Top China Manufacturer of Filling Machines for Olive Oil

When it comes to efficient and reliable production, our filling machines for olive oil are designed to meet the needs of manufacturers in China. I understand the unique challenges you face in your operations, and I've seen firsthand how our machines can streamline the filling process, ensuring consistency and quality in every bottle. With a focus on durability and ease of use, these machines minimize downtime and boost productivity, allowing you to focus on what you do best—producing top-notch olive oil. As a trusted manufacturer, we prioritize customer satisfaction and offer support tailored for your specific requirements. Whether you're scaling up production or just starting out, our filling machines are an investment you won't regret. Let’s enhance your production line and satisfy your customers with every fill!

Filling Machines For Olive Oil Application Guarantees Peak Performance

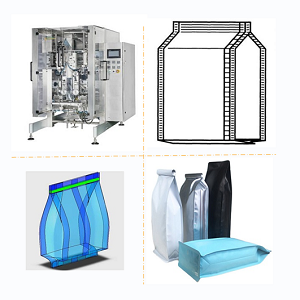

In the world of food production, the quality of packaging is as crucial as the product itself, particularly for high-value items like olive oil. The implementation of advanced filling machines specifically designed for olive oil applications can significantly enhance operational efficiency and ensure product integrity. These machines are engineered to handle the unique properties of olive oil, such as its viscosity and sensitivity to light and air, which are vital to preserve its flavor and nutritional benefits. Investing in cutting-edge filling technology not only guarantees consistent fill levels and minimizes waste but also boosts overall productivity. Machines equipped with smart controls and automation features allow for quick changeovers between different bottle sizes and types, catering to the diverse needs of global markets. By ensuring precise filling and sealing, businesses can maintain compliance with international quality standards, building trust with consumers who seek premium olive oil products. As global demand for authentic and high-quality olive oil continues to rise, sourcing reliable equipment is essential for producers looking to maintain a competitive edge. Embracing innovative filling solutions can lead to significant cost savings, reduced downtime, and ultimately, enhanced profitability. With the right technology in place, companies can focus on what they do best—producing outstanding olive oil while ensuring it reaches consumers in optimal condition.

Filling Machines For Olive Oil Application Guarantees Peak Performance

| Machine Model | Filling Speed (L/min) | Tank Capacity (L) | Precision (%) | Power Requirement (kW) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 30 | 250 | 99.5 | 5 | 150 |

| Model B | 45 | 300 | 99.8 | 7.5 | 180 |

| Model C | 25 | 200 | 99.0 | 4 | 120 |

| Model D | 50 | 350 | 99.7 | 10 | 220 |

Related Products