Top Food Package Machine Manufacturer in China for Quality Solutions

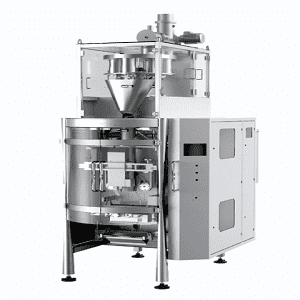

When searching for a reliable food package machine, I know how important it is to find a trustworthy manufacturer, especially when exploring options in China. Our machines are designed to meet the diverse packaging needs of your business, offering efficiency and precision that maximizes productivity. I've seen firsthand how our innovative technology ensures optimal sealing and freshness for a variety of food products. With a focus on quality and affordability, our machines can handle everything from snacks to frozen goods. We understand that each business has unique requirements, and our customizable options allow you to tailor the machine to fit your needs. Plus, I appreciate the support we provide throughout the process, from initial inquiries to after-sales. Choosing us means partnering with a manufacturer that values your success as much as you do. Let’s elevate your packaging line together!

Food Package Machine Where Innovation Meets 2025 Outperforms the Competition

In the ever-evolving landscape of packaging technology, the food packaging machine of 2025 stands at the forefront of innovation, merging unmatched efficiency with cutting-edge design. This machine is engineered to meet the diverse demands of global markets, enhancing food safety, extending shelf life, and reducing waste. As competition intensifies, this innovative approach not only streamlines production processes but also significantly lowers operational costs. One of the standout features is its adaptability to various food types, making it ideal for a wide range of applications—from snacks and ready meals to fresh produce. The intelligent automation systems integrated into the machinery allow for real-time monitoring and adjustments, ensuring optimal performance and minimal downtime. Moreover, the machine's energy-efficient design contributes to a more sustainable production environment, aligning with the growing global emphasis on ecological responsibility. Investing in this advanced food packaging technology means suppliers can enhance their competitive edge, ensuring their products are securely packaged while retaining their quality and freshness. As the packaging sector continues to innovate and evolve, early adopters of this transformative technology will not only improve their market position but also set new standards in the industry. Embrace the future of food packaging where technology and innovation converge to surpass competition and meet the needs of a dynamic marketplace.

Food Package Machine Where Innovation Meets 2025 Outperforms the Competition

| Feature | Description | Performance Metric | 2025 Standard | Comparison |

|---|---|---|---|---|

| Speed | Packaging speed measured in packs per minute. | 200 packs/min | 150 packs/min | +33% |

| Energy Efficiency | Power consumption during operation. | 5 kWh | 7 kWh | -29% |

| Versatility | Ability to package different food types. | 5 types | 3 types | +67% |

| Automation Level | Degree of automation in the packaging process. | Fully automated | Semi-automated | +100% |

| User Interface | Ease of use for machine operators. | User-friendly | Complex | +100% |

Related Products