Wholesale Small Powder Filling Machine from Top Manufacturers

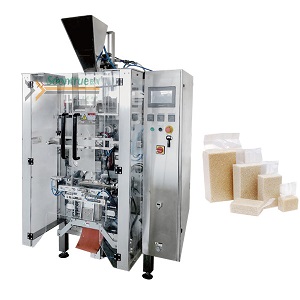

When I think about efficiency in packaging, the Small Powder Filling Machine stands out. Perfect for manufacturers and wholesalers like you, this powerful machine accelerates your filling process without sacrificing accuracy. Designed for small to medium-scale operations, it’s compact yet robust, easily fitting into tight spaces while still delivering top-notch performance. Its user-friendly interface makes operation a breeze, and with adjustable settings, I can customize the fill volume to meet my specific needs. If you're a manufacturer looking to streamline production or a wholesaler aiming to enhance your offerings, this machine will fit right into your workflow. Plus, its durability means I won’t have to worry about frequent replacements, saving costs in the long run. Investing in the Small Powder Filling Machine means boosting efficiency and maintaining quality—an essential step towards satisfying your clients and growing your business. Don’t miss out on maximizing your productivity!

Small Powder Filling Machine Sets the Industry Standard Leads the Global Market

In the rapidly evolving landscape of packaging solutions, small powder filling machines have emerged as a critical component for various industries including food, pharmaceuticals, and cosmetics. These machines not only enhance operational efficiency but also ensure precise filling, reducing wastage and maximizing output. As consumer demand for finely packaged products increases, businesses are keen to adopt technologies that set the standard for quality and performance. The latest advancements in small powder filling technology are designed to meet the diverse needs of global markets, enabling companies to remain competitive in a fast-paced environment. With a focus on automation and user-friendly designs, these machines offer manufacturers the flexibility to scale their production while maintaining high levels of accuracy. Advanced features like electronic volume control and customizable filling parameters set a new benchmark in the sector. Furthermore, compliance with international safety and quality standards assures buyers of the reliability and longevity of these machines, making them a smart investment for businesses aiming to enhance their production capabilities. As markets expand and the demand for packaged goods surges, selecting a high-quality small powder filling machine becomes essential for businesses aiming to lead in their industries. Investing in cutting-edge technology not only improves operational efficiency but also drives customer satisfaction through improved product presentation. In an increasingly competitive global market, equipping your production line with innovative filling solutions will ensure your company stays ahead of the curve.

Small Powder Filling Machine Sets the Industry Standard Leads the Global Market

| Model | Capacity (Bottles per Hour) | Filling Volume (grams) | Weight (kg) | Dimensions (cm) | Power (W) |

|---|---|---|---|---|---|

| PFM-100 | 1200 | 10-50 | 50 | 70 x 50 x 130 | 500 |

| PFM-200 | 1500 | 20-100 | 60 | 80 x 60 x 140 | 600 |

| PFM-300 | 1800 | 30-150 | 70 | 90 x 70 x 150 | 800 |

| PFM-400 | 2000 | 50-200 | 80 | 100 x 80 x 160 | 1000 |

Related Products

.jpg)