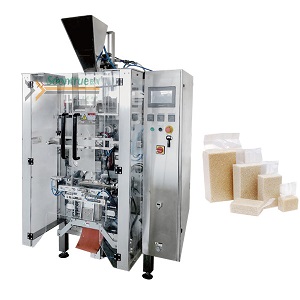

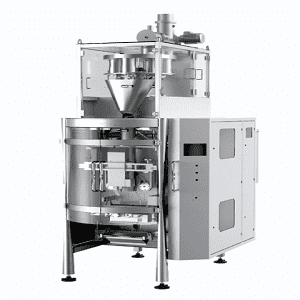

Top China Manufacturer of Rice Packing Production Line Solutions

Our Rice Packing Production Line is your ultimate solution for efficient packaging in the rice industry. As a seasoned manufacturer based in China, we understand the unique challenges that businesses face when it comes to packaging. That's why we’ve engineered a comprehensive line that combines advanced technology with user-friendly operation. I've seen firsthand how our production line increases productivity and reduces waste, making it a smart investment for your business. From precise weighing to high-speed filling and sealing, every aspect is designed to meet your needs. The durability of our machines ensures long-lasting performance, which means less downtime and more output for you. Consider partnering with us to elevate your packaging process. Whether you’re a small business or a large manufacturer, our Rice Packing Production Line can be tailored to fit your specific requirements. Let’s work together to streamline your operations and boost your bottom line!

Rice Packing Production Line Application Market Leader

In the dynamic landscape of food production, the rice packing production line has emerged as a cornerstone for efficiency and quality assurance. As global demand for packaged rice continues to surge, leading manufacturers are implementing sophisticated machinery designed to streamline processing and adhere to stringent quality standards. An advanced rice packing production line not only maximizes operational efficiency but also significantly reduces labor costs, ensuring that businesses can maintain a competitive edge in both local and international markets. The application of an automated rice packing production line encompasses various essential functions, including weighing, filling, sealing, and labeling. Automation minimizes human error, enhances productivity, and guarantees precision in every stage of the packing process. Moreover, modern technology integrated into these systems allows for real-time monitoring and data analysis, empowering manufacturers to optimize their operations and respond swiftly to market trends. Sustainability practices are also being prioritized, with machinery designed to reduce waste and energy consumption, aligning with the growing emphasis on eco-friendly production processes globally. For procurement professionals looking to invest in rice packing solutions, the key lies in selecting equipment that combines innovation with reliability. Collaborating with industry experts ensures that buyers have access to the latest advancements in packaging technology while receiving tailored solutions that cater to their unique operational requirements. The right investment not only enhances productivity but also reinforces a brand's commitment to quality and consumer satisfaction in an increasingly competitive marketplace.

Rice Packing Production Line Application Market Leader

| Application Area | Market Share (%) | Growth Rate (%) | Key Benefits |

|---|---|---|---|

| Retail Packing | 30% | 5% | Improved shelf life, Increased sales |

| Bulk Packing | 25% | 3% | Cost-efficiency, Reduced packaging waste |

| Export Packaging | 20% | 4% | Compliant with international standards, Secure transport |

| Automated Solutions | 15% | 6% | Increased efficiency, Reduced labor costs |

| Green Packaging | 10% | 8% | Eco-friendly materials, Consumer preference |

Related Products