Wholesale Semi-Automatic Filling Machine from Leading Manufacturers

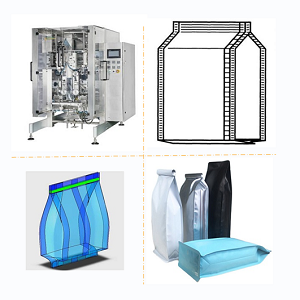

As someone deeply engaged in the packaging industry, I understand the importance of efficiency and reliability in production lines. That's why I highly recommend our semi-automatic filling machine, designed specifically for wholesale buyers and manufacturers. This machine streamlines your filling process, reducing labor costs while enhancing productivity. With its user-friendly interface, you can easily adjust settings to accommodate different product types and volumes, making it versatile for various applications. The robust construction ensures durability, meaning you’ll enjoy a long operational life with minimal maintenance. By choosing our semi-automatic filling machine, you're not just investing in equipment; you’re optimizing your entire production workflow. Whether you’re filling liquids, powders, or granules, this machine meets your business needs while allowing for scalability as your production demands grow. Get in touch to learn how we can support your operations and help you achieve greater efficiency!

Semi-automatic Filling Machine Industry Giant Pioneers in the Field

In the dynamic landscape of manufacturing, the semi-automatic filling machine industry is experiencing remarkable growth, driven by the increasing demand for efficiency and precision across various sectors. As businesses seek to optimize their production lines, the innovative solutions offered by leading manufacturers are setting new benchmarks for quality and reliability. These giants in the field are dedicated to advancing technology, providing businesses with robust machinery that enhances productivity and minimizes operational costs. The versatility of semi-automatic filling machines makes them a valuable asset for companies ranging from small startups to large-scale enterprises. Designed to accommodate various liquid and viscous products, these machines ensure accuracy and speed, reducing the risk of human error while maintaining consistent product quality. As sustainability becomes a priority, the latest models are also being engineered with energy-efficient features and minimal waste production, aligning with global efforts toward eco-friendliness. For global buyers, investing in top-tier semi-automatic filling machinery translates to a strategic advantage in a competitive marketplace. By partnering with industry leaders, businesses can gain access to cutting-edge technology, comprehensive support, and tailored solutions that cater specifically to their operational needs. Embracing these advancements not only fosters growth and innovation but also positions companies as frontrunners in their respective industries, ready to meet the challenges of the future.

Semi-automatic Filling Machine Industry Overview

| Application | Machine Type | Production Capacity (Liters/hour) | Key Features | Customization Options |

|---|---|---|---|---|

| Beverages | Piston Filling Machine | 200 | Adjustable filling speed, easy cleaning | Customized nozzle sizes |

| Cosmetics | Vacuum Filling Machine | 150 | Prevents bubble formation, precise filling | Custom color and size options |

| Pharmaceuticals | Peristaltic Filling Machine | 100 | Non-contact filling, high precision | Multiple channel options |

| Food Products | Gravity Filling Machine | 250 | Simple operation, economical | Customizable filling heads |

| Chemicals | Electronic Filling Machine | 300 | Automation, accuracy in low viscosity | Programmable controls |

Related Products