Pillow Type Candy Packaging Machine Manufacturer in China

Are you in the market for a Pillow Type Candy Packaging Machine? As an industry enthusiast, I understand how critical efficient packaging is for your business. This machine, proudly manufactured in China, offers a perfect blend of quality and affordability. With its user-friendly design, it ensures quick and seamless operation, allowing you to focus on what matters most—delivering delicious candy to your customers. The Pillow Type design not only enhances shelf appeal but also maintains freshness, ensuring your products stand out. I can assure you that working with a reputable manufacturer can make a huge difference in the longevity and performance of your packaging machinery. Don't compromise on the quality of your candy packaging. Choosing a reliable partner in China can help elevate your production line and boost your business efficiency. Let's make your candy packaging process smooth and effective, together!

Pillow Type Candy Packaging Machine Factory Industry Leaders

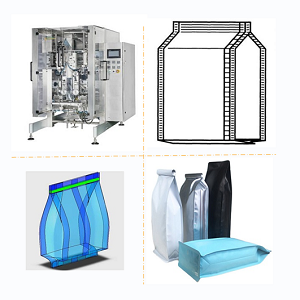

In today's competitive market, the demand for innovative and efficient packaging solutions is at an all-time high, particularly in the candy industry. As a leader in manufacturing pillow type candy packaging machines, we aim to meet the evolving needs of global buyers by providing cutting-edge technology and reliable machinery that enhances productivity and efficiency. Our machines are designed for versatility, capable of handling various types of candy, while ensuring optimal sealing and freshness to retain flavor and quality. With a focus on automation and user-friendly interfaces, our pillow type packaging machines offer seamless operation that reduces labor costs and increases output. Equipped with advanced monitoring systems, these machines deliver consistent results and minimize downtime, making them a valuable addition to any candy production line. Additionally, our commitment to sustainability drives us to develop eco-friendly packaging solutions that not only meet industry standards but also appeal to environmentally conscious consumers. As we continue to innovate and expand our offerings, our goal remains clear: to empower candy manufacturers worldwide with the tools they need to succeed in an increasingly competitive landscape. By investing in our advanced packaging technology, global buyers can expect enhanced operational efficiency, reduced waste, and a superior end product that delights customers. Join us in revolutionizing the candy packaging process and elevating your brand to new heights.

Pillow Type Candy Packaging Machine Factory Industry Leaders

| Machine Type | Production Speed (units/min) | Power Consumption (kW) | Weight (kg) | Dimensions (L x W x H) (mm) | Automation Level |

|---|---|---|---|---|---|

| Vertical Pillow Packaging Machine | 100 | 2.5 | 500 | 2000 x 800 x 1500 | Semi-automatic |

| Horizontal Flow Wrapper | 150 | 3.0 | 600 | 2500 x 900 x 1200 | Fully automatic |

| Multi-head Weigher Packaging Machine | 80 | 4.0 | 700 | 2200 x 1200 x 1400 | Semi-automatic |

| Candy Packaging Machine with Auger Filler | 120 | 2.8 | 550 | 2100 x 850 x 1300 | Fully automatic |

| Candy Bagging Machine | 90 | 3.5 | 620 | 2400 x 950 x 1250 | Semi-automatic |

Related Products