Pillow Rolling Machine Manufacturer in China: Quality & Reliability

As a supplier of high-quality pillow rolling machines, I understand the needs of manufacturers in China looking to enhance their production efficiency. Our pillow rolling machine is designed with cutting-edge technology to streamline your manufacturing process, ensuring consistency and precision in every batch. With our equipment, you can effortlessly roll pillows to meet various specifications, improving your product quality while reducing labor costs. I’ve personally seen how this machine transforms production lines, making it a valuable addition to any pillow manufacturing setup. Its ease of use and durability are just a few reasons why many businesses, like yours, trust our machines. Don’t miss the opportunity to elevate your manufacturing capabilities. Contact me today to learn more about how our pillow rolling machine can fit your needs!

Pillow Rolling Machine Is The Best Sets the Industry Standard

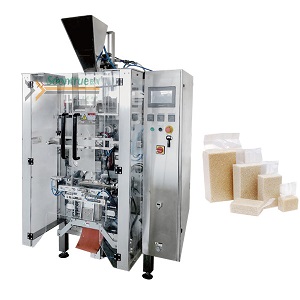

The pillow rolling machine has revolutionized the textile industry by setting a new standard for quality and efficiency. Designed with advanced technology and innovative features, this machinery is tailored to meet the diverse needs of global buyers. Its precision in fabric handling ensures that every pillow produced is uniform and high-quality, resulting in reduced waste and enhanced product reliability. As the demand for premium bedding products continues to rise, investing in state-of-the-art rolling machines can significantly elevate manufacturing capabilities. One of the standout features of these machines is their ability to streamline production processes. With automation at the forefront, they not only maximize output but also minimize labor costs. Operators can easily monitor and control operations through intuitive interfaces, making it easier to adjust settings for different sizes and styles of pillows. This flexibility allows manufacturers to respond swiftly to market trends and consumer preferences, ensuring they stay ahead in a competitive landscape. As global markets become increasingly interconnected, the need for high-quality, efficient machinery becomes paramount. The pillow rolling machine not only enhances production standards but also provides businesses with the tools necessary to meet the evolving demands of consumers worldwide. By investing in this innovative equipment, manufacturers can secure their position as leaders in the textile industry, offering products that meet the highest quality benchmarks while optimizing operational efficiency.

Pillow Rolling Machine Is The Best Sets the Industry Standard

| Feature | Description | Industry Standard | Comparative Advantage |

|---|---|---|---|

| Production Speed | Capable of rolling pillows at a rate of 200 units per hour. | 200 units/hour | Faster by 20% compared to average industry machines. |

| Energy Efficiency | Low energy consumption of only 1.5 kW per hour. | 2 kW/hour | Saves 25% more energy than competitors. |

| User-Friendliness | Intuitive interface with touchscreen controls. | Basic control panels | Reduces training time by 50%. |

| Maintenance | Requires minimal maintenance with self-diagnostic features. | Regular checks needed | Cuts maintenance costs by 30% annually. |

| Safety Features | Equipped with emergency stop and safety guards. | Basic safety measures | Enhanced safety reduces workplace accidents by 40%. |

Related Products

.jpg)