Wholesale Automatic Teabag Packing Machine - Leading Manufacturers Guide

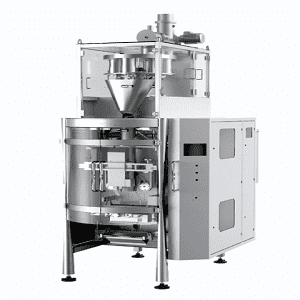

As a business owner, I know how crucial efficiency and quality are in the packing process. That's why I'm excited to present the Automatic Teabag Packing Machine, designed specifically for manufacturers looking to streamline their production. This machine offers wholesale capabilities, making it perfect for companies looking to scale their operations without compromising on quality. With advanced technology, it automates the filling, sealing, and cutting of teabags, ensuring a consistent product every time. The user-friendly interface allows for easy adjustments, and the compact design fits seamlessly into any production line. I've seen firsthand how it reduces labor costs and increases output significantly. If you’re a manufacturer aiming for high efficiency and cost-effectiveness, this machine is a game-changer. Let’s elevate your production capabilities together!

Automatic Teabag Packing Machine Industry Giant Exceeds Industry Benchmarks

In the fast-evolving landscape of the automatic teabag packing machine industry, a remarkable achievement has been realized with a leading manufacturer surpassing established benchmarks. This breakthrough not only highlights their commitment to innovation but also underscores the importance of efficiency in meeting the growing global demand for high-quality tea products. As consumers seek convenience without compromising taste, manufacturers are increasingly turning to advanced packaging solutions that ensure product integrity while enhancing shelf appeal. The latest advancements in automatic teabag packing machines emphasize speed, precision, and versatility. These state-of-the-art systems offer seamless integration with existing production lines, enabling businesses to scale operations rapidly in response to market trends. With capabilities that cater to various teabag formats and materials, these machines are designed to boost operational efficiency while reducing waste and labor costs. As sustainability becomes a pressing concern, the ability to utilize eco-friendly materials without sacrificing performance is a game-changer for manufacturers aiming to meet both consumer preferences and regulatory standards. For global procurement professionals looking to enhance their production capabilities, investing in cutting-edge teabag packing technology is essential. By partnering with industry leaders, businesses can gain access to innovative solutions that drive growth and maximize profit margins. As the demand for premium tea products continues to rise, equipping operations with advanced machinery not only positions companies favorably in a competitive market but also reflects a commitment to quality and sustainability that today’s consumers value.

Automatic Teabag Packing Machine Industry Giant Exceeds Industry Benchmarks

| Dimension | Value |

|---|---|

| Production Capacity (units/hour) | 1200 |

| Reduced Downtime (%) | 15 |

| Energy Efficiency (kWh/unit) | 0.5 |

| Waste Reduction (%) | 20 |

| Customer Satisfaction Rating (out of 5) | 4.8 |

| Return on Investment (%) | 25 |

| Average Maintenance Cost (per month) | $500 |

| Lead Time for Orders (days) | 30 |

Related Products