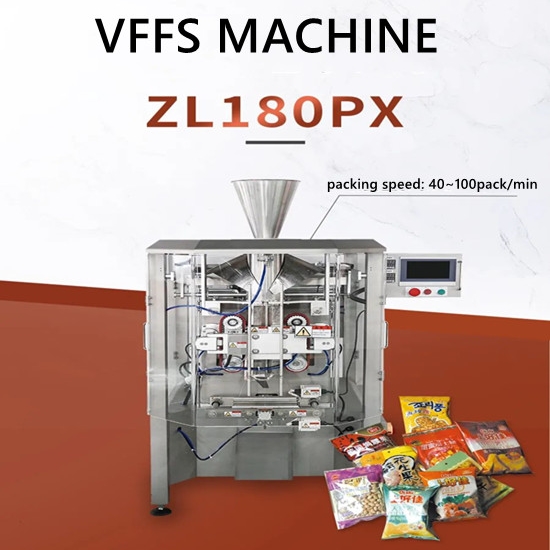

In the fast-evolving landscape of packaging technology, the demand for innovative and efficient pillow packing machinery is on the rise. As we look ahead to 2025, manufacturers are increasingly seeking solutions that not only enhance operational efficiency but also meet dynamic market demands. The latest advancements in pillow packing machinery offer features like automated processes, increased speed, and versatility in handling various packaging materials, positioning these machines as essential assets for businesses aiming to optimize their production lines. Investing in factory-direct pillow packing machinery empowers global buyers to benefit from cost-effective solutions that reduce overheads while ensuring high-quality standards. By sourcing directly from the manufacturer, businesses can expect better customization options to tailor machinery to their specific needs, whether for food products, pharmaceuticals, or consumer goods. Furthermore, a factory-direct approach guarantees ongoing support, ensuring that buyers receive timely maintenance and updates, which is crucial for maintaining optimal productivity. As we approach 2025, embracing technological advancements in pillow packing machinery will be vital for companies aiming to enhance their competitive edge. With features like IoT integration and smart analytics, businesses can monitor operations in real time, enabling data-driven decisions that optimize production efficiency. The future of packaging lies in these innovative solutions, paving the way for streamlined processes and a sustainable approach to manufacturing.

Pillow Packing Machinery in 2025 Factory-Direct Excellence

| Model | Production Speed (bags/min) | Bag Size (mm) | Power Consumption (kW) | Features |

|---|---|---|---|---|

| PillowPack 1000 | 60 | 200-400 | 2.5 | Automated, High Precision |

| PillowPack 2000 | 100 | 150-350 | 3.0 | Compact Design, Easy Cleaning |

| PillowPack 3000 | 80 | 100-300 | 4.0 | Energy Efficient, User-Friendly |

| PillowPack 4000 | 120 | 250-450 | 5.5 | Versatile, Smart Technology |

| PillowPack 5000 | 150 | 200-500 | 6.0 | High Output, Advanced Safety |

Related Products