Wholesale Strapping Machine Manual from Leading Manufacturers

When it comes to optimal strapping solutions, I’ve come across the Strapping Machine Manual that really stands out. This manual is perfect for wholesale purchasers seeking reliable equipment from top manufacturers. It provides comprehensive guidelines covering everything from setup to maintenance, ensuring that your strapping operations run smoothly and efficiently. As someone who values efficiency in the packaging process, I appreciate the attention to detail in this manual. It's easy to follow, even for those who might be new to strapping machines. Plus, it includes tips on troubleshooting common issues, which has been a lifesaver in my experience. Whether you run a large warehouse or a small manufacturing unit, having this manual on hand can greatly enhance your workflow. Trust me, if you are in the market for dependable strapping solutions, this manual from reputable manufacturers will not disappoint. Make a wise investment for your business today!

Strapping Machine Manual Where Innovation Meets 2025 Custom Solutions,

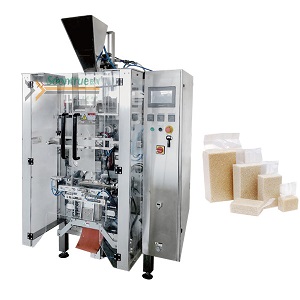

In today’s fast-paced manufacturing landscape, the demand for efficient packaging solutions is greater than ever. Strapping machines play a crucial role in securing products for shipping and storage, ensuring that they arrive safely at their destination. As we move toward 2025, the focus on customization and innovation is becoming paramount. Manufacturers are increasingly seeking machines that not only meet their current needs but can also adapt to evolving market demands. Our latest strapping machine manual embraces this ethos by introducing custom solutions that are designed to enhance productivity and efficiency. With advanced technologies and user-friendly interfaces, these machines streamline operations while maintaining the highest standards of quality. From adjustable tension settings to versatile strap options, each feature is engineered to provide a tailored approach for various industries, ranging from logistics to manufacturing. Moreover, sustainability is transforming the packaging sector. Our innovations are not just about speed and efficiency; they also prioritize eco-friendly materials and processes. By investing in state-of-the-art strapping solutions, businesses can not only improve their operational efficiency but also contribute to a more sustainable future. As we move forward, the integration of smart technologies will further elevate the capabilities of strapping machines, making them indispensable in the quest for operational excellence and adaptability in a competitive market.

Strapping Machine Manual Where Innovation Meets 2025 Custom Solutions

| Feature | Description | Benefit | Customization Options | Application Areas |

|---|---|---|---|---|

| Automatic Tension Control | Maintains consistent strap tension. | Improves package security. | Adjustable tension settings. | Logistics, distribution centers. |

| User-Friendly Interface | Intuitive touch screen controls. | Reduces training time. | Multiple language options available. | Manufacturing, packaging lines. |

| Eco-friendly Materials | Sustainable strap options. | Minimizes environmental impact. | Biodegradable and recyclable strapping. | E-commerce, food industry. |

| High-Speed Operation | Can strap up to 50 packages per minute. | Increases productivity. | Capability for bulk packaging solutions. | Warehousing, fulfillment centers. |

| Compact Design | Space-saving equipment footprint. | Ideal for limited spaces. | Custom size configurations. | Retail, small businesses. |

Related Products